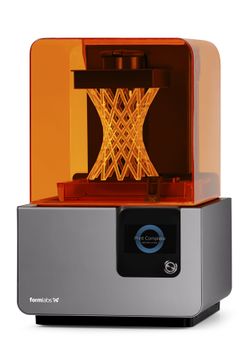

Formlabs 3D Printer

The Form 2 is Formlab's 3rd generation printer boasting a whole range of new features including a new peeling mechanism, heated tank, touchscreen display, wireless controls and an automated resin system. The resulting prints that come off of the Form 2 have consistently been among the highest quality objects to come off of any desktop 3D printer. This machine is best used with the Form Wash and Cure [1]

Documentation

Training

SLA Printing

- The Form 2 employs SLA Printing.

Changing Resin

- Remove, clean, and replace the build plate.

- The build plate is the large metallic square-shaped block the Form 2 builds onto, held in place at the top of the printer.

- Pull lever holding build plate in place up, allowing the build plate to be removed

- Place the build plate on the holding rack in the Form Wash. Run the build plate through the Wash to remove resin. For the build plate, the Wash should be set to 10 minutes.

- Let the build plate air dry before replacing, secure by flipping lever down.

- Remove and replace the resin tank and wiper.

- The resin tank is the translucent, orange, plastic box filled with resin.

- The wiper is the black rod which lays flat in the resin tank and hooks over one edge.

- Firmly pull wiper back until it's out of the slot and loose in the resin tank. Leave the wiper in the resin tank, each tank has its own wiper.

- Firmly pull tank back until it pops loose of the printer, put the appropriate lid on the resin tank, and store with wiper in tank. Be sure to wipe up any resin that spills during the removal process.

- Before inserting the new resin tank, remove its lid and store.

- Slot the new resin tank into place in the printer.

- Slot the new tank's wiper into place.

- Firmly pull wiper back until it's out of its slot and loose in the resin tank. Leave the wiper in the resin tank, each tank has its own wiper.

- Firmly pull tank back until it pops loose of the printer, put the appropriate lid on the resin tank, and store with wiper in tank. Be sure to wipe up any resin that spills during the removal process.

- Close lid of resin cartridge in back of printer, remove, and store.

- Slot in the new resin cartridge, tank, and wiper of the desired resin.

- Use a scraping tool to dredge bottom of new resin tank for any hardened resin or loose bits of material, remove any found bits.

Maintenance

- Every few prints the resin tank should be dredged with a scraping tool to search for any hardened resin or loose bits of material, and when resin tanks are switched out. Remove any found bits.

Resources

Link to shop Equipment page

Common errors, how to fix

More in depth to resin changing

Why choose form printer/ why choose resin type

Pictures-saved in Form 2 Wiki Pics

Remove material from failed prints, how to remove completed prints-scraping, using stand