Difference between revisions of "Hand Router"

| (40 intermediate revisions by 4 users not shown) | |||

| Line 4: | Line 4: | ||

|Is used in domain=Wood | |Is used in domain=Wood | ||

|Has name={{PAGENAME}} | |Has name={{PAGENAME}} | ||

| + | |Has make=Porter Cable | ||

| + | |Has model=8902 | ||

| + | |Has serial number=937113201832-49 | ||

| + | |Has life expectancy= | ||

| + | |Has year of manufacture or purchase= | ||

| + | |Has replacement cost= | ||

|Has icon=File:Hand Router.png | |Has icon=File:Hand Router.png | ||

|Has icondesc= | |Has icondesc= | ||

| Line 10: | Line 16: | ||

|Has imagedesc=Porter Cable Model 8902 2.25 HP Hand Router. | |Has imagedesc=Porter Cable Model 8902 2.25 HP Hand Router. | ||

|Has description=Hand router for use in the Maker Hub when routing wood if you intend to use a template, route imprecisely, or are too old-school to use the handheld CNC router. | |Has description=Hand router for use in the Maker Hub when routing wood if you intend to use a template, route imprecisely, or are too old-school to use the handheld CNC router. | ||

| − | |Has certification= | + | |Has certification=https://georgefox.instructure.com/courses/1269 |

| − | + | |Has ace=Needed;Makerhub@georgefox.edu | |

| − | |||

| − | |Has ace= | ||

}} | }} | ||

| − | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}| | + | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|140px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]] |

[[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|300px|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]] | [[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|300px|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]] | ||

| Line 21: | Line 25: | ||

Model: {{#show: {{PAGENAME}} |?Has model}} | Model: {{#show: {{PAGENAME}} |?Has model}} | ||

| + | |||

| + | Serial Number: {{#show: {{PAGENAME}} |?Has serial number}} | ||

Ace: {{#show: {{PAGENAME}} |?Has ace.Has name}} ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). | Ace: {{#show: {{PAGENAME}} |?Has ace.Has name}} ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). | ||

Location: {{#show: {{PAGENAME}} |?Is located in facility}} | Location: {{#show: {{PAGENAME}} |?Is located in facility}} | ||

| + | |||

==Description== | ==Description== | ||

| Line 30: | Line 37: | ||

The hand router is very versatile but can also be a very dangerous tool if not used properly. Used in conjunction with the proper jigs and templates, the router can accomplish a wide variety of tasks with relative ease. Holes and channels of varying depths and nearly limitless shapes can be cut. The router can also use special bits to cut bevels and chamfers along the edges of a workpiece. | The hand router is very versatile but can also be a very dangerous tool if not used properly. Used in conjunction with the proper jigs and templates, the router can accomplish a wide variety of tasks with relative ease. Holes and channels of varying depths and nearly limitless shapes can be cut. The router can also use special bits to cut bevels and chamfers along the edges of a workpiece. | ||

| − | Introductory Video | + | Introductory Video |

{{#evu:https://www.youtube.com/watch?v=8Vl8Jbw3cSk}} | {{#evu:https://www.youtube.com/watch?v=8Vl8Jbw3cSk}} | ||

| − | |||

| − | About Direction of Cut | + | Another Introductory Video |

| + | {{#evu:https://www.youtube.com/watch?v=bG2ldmVt56Y}} | ||

| + | |||

| + | About Direction of Cut | ||

{{#evu:https://www.youtube.com/watch?v=5Qqimqo-ohU}} | {{#evu:https://www.youtube.com/watch?v=5Qqimqo-ohU}} | ||

==Documentation== | ==Documentation== | ||

| − | [[: | + | [[Media:HandRouterManual890_series.pdf|Hand Router User Manual]] |

====Terminology==== | ====Terminology==== | ||

| + | Each bit is made for a different job. The wood shop has a wide assortment, although less common types may be unavailable. It should be noted that different bit sizes and profiles will operate better at different speeds. The amount of material that is being removed in each pass as well as the hardness of the wood should determine the speed the router is ran. You should not attempt to use any bits over 1" in diameter as these are designed for use in a router table and could create a dangerous situation. | ||

| − | + | Occasionally routing can leave burn marks on the work piece. This usually means that the bit in the router has become dull, let a shop supervisor know if a bit seems dull. Sometimes the burning is due to build up of resin and other gunk (a technical term) on the back of the blade insulating the bit and allowing for heat to build up, make sure to keep bits clean. A final possible cause of burning wood while routing is taking passes that are too slow or setting the router bit speed too high. A good rule of thumb for setting router bit speed is the larger the cutter the slower the speed. Set the spindle speed adjustment to around 20000 RPM when starting out and you can adjust as needed. If a specific cutter is marked with a recommended speed start with that. | |

| − | |||

| − | Occasionally routing can leave burn marks on the | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | [[File:Hand router.jpg|500px|right]] | ||

| + | <figure-inline>[[Image:RouterBits.jpg|331x331px]]</figure-inline> | ||

| + | *Fixture - Tooling you make or buy, which assists in the usage of a tool and helps yield a higher quality product. | ||

| + | *Soft Start - Electronic circuit used to slow the start up speed of a motor or power tool. | ||

| + | ====Operation==== | ||

| + | The hand router is a versatile power tool and can accommodate 2 different cutter shank diameters. Both the 1/4" and 1/2" shank require their own specific collet. The collet is changed by unscrewing the collet clamping nut and removing the collet. The collet is located near the cutter so it tends to collect a large amount of wood dust. It's important to always clean out the collet and collet housing so the spring clamping action works properly. It's very important to have the proper amount of cutter shank engagement. A cutter shank that is not installed correctly could come loose or even damage the collet. You should have at least 3/4" engagement into the collet. The cutter should be inserted all the way into the collet then pulled out approximately 1/8". This will make sure the shank is not bottomed out. | ||

| + | If your material looks good, the next step is to set up the router itself. When setting up the router height, | ||

| − | + | After the router is set up you are ready to cut. Turn on the router and slowly feed the cutter into the material, making sure to keep your hands on the handles. Do not stop the cutter in one spot and let it sit as this will cause burning. Also make sure the router spindle has stopped spinning before taking your hands off the handles. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

====Demonstration==== | ====Demonstration==== | ||

| Line 104: | Line 99: | ||

10. Only handle the router with both hands on the handles. Move the router onto your material. Make sure the cutter does NOT make contact. | 10. Only handle the router with both hands on the handles. Move the router onto your material. Make sure the cutter does NOT make contact. | ||

| − | 11. Turn on the power switch and let the router get up to speed. Slowly feed the cutter into the material until the bearing makes contact with the material edge. Keep the guide plate flat on your material and slowly feed the router along | + | 11. Turn on the power switch and let the router get up to speed. Slowly feed the cutter into the material until the bearing makes contact with the material edge. Keep the guide plate flat on your material and slowly feed the router opposite the direction of the spinning cutter. If you travel in the wrong direction the cutter will try to pull the router along. If you travel too slow the wood will start to burn. Traveling too fast will produce a poor cut. Be careful to keep the router from tilting when traveling along the edge and especially while traveling around a corner. |

12. Power off the router after making your cut. Let the spindle stop turning before moving the router away from the work piece. | 12. Power off the router after making your cut. Let the spindle stop turning before moving the router away from the work piece. | ||

| Line 115: | Line 110: | ||

==Safety== | ==Safety== | ||

| + | *Be aware of the cutter location on a router at all times as it is fairly exposed. | ||

| + | *Keep all body parts away from the cutter and make sure the motor has stopped before removing your hands from the handles. | ||

| + | *Any equipment/tool that you don't handle safely is the most dangerous tool in the shop. | ||

| + | *Don't attempt to use any router bits exceeding 1" in diameter. | ||

| + | *Never attempt to use the router without the base. | ||

{{#evu:https://www.youtube.com/watch?v=Ble_8zw_C9w}} | {{#evu:https://www.youtube.com/watch?v=Ble_8zw_C9w}} | ||

==Certification== | ==Certification== | ||

| − | + | Complete the <strong>Wood Shop - {{PAGENAME}} Module</strong> at the link below to gain access to the {{PAGENAME}}. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email <span style="color:blue">makerhub@georgefox.edu</span> if you have any questions. | |

| + | |||

| + | [https://georgefox.instructure.com/enroll/G7CTPX Maker Hub Canvas Course] | ||

==Troubleshooting== | ==Troubleshooting== | ||

| − | If you notice burning on the material it could be caused by feeding the cutter at too slow of a rate. A dull cutter can also cause material burning. | + | If you notice burning or dark coloration on the material it could be caused by feeding the cutter at too slow of a rate. A dull cutter can also cause material burning. |

==Maintenance== | ==Maintenance== | ||

Revision as of 00:26, 26 August 2023

Make: Porter Cable

Model: 8902

Serial Number: 937113201832-49

Ace: Needed (Makerhub@georgefox.edu).

Location: Wood Shop

Description

The hand router is very versatile but can also be a very dangerous tool if not used properly. Used in conjunction with the proper jigs and templates, the router can accomplish a wide variety of tasks with relative ease. Holes and channels of varying depths and nearly limitless shapes can be cut. The router can also use special bits to cut bevels and chamfers along the edges of a workpiece.

Introductory Video

Another Introductory Video

About Direction of Cut

Documentation

Terminology

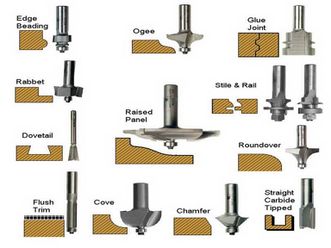

Each bit is made for a different job. The wood shop has a wide assortment, although less common types may be unavailable. It should be noted that different bit sizes and profiles will operate better at different speeds. The amount of material that is being removed in each pass as well as the hardness of the wood should determine the speed the router is ran. You should not attempt to use any bits over 1" in diameter as these are designed for use in a router table and could create a dangerous situation.

Occasionally routing can leave burn marks on the work piece. This usually means that the bit in the router has become dull, let a shop supervisor know if a bit seems dull. Sometimes the burning is due to build up of resin and other gunk (a technical term) on the back of the blade insulating the bit and allowing for heat to build up, make sure to keep bits clean. A final possible cause of burning wood while routing is taking passes that are too slow or setting the router bit speed too high. A good rule of thumb for setting router bit speed is the larger the cutter the slower the speed. Set the spindle speed adjustment to around 20000 RPM when starting out and you can adjust as needed. If a specific cutter is marked with a recommended speed start with that.

<figure-inline> </figure-inline>

</figure-inline>

- Fixture - Tooling you make or buy, which assists in the usage of a tool and helps yield a higher quality product.

- Soft Start - Electronic circuit used to slow the start up speed of a motor or power tool.

Operation

The hand router is a versatile power tool and can accommodate 2 different cutter shank diameters. Both the 1/4" and 1/2" shank require their own specific collet. The collet is changed by unscrewing the collet clamping nut and removing the collet. The collet is located near the cutter so it tends to collect a large amount of wood dust. It's important to always clean out the collet and collet housing so the spring clamping action works properly. It's very important to have the proper amount of cutter shank engagement. A cutter shank that is not installed correctly could come loose or even damage the collet. You should have at least 3/4" engagement into the collet. The cutter should be inserted all the way into the collet then pulled out approximately 1/8". This will make sure the shank is not bottomed out.

If your material looks good, the next step is to set up the router itself. When setting up the router height,

After the router is set up you are ready to cut. Turn on the router and slowly feed the cutter into the material, making sure to keep your hands on the handles. Do not stop the cutter in one spot and let it sit as this will cause burning. Also make sure the router spindle has stopped spinning before taking your hands off the handles.

Demonstration

Demonstrate you can safely setup the hand router/tooling. You will need to chamfer or round over an edge of material. Remember to always unplug the router when changing tools or making adjustments to prevent an accidental turn on situation. The direction of travel is also important when making cuts to prevent tearing out corners and edges. Use router bits with bearings to help guide the cutter. Never attempt to free hand a cut without a guide for the router to follow as this can lead to the router running away out of control.

General Procedure

Edge Chamfer

1. The material you are cutting needs to be free from nails or foreign objects. The material should be at least 1/2" thick.

2. Make sure the material is secured. You can use clamps, double sided tape, or bench pucks. Material that is not secure will move and create a hazard.

3. Select the type of router bit you wish to use. Make sure the bit has a bearing guide.

4. Verify the router is unplugged and place the router upside down on the bench.

5. Select the 1/2" or 1/4" collet needed for the appropriate bit.

6. Install the router bit into the collet at least 3/4" Always make sure the collet is clean before inserting a bit to prevent poor clamping issue.

7. Firmly lock the tool down using the router wrench. The nut will squeeze the collet down onto the router bit shank. You will need to use the spindle nut wrench and the spindle lock button.

8. Position the router onto your material. Loosen the spindle depth lock. Adjust the height of cutter engagement as desired and lock the spindle depth lock.

9. Make sure the power switch is in the OFF position. Verify the router cutter is clear and place the router on its side. Proceed to plug in the router.

10. Only handle the router with both hands on the handles. Move the router onto your material. Make sure the cutter does NOT make contact.

11. Turn on the power switch and let the router get up to speed. Slowly feed the cutter into the material until the bearing makes contact with the material edge. Keep the guide plate flat on your material and slowly feed the router opposite the direction of the spinning cutter. If you travel in the wrong direction the cutter will try to pull the router along. If you travel too slow the wood will start to burn. Traveling too fast will produce a poor cut. Be careful to keep the router from tilting when traveling along the edge and especially while traveling around a corner.

12. Power off the router after making your cut. Let the spindle stop turning before moving the router away from the work piece.

13. Place the router on its side and unplug the router to prevent an accidental power on condition.

14. Remove the router bit by using the wrench and spindle lock button.

15. Reset the space.

Safety

- Be aware of the cutter location on a router at all times as it is fairly exposed.

- Keep all body parts away from the cutter and make sure the motor has stopped before removing your hands from the handles.

- Any equipment/tool that you don't handle safely is the most dangerous tool in the shop.

- Don't attempt to use any router bits exceeding 1" in diameter.

- Never attempt to use the router without the base.

Certification

Complete the Wood Shop - Hand Router Module at the link below to gain access to the Hand Router. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email makerhub@georgefox.edu if you have any questions.

Troubleshooting

If you notice burning or dark coloration on the material it could be caused by feeding the cutter at too slow of a rate. A dull cutter can also cause material burning.

Maintenance

General maintenance

- Make sure cutter bits are clean.

- Remove and clean the collets as needed.

- Make sure any adjustment screws are tight.

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |