Difference between revisions of "Vertical Wood Bandsaw"

(→Safety) |

|||

| Line 76: | Line 76: | ||

==Certification== | ==Certification== | ||

| − | [https://foxtale.georgefox.edu/moodle/ | + | [https://foxtale.georgefox.edu/moodle/enrol/index.php?id=30801 Foxtale Course] |

==Troubleshooting== | ==Troubleshooting== | ||

Revision as of 15:36, 22 August 2019

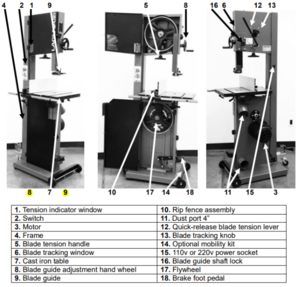

Make: Laguna

Model: mband 14BX220-250

Ace: Needed (Makerhub@georgefox.edu).

Location: Wood Shop

Description

The bandsaw is generally defined as a saw blade in the form of an endless steel band that rotates around two or more wheels. This blade is a continuous metal band with teeth on one side. As the wheels rotate, so does the band, which creates the continuous sawing action. Because the direction of the blade is always downward toward the table, there is little danger (except for special cuts) that the wood will be thrown back at the operator, which is called a kickback. For safety reasons many woodworkers prefer the bandsaw especially when cutting small pieces. The unique feature of the bandsaw is that the workpiece can be rotated around the blade creating a curve. It is the tool most often used when curves have to be cut in wood. Because the bandsaw blade is fairly thin, it can cut thick stock with a minimum of horsepower. For this reason the bandsaw is often used when valuable pieces of wood are made into a thin piece of veneer.

Although the bandsaw is usually associated with cutting curves, a variety of straight cuts are easily made with the saw. In fact, it is often used to rip wood because it is much safer than a radial arm saw and also has a smaller saw cut, so it wastes less wood. This becomes very important when using expensive wood where waste must be kept to a minimum. The cut is safer because the force of the cut is straight down on the table; the work cannot be pulled back or kicked back, which sometimes happens with table or radial arm saws. The bandsaw can also cut very thick stock, which the radial arm, or table saw cannot do. The disadvantage of cutting with the bandsaw is that the surface finish of the cut is not as good as with the table or radial arm saw.

Documentation

Terminology

Training

Overview

Insert Text

Demonstration

To show a complete knowledge of the Wood Vertical Bandsaw, the student will cut out a curved shape using scrap wood.

General Procedure

- Make sure the blade guides and fence are in place. These are meant to help your cut, so it is crucial that these are in place.

- Instructions on adjusting can be found in the manual, but they should be fine by default. The ace should take care of such issues.

- Blade guides (p. 33-34)

- Fence (p. 35-37)

- Instructions on adjusting can be found in the manual, but they should be fine by default. The ace should take care of such issues.

- Adjust the upper blade guard so that it is just clearing the material being cut

- Make sure that the cutting teeth are facing down since the blade moves downward. Otherwise, it will not cut.

- Make sure that the blade has been properly tensioned (blade doesn’t have slack) and tracked (blade moves evenly and consistently as the wheels turn, doesn’t wander back and forth)

- Instructions on tensioning (p. 30) and tracking (p. 29) can be found in the manual

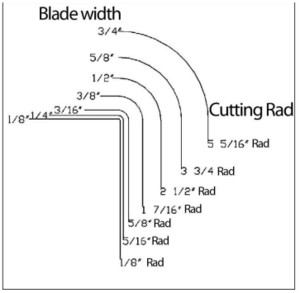

- Make sure the proper size and type of blade is in use

- Blade help is in the manual (p. 38-42)

- Turn the saw on. ‘1’ turns on, ‘0’ turns off.

- Hold the workpiece firmly against the table, flat side down.

- Push material into blade at a moderate pace, using a push stick if necessary at the end of the cut.

- Turn the machine off once the cut is complete.

- Remove the workpiece and reset the space.

Safety

- Don’t feed anything into the blade you don’t want cut. First off, it makes no sense and it could pull other stuff into the midst, like your own body. That isn't a good scenario, so let's prevent that.

- Plan out your cut before making it. Wasting material isn't a good idea, and it's more time consuming when you mess up.

- Be careful not to catch anything in the blade cutting curves.

- Use a push stick if necessary. Do not risk getting your hands too close to the blade .

- Hold work piece firmly on the table. It would be a shame if it flew somewhere and hit someone, then we'd have an interesting lawsuit to deal with...

Certification

Troubleshooting

- Suppose the bandsaw will not start.

- Check that the start switch is fully pulled out.

- Check that the yellow safety plug is fully engaged.

- Check that the electrical power cord is plugged into the power outlet.

- Check that the electrical supply is on (reset the breaker).

- Check that you have the correct power, 110V not 220V

- Suppose the machine will not stop.

- This is a very rare occurrence, as the machine is designed to be fail-safe. If it should occur and you cannot fix the fault, seek professional assistance. The machine must be disconnected from the power and never run until the fault has been rectified.

- Stop switch faulty. Replace the stop switch.

- Internal breaker faulty. Replace the breaker.

- Suppose the motor tries to start but will not turn.

- With the power disconnected from the machine, open the doors and try to turn the wheel by hand. If the wheel is not turning, check the reason for the jamming. Typical reasons are: guides too tight, wood jammed in the wheel. Adjust guides or remove jammed wood.

- Capacitor faulty. Replace the capacitor.

- Motor faulty. Replace the motor.

- Suppose the motor overheats.

- The motor is designed to run very hot, but should it overheat it has an internal terminal overload protector that will shut it down until the motor has cooled down and then it will reset automatically. If the motor overheats, wait until it has cooled down and restart. If the motor shuts down constantly, check for the reason. Typical reasons are dull blade, overfeeding the wood, motor cooling fan clogged or faulty, motor cooling fins clogged and excessive ambient temperature.

- Suppose there's a squeaking noise.

- Check that the motor cooling fan is not contacting the fan cover.

- Check the bearings.

- Check the drive belt.

- Check that the guides are adjusted correctly.

- Suppose the upper guide shaft is tight or loose.

- Clean and lubricate.

- Adjust rack and pinion.

- Bent rack. Replace the rack.

- Suppose the blade slows down during a cut.

- Loose drive belt. Re-tension the belt.

- Dull blade. Replace the blade or have it re-sharpened.

- Feeding the wood too fast. Slow down the feed rate.

- Insufficient set on the teeth (wood nipping the blade). Change blade for a blade with the correct set.

- Oil or dirt on the drive belt. Clean or replace the drive belts.

- Fence not aligned correctly. Align fence.

- Suppose the blade will not track on flywheels.

- Bad blade. Change the blade.

- Crown on the wheels worn or damaged tire. Dress the tires.

- Suppose the blade kicks.

- Bad blade. Replace the blade.

- Suppose the blade makes a clicking noise.

- Bad weld. Dress the weld or change the blade.

- Suppose the blade overheats.

- Dull blade. Change the blade or resharpen the blade.

- Pitch is too small for the depth of cut. Change to a blade with the correct pitch.

- Guides too tight. Adjust the guides.

- Wood too hard for the selected blade. Change the blade.

- Blade too thick for the diameter of the wheels. Change the blade.

- Machine vibrates.

- Machine not level on the floor. Re-level the machine ensuring that it has no movement.

- Damaged drive belt. Replace the belt.

Maintenance

General maintenance

Little maintenance is needed to upkeep the Wood Vertical Bandsaw. Refer to the table below for specific tasks.

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| General Cleaning | After each use | Student |

| Blade Change | When Dull | Ace |

| Rotate back blade guard 15 degrees | Every 8 hours of use | Ace |