Difference between revisions of "Injection Molding Machine"

| Line 11: | Line 11: | ||

|Has certification= | |Has certification= | ||

|Has make=LNS Technologies | |Has make=LNS Technologies | ||

| − | |Has model=150A | + | |Has model=150A |

|Has ace=Samuel Reimer;sreimer18@georgefox.edu | |Has ace=Samuel Reimer;sreimer18@georgefox.edu | ||

}} | }} | ||

| Line 45: | Line 45: | ||

Gate - The thin section connecting a runner or sprue to the part cavity | Gate - The thin section connecting a runner or sprue to the part cavity | ||

| + | [[File:...injectionMolderTerms.png|none|thumb|469x469px]] | ||

User Manual | User Manual | ||

Revision as of 12:43, 16 July 2019

Make: Pim-shooter

Model: 150A

Ace: Sam Manina (smanina22@georgefox.edu).

Location: The Vault

Description

The Model 150A PIM-SHOOTER™by LNS Technologies is a bench model injection molder designed for production of thermoplastic parts in quantities required for making prototypes and low-volume production (or higher-volume production of small parts). Due to the machine’s small size it is limited to producing small parts, but it is capable of producing these parts efficiently, accurately (as accurate as the mold is), and repeatedly.

Documentation

Terminology

Flash - This is when the two halves of a molding tool are not properly sealed, causing molten plastic to leak out of the part cavity

Sprue - The main channel guiding the molten plastic from the nozzle of the injection molder into the part cavity.

Runners - Subchannels that branch off from the sprue and into the part cavities. These are used for mold tools that contain multiple part cavities.

Gate - The thin section connecting a runner or sprue to the part cavity

User Manual

Training

Overview

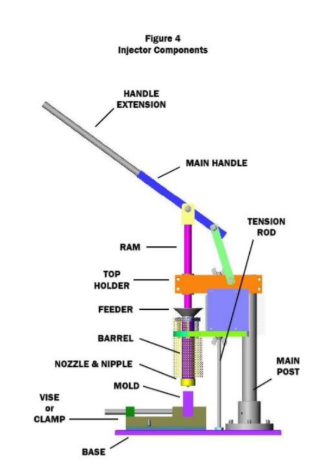

The injection molder works by melting plastic pellets within a heated barrel to a specific temperature, and using a ram plunger to force the molten plastic through a nozzle, into a mold cavity.

Demonstration

For the injection molder demonstration, a pre-existing mold will be provided and the person must successfully injection mold the part. They should demonstrate proper adjustment of height to fit the mold, setting up for injection (filling the hopper, setting the temperature, and aligning the mold under the nozzle), injecting, and removal of the mold and part from the mold.

General Procedure

- Setup

Safety

Insert text

Certification

Foxtale Quiz

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |