Mug Press

Make: Heat Press Nation

Model: HPN-SIG-MUG

Serial Number: HPN-SIG-MUGWHB260USJL-3-009

Ace: Needed (makerhub@georgefox.edu).

Location: The Hub

Description

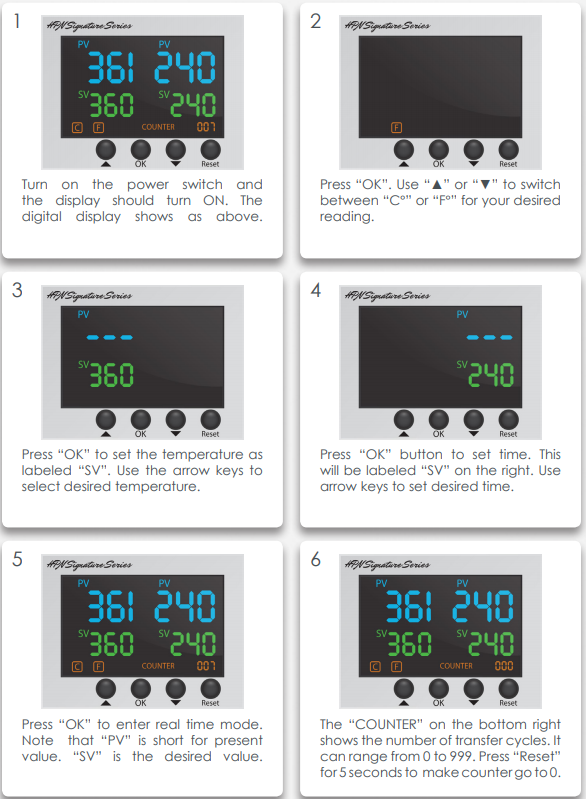

The HPN Signature Series Mug Cup Heat Press machine is a professional grade mug press designed to easily and efficiently heat transfer custom images onto almost any size and shape of mug. From small sized graphics such as names and logos to full wrap, edge to edge images. This machine is to be used with transfers from the sub dye printer. When transferring an image to a mug you need to make sure the material used is compatible. Mugs used with the sub dye process have a special coating. Here is an example of transferring an image:

Documentation

Terminology

- SV - Stands for set value and is used to indicate the parameters that the press should be operating at.

- CV - Stands for present value and indicates the current value of the heat press parameters.

User Manual

Training

Operation

The operation of the mug press is pretty simple. First, select a heating element that fits your glass or mug and fasten it into place using the black screws. There is no formula for selecting the correct element other than putting your mug inside and making sure it fits snug. Adjust the pressure using the large black knobs so that there is a firm, even pressure over the mug. Next, set the time and temperature. Feel free to experiment with different values as there is not an exact formula, but for dye sublimation set the temperature around 385°F for 190 seconds. The paper should have light tan look after removing it from the press. If the paper appears burnt the temperature should be decreased. After the time and temperature are set place the mug in the element and clamp down. The timer will beep once the transfer is complete. For complete details see the general procedure.

Demonstration

A mug or glass is required in order to perform a transfer on this machine which makes it difficult to perform simple test or demonstration transfers. Consequently, the demonstration will be pressing a graphic of choice onto a mug or glass.

General Procedure

- Select a heating element. Heating elements come in different sizes with their own connection cord. This is not an exact science, simply slide the mug into the element and make sure it can wrap around it with a snug fit.

- Use the black set screws to secure the heating element into the press and plug it into the controller. Make sure to screw in the plug as well to ensure a good connection.

- Once the heating element is installed you will want to adjust the pressure applied to the mug using the four large pressure adjustment knobs. The pressure should be evenly distributed across the mugs's surface and firm without risk of crushing it.

- Adjust the time and temperature. 385 °F for 190 seconds is recommended as a starting point but feel free to try new things to improve the results. See the image below for details on changing the time and temp.

- Place the graphic onto the mug. High temp tape should be used so that the graphic does not shift after it is placed into the press.

- Put the mug into the press and clamp down until the timer beeps.

- Remove the mug from the press and wait about 30 seconds + before removing the paper. The mug will be very hot.

- Reset the space by turning off the machine, throwing away any scraps and wiping any debris off the machine.

Safety

- This machine uses heat to operate so be aware of the heating element when it is running to avoid burns.

- Do not leave the heating element on any longer than necessary if there is nothing inside it. Long periods of time without something in the press can damage the heating element.

Certification

Troubleshooting

- If the paper looks really dark/black on removal the temperature needs to be reduced.

Maintenance

General maintenance

The only maintenance needed on this machine is general cleaning. Use a paper towel and cleaner if necessary to wipe of any dust and vinyl debris.

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| General Cleaning | As needed | Student |