Prototype Lab

The prototype lab contains a group of 3D printers and a laser cutter (more to come in the near future)!

The Aces of the Prototype Lab are: Ben Kraske (bkraske16@georgefox.edu) and Gabi Lorenzo (glorenzo16@georgefox.edu).

General 3D Printing Knowledge

3D printing is the process of joining material together to create a three-dimensional object using computer control. It is a form of additive manufacturing. Objects are created using a 3D model. There are many different types of 3D printing, and the Prototype Lab utilizes two types which are FDM (fused deposit modeling) and SLA (stereolithography).

In the Prototype Lab, objects are most commonly printed from an STL file. This means if you create a part in Solidworks that you must save the file as a STL instead of a SLDPRT. Once the file is in STL form, it can then be processed by a slicer software. The slicer software converts the 3D model into thin layers and produces a G-code file. G-codes communicate with the chosen 3D printer, giving it directions on how to print the object.

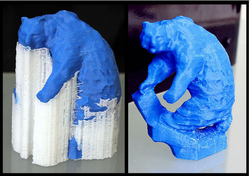

Different 3D printers will run with different slicer programs. Typically a program will allow you to edit various parts of the process. One common consideration will be that of the layer thickness. This is the resolution at which the printer will print at. Each printer will have its own range of resolution. The thinner the layer thickness (higher resolution), the more detail you will get, but the print will be created more slowly. The thicker the layers (lower resolution), the less detail you will receive, but the object will be printed more quickly. Another consideration is support. For objects with overhangs, holes, etc., support will be needed. This will give the printer a surface to print on so that it can continue to build the print layer by layer. Each printer uses supports differently. Some printers have break away support while other have dissolvable support material.

Common errors... adhesion, clogging, air extruding... watch for first 30 min... stringing

General Laser Cutting Knowledge

Equipment Overview

| Name | Company | Model |

|---|---|---|

| Dissolvable Support Bath | Support Cleaning Apparatus | 1200HT |

| Formlabs 3D Printer | Formlabs | Form 3 |

| Markforged 3D Printer | Markforged | Mark II |

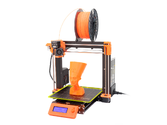

| Prusa 3D Printer | Prusa | MK4 / MK4S |

| Prusa XL | Prusa | XL |

| Speedy 300 | Trotec | Speedy 300 |

| Speedy 400 | Trotec | Speedy 400 |

| Equipment | Icon | Image |

|---|---|---|

| Dissolvable Support Bath | ||

| Formlabs 3D Printer | [[|center|x125px|link=Formlabs 3D Printer]] | |

| Markforged 3D Printer | ||

| Prusa 3D Printer | ||

| Prusa XL | ||

| Speedy 300 | ||

| Speedy 400 |

3 commandments

1. Safety First

Safety First is the rule we hold highest of the 3. Given the delicate nature of our machines, and the different chemicals and materials we use in the Prototype lab, this rule applies to both the safety of you, and the machines.

Keeping yourself safe in the Prototype Lab is very easy, as there are very few ways to hurt yourself or the machines. However, proper procedure must be followed at all times