Foam Cutter

Make: Proxxon

Model: Thermocut 12E & 115E

Ace: Needed (Makerhub@georgefox.edu).

Location: The Hub

Description

The PROXXON THERMOCUT allows you to cut polystyrene (Styrofoam) in a clean and safe way without frayed edges or particulation. This foam cutter is deal for architects, designers, decorators, artists, and teachers. Examples include building architectural models, classic model railroads, plane and boat items, and numerous decorative items.

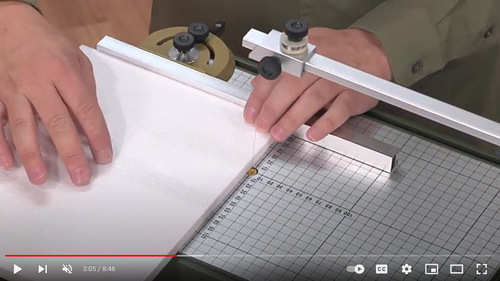

The large table with 15 11/32" x 11" (390 x 280mm) ensures smooth and easy movement of the workpiece. The printed grid and protractor assist with division and cutting. The solid aluminum overarm has a 13 3/4" (350mm) throat and offers 5 1/2" (140mm) in height. The holder and wire coil (one spool of wire 98ft., 0.008" diameter is included) may be shifted and adjusted along the overarm to enable miter cutting. An LED indicates operation and thus reminds you not to touch the hot wire to prevent burnt fingers (the wire heats to maximum in less than 1 second).

Note: The correct temperature, being material and thickness dependent, is learned from experience. Profiles are ideally cut at lower temperatures and while applying less cutting force.

Technical data:

Cutting wire temperature: 210 - 390 °F (100 - 200 °C) Transformer secondary max: 10V at 1.0A Volts: 110 - 120V AC, 60 Hz Weight: 6.6 lb (3kg)

Here is an example of the table in use. (Link takes you to YouTube - embedding not allowed for this video??)

This is Proxxon's video for the hand-held cutter.

This is Proxxon's video for the table-top cutter.

Documentation

Terminology

There are two types of polystyrene foam best suited for processing with the Hot wire foam cutters and Hot knife cutters: extruded polystyrene (XPS foam), and expanded polystyrene (EPS foam). Although both types of insulation are comprised of polystyrene, the two types of manufacturing processes produce finished products with very different performance properties. XPS is manufactured in a continuous extrusion process that produces a homogeneous closed cell cross-section, whereas EPS is manufactured by expanding spherical beads in a mold, using heat and pressure to fuse the beads together.

User Manual

Training

Operation

A 0.2mm wire is heated using a safe 10V source, and this heated wire cuts through the polystyrene, melting it and providing a clean cut. By varying the amount of voltage on the wire (and thus current), the wire temperature can be varied between 100℃ - 200℃ (212℉ - 392℉).

Demonstration

Insert text

General Procedure

Insert text

Safety

Insert text

Certification

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |