Welding Shop

The Welding Lab has multiple welders including a TIG, MIG and Plasma cutter!The welding shop consists of a 280 sq. ft room. It contains a Welding Table, MIG Welder, TIG Welder, Spot Welder, Plasma Cutter, Blasting Cabinet as well as a Fume Boom for ventilation. There is a first aid kit located on the east wall.

The current Aces of the Welding Shop are Wyatt Bertis (wbertis22@georgefox.edu).

Schedule

View the most up-to-date Welding Shop schedule on this Google Sheet.

Equipment Overview

| Name | Company | Model | Current Ace ⠉ |

|---|---|---|---|

| Blast Cabinet | Skat Blast | SC-40 | Needed |

| Buffers | Baldor | 332B | Needed |

| MIG Welder | Miller Electric | Millermatic 210 | Wyatt Bertis |

| Pedestal Grinder | Baldor | 332B | Needed |

| Plasma Cutter | Miller | Spectrum 875 | Needed |

| Spot Welder | Miller | LMSW-52 | Needed |

| TIG Welder | Miller | Syncrowave 250DX | Wyatt Bertis |

3 commandments

1. Safety First

Safety First is the rule we hold highest of the three. This rule applies to both the safety of you as well as others

Keeping yourself safe in the Welding Lab is very important, as there are possibilities for accidents if you don't follow the safety guidelines. The following rules must be followed at all times.

These are the basic rules for safety in the Welding Lab:

- Safety glasses must be worn at all times.

- No horseplay in the shop.

- Don’t do anything distracting to yourself or others while operating equipment.

- Do not wear any loose clothing, jewelry, or landyards.

- No open toed shoes.

- Hair will not extend bellow the collar.

- Gloves and helmet must be worn when welding is in progress.

- No bare exposed skin when welding.

- Food or drink is not allowed in the Welding Lab.

- Do not attempt to operate equipment that you have not been certified on by GFU engineering personnel.

- Do not argue with volunteers or shop staff. Contact Justin Johnson if you have issues that need to be resolved.

- Do not operate welding equipment without a buddy present. Never operate equipment alone in the shop.

- Reset the space. A clean space is a safer space.

- If you see a safety violation inform the person immediately and encourage them to comply with the policies.

- Don’t do anything that would require an additional rule to be added to this list.

2. Reset the Space

The Welding Lab has a specific organization to it. Put whatever you use back where it belongs. There is a place for everything and everything has a place. This rule applies to everything in the space. If you use a tool, put it back. If you use a pen, put it back. Do not leave your projects in the Welding Lab unless you have made prior arrangements. Throw away your trash and recycling.

Now, we understand that sometimes you need to leave projects out. Maybe you are in the middle of a large project and you need something left overnight. In cases like this, it is okay, but you NEED to make prior arrangements with Nick or Justin.

Please put back the equipment the way you found it. Make sure the welding gas is SHUT OFF. The welding cables should be neatly wrapped back onto the welders after they have been allowed to cool. Never step on or kink the welding cables and lines.

Always put any unused materials back on the storage shelf, and throw away unusable scrap.

Sweep the floor and welding table when done.

Make sure to shut off the lights and room ventilation before leaving.

Always leave the space better than you found it.

3. Be Professional

This commandment has two sides to it. It covers the idea of acting like professional (which Webster’s defines as “exhibiting a courteous, conscientious, and generally businesslike manner in the workplace”). The term also describes the standards of education and training that prepare members of the profession with the particular knowledge and skills necessary to perform their specific role within that profession. Hopefully, you are learning both of these as part of your education at George Fox University. In the Welding Lab we expect you to develop as a courteous, conscientious, and skilled craftsman, understanding the tools and equipment in the Maker Hub and how to use them effectively.

Being a professional has some obvious ramifications in terms of behavior. First, be Christlike. Think of others better than yourselves. Share. If you have been welding for a prolonged time and someone else is waiting for the machine, let them use the machine for a while. This is being a professional.

If you are learning to weld, and you can't something to work the way you want - ASK SOMEONE! Learn! Become a professional. Learn the craft. This is an educational space. You might think it will be quick and you can just get it done “your” way and not learn how to do it correctly. Be a Professional and learn the proper way, and then be available to teach others.

One very important, and likely difficult part of being a professional is to correct others when they are not being professional. It is your responsibility to speak up when you see somebody doing something inappropriate. If you see somebody doing something unsafe, not resetting the space, or being unprofessional, the professional thing to do is to remind them of the three commandments and ask them politely to correct their action. This is OUR space, not any individual's. As a group, we expect everyone in the space to keep the space safe, clean, and operable for everyone.

If someone acts disgracefully unprofessional to you in the Welding Lab, you are welcome to bring the issue to Justin or Nick's attention.

General Welding Knowledge

Welding is the process of joining metals together. It is a form of additive manufacturing. There are several different types of welding, and the Welding Lab uses most of these including spot welding.

In the Welding Lab, metals are joined together using MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), Stick and spot welding.

Each welder has its own special purpose and benefits. MIG is fast and much easier to learn than TIG welding. Spot welding is only used with sheet metal. TIG welding produces very clean welds and the heat is more confined to a smaller area. TIG will also allow you to weld very thin metals.

There are common places of potential failure which you should watch for every print. The following points of failure specifically apply to FDM prints.

- Adhesion:

- When the print first starts, it is prudent to ensure that the filament is properly adhering to the build plate.

- Watch the print until the first dozen layers have been printed to make sure it is starting off successfully.

- The print can start sliding around the plate at anytime, although it is much more likely to fail toward the beginning of the print.

- A tall and skinny print is much more likely to struggle with adhesion than a short and stout print. Taking time to discern the best orientation for your print is always a good call.

- Adding a raft (sometimes called a brim) will also help if you print is struggling with staying adhered to the plate.

- Clogging

- Sometimes the extruder will clog causing the print to fail.

- This typically can be seen when a clump of filament balls up at the end of the nozzle.

- If this occurs, immediately cancel the print and remove the clumped filament. Make sure that the nozzle is still able to extrude filament, if not, you may need to open up the extruder and clean it. Keep working on it until you are able to extrude filament again.

- Air Extruding

- This means that the extruder thinks it is extruding filament when it really is not.

- Immediately cancel the print. Then restart the print.

- If the printer is still air extruding, cancel the print and unload the filament. You can try reloading and starting the print again.

- If the problem persists, you will probably need to take the extruder apart and clean it out before attempting any further prints.

1. Welder Types

There are many different types of printers, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Selective Laser Melting (SLM), Digital Light Processing (DLP), Electronic Beam Melting (EBM), Laminated Object Manufacturing (LOM), Binder Jetting (BJ)... Each printer type employs different materials. The Prototype Lab has FDM and SLA machines.

Information about FDM and SLA printers and which machines these are and what materials they can use which. In each printer's page, one can simply link it to this so they don't have to describe materials, just simply state which ones are used with it. Mostly this is all here so I remember to do it or someone else sees it and wants to do it.

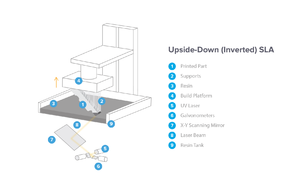

SLA Printing

Stereolithography, SLA, is a part of the manufacturing technology of vat polymerization. This means a light source (laser) is used to cure liquid resin into a hard plastic. The Form 2 is the only 3D printer that the Prototype Lab has that is an SLA printer. It utilizes the Upside Down or Inverted orientation. The resin tank has a clear bottom with a surface the resin will not stick to. This allows the resin to cure against the bottom of the tank. The build platform is lowered into the resin until it is hovering above the bottom surface of the tank, as far away as the height of the layer to be constructed. The laser is directed through the bottom of the tank and cures a layer of resin onto the build platform. Then, the resin tank slides over and the build platform raises. The wiper will then sweep across the tank to circulate the resin. The build platform will lower again, and the process will be repeated until the print is completed. Due to friction caused by de-laminating every layer, every part should be canted in its orientation. This means the part should be angled to reduce the cross sectional area needing to be shifted to de-laminate each layer. This de-lamination also causes the Form 2 to be the Prototype Lab's slowest 3D printer. Once a part is finished on the Form 2, it must be removed off of the build plate. Try to avoid scraping the build plate when removing parts. Any excess resin must be washed off using the Form Wash, the part must be air dried so that any isopropyl alcohol from the Wash has evaporated, the part should be cured in the Form Cure, and supports should be clipped off. Any remaining support marks can be sanded off if so desired. Extra information on SLA Printing can be found here.

FDM Printing

Fused Deposition Modeling (FDM) printers use a thermoplastic filament, which is heated to its melting point, then extruded to create layers which then build an object. There are many different types of FDM printers. Some use a modeling material and a support material, some just use a modeling material which when creating support will use a different style of layering that allows the filament to break off easily, some are able to use multiple filaments at once allowing for multicolored objects to be created.

Both Stratasys printers (Dimension and F370) use soluble support filament (the support filament dissolves in a heated sodium hydroxide bath), the Prusa printers use only a model material, and the Markforge printer only uses model material as well (however it will layer another filament for extra support).

The filament for these printers comes in spools (basically thin plastic ropes that are wound up). The filament is fed through an extruder head, heated to the desired temperature, then extruded (similar to what happens with a hot glue gun).

FDM printers can work with various materials, in the Prototype Lab we mainly stick to ABS which is used by the Stratasys machines and PLA which is used by the Prusas. The Markforge uses a material called Onyx (nylon and plastic mix) and will layer in another filament such as Carbon Fiber, Kevlar, etc.

General Welding Knowledge

Welding is the process of jointing metals. The laser cutter follows a predetermined pattern to engrave or cut the material. Laser cutting is a great way to get a professional-looking surface finish.

- Can be used for many different materials ranging between wood, glass, rock, plastics, and even engraving Hydroflasks. At this time, the laser cutter in the Prototype Lab is not set up for metal etching.

- Works best on flat surfaces or cylinders with constant diameters.

There are a couple common steps that must be done correctly when using the laser cutter:

- Always make sure that the lens and cone are clean before starting a print.

- Correctly focus the laser above the material, using the correct focusing tool for the lens type.

- Choose the correct material profile for the material you are using.

- Clean the bed of the laser cutter when you are finished.

Foxtale Certification

Before working with any of the equipment in the prototype lab you will need to take the general lab quiz as well as the specific quiz for each machine you are trying to use. The enrollment code for all of the quizzes is MakerHub.