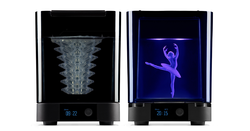

Formlabs Wash and Cure

The automated wash and cure process helps to unlock the parts peak mechanical properties and performance. [1]

Documentation

Training

Form Wash Specifics

The Form Wash uses isopropyl alcohol to remove resin. It's used to clean parts and the occasional build plate. Tools should be washed by hand using the alcohol squirt bottles.

Washing Basics:

- Each wash should be run an average of 10 minutes

- This time can be changed based off of the size/structural density of the part, with larger or more complicated parts requiring longer to wash

- Do not remove supports for the washing process

- After washing, remove the print to let it air dry before running it through the Form Cure

- Each resin has its own recommended setting for washing

Form Cure Specifics

Curing enables prints to reach their optimal material properties. This means that the strength and stability of each print will be maximized. The Form Cure uses heat and 405 nm light to cure the print, this light is the same wavelength as the laser that the Form 2 has. Using the Form Cure to cure the print is the final step of the printing process.

Curing Basics:

- Before placing the print in the Cure, the print needs to be completely dry after having exited the Wash

- Once the print is dry, it may placed inside of the Cure

- To do this, lift the lid, place the print on circular silver grate, and close the lid once finished

- The knob next to the screen can be used to scroll and click

- Choose the appropriate time and temperature for the resin of the print

- Times and temperatures vary with each resin

- Bulky or thick parts will require more cure time than small or thin parts

- Over-curing is always better than under-curing

- Supports can be most easily removed after the Cure has finished

The recommended setting can be found at Form Cure Time and Temperature Settings towards the bottom of the page under Form Cure Settings. Make sure the correct Material and Version are chosen so that the proper graph and settings are displayed for your print.