Difference between revisions of "Rework Station"

| Line 39: | Line 39: | ||

====Overview==== | ====Overview==== | ||

| − | + | The Rework Station is essential for fixing what you messed up during the fabrication process. Consisting of an Air Bath, Air Pencil, and Air Pick, the Rework Station allows you heat up a specific area of the PCB and make modifications, whether that means adding/removing some solder on the pads, rotating a component, or completely replacing a component. Other tools are available for similar purposes, such as a desoldering gun, and an additional heat gun for larger components. | |

====Demonstration==== | ====Demonstration==== | ||

| − | To show a complete knowledge of the Air Bath, Air Pencil, Air Pick, Desoldering Gun, and Heat Gun, the student will have a PCB prepared and perform tasks with the station as a whole. Using the Air Bath, Air Pencil, and Air Pick, students will | + | To show a complete knowledge of the Air Bath, Air Pencil, Air Pick, Desoldering Gun, and Heat Gun, the student will have a PCB prepared and perform tasks with the station as a whole. Using the Air Bath, Air Pencil, and Air Pick, students will remove a SMD and solder it back on. Using the Desoldering Gun, students will remove a soldered through hole component. Using the Heat Gun, students will mount a larger SMD, solder it on, and then remove it. |

====General Procedure==== | ====General Procedure==== | ||

| − | + | # Moving/Replacing Components | |

| − | + | ## | |

| + | # Desoldering Through Hole Components | ||

==Safety== | ==Safety== | ||

Revision as of 13:30, 13 June 2019

ZT-2, ZT-3, ZT-1-CLS-DPU, Hakko FR-301, Quick861DW

Make: Zephyrtronics

Model: ZT-2, ZT-3, ZT-1-CLS-DPU, Hakko FR-301, Quick861DW

Ace: Needed (Makerhub@georgefox.edu).

Location: PCB Lab

Description

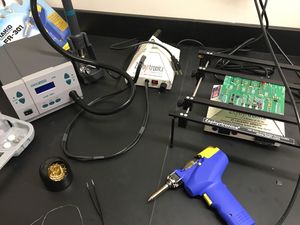

The Rework Station is essential for fixing what you messed up during the fabrication process. Consisting of an Air Bath, Air Pencil, and Air Pick, the Rework Station allows you heat up a specific area of the PCB and make modifications, whether that means adding/removing some solder on the pads, rotating a component, or completely replacing a component. Other tools are available for similar purposes, such as a desoldering gun, and an additional heat gun for larger components.

Documentation

Terminology

User Manual

Training

Overview

The Rework Station is essential for fixing what you messed up during the fabrication process. Consisting of an Air Bath, Air Pencil, and Air Pick, the Rework Station allows you heat up a specific area of the PCB and make modifications, whether that means adding/removing some solder on the pads, rotating a component, or completely replacing a component. Other tools are available for similar purposes, such as a desoldering gun, and an additional heat gun for larger components.

Demonstration

To show a complete knowledge of the Air Bath, Air Pencil, Air Pick, Desoldering Gun, and Heat Gun, the student will have a PCB prepared and perform tasks with the station as a whole. Using the Air Bath, Air Pencil, and Air Pick, students will remove a SMD and solder it back on. Using the Desoldering Gun, students will remove a soldered through hole component. Using the Heat Gun, students will mount a larger SMD, solder it on, and then remove it.

General Procedure

- Moving/Replacing Components

- Desoldering Through Hole Components

Safety

Insert text

Certification

Foxtale Quiz

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |

The current Ace of the Rework Station is Needed (Makerhub@georgefox.edu).

What is the Rework Station?

The rework station is a collection of tools used for heating up printed circuit boards to remove surface mount components or touch up soldering jobs. The tools vary from a board heater, to very precise pin-point heating tools.

Documentation

Training

- Getting Started CHANGE

- HelpDocs CHANGE

Terminology

PCB - Printed Circuit Board

SMD - Surface Mount Device

SMT - Surface Mount Technology

Heat Gun- A soldering iron-like tool that blows out hot air through a variable sized hole (often variable through interchangeable tips).

Helping Hands - A tool that grabs onto your PCB with little clips.

Soldering - The process of melting a tin-lead compound of metal to secure pins and leads of electronic components onto the terminals of a printed circuit board.