Heavy Duty Sewing Machine

Make: Consew

Model: 206RB

Serial Number:

Ace: Dan Schutter (text him at 503-317-5614) ().

Location: The Hub

Safety First

Here are some safety instructions for the Heavy Duty Sewing Machine. Remember... SAFETY FIRST!!!

- Fire / Burns – the propane torch emits an extremely hot open flame that can cause serious burns. Do not point the torch towards yourself or anyone else. Do not touch the nozzle or put your hands in front of the nozzle. Do not tip the torch sideways when annealing. Always make sure to close the valve and lock the trigger after you finish annealing. Be mindful that the needle nose pliers can be hot too after annealing. If you get burned, run cold water over the burned area for several minutes to reduce inflammation and the potential for blistering.

- Eye Injury – you must wear safety glasses throughout the annealing process and when swinging a hammer to punch out the center of a coin. Anyone else within a 6-foot radius should also wear safety glasses when you are annealing or hammering.

- Crush Hazard – exercise caution when using the press to fold your coin or using the stretcher/reducer. These tools have several pinch points and can cause serious injury to your hand if it gets caught between the moving parts.

- Sharp Hazard – coins can have sharp burrs after punching a hole. Use the manual deburring tool to remove the sharp edge.

- Corrosive Chemicals – the Midas Black Max finish contains hydrochloric acid which can cause severe skin burns and eye damage. A lab coat, chemical goggles, and gloves must be worn when handling hydrochloric acid. Consult the Maker Hub staff for proper disposal. Midas Black Max finish should only be applied to real silver/gold coins. All finishes must be applied in the Finishing Room to minimize your exposure to harmful vapors.

- When punching out the center of a coin, place a wooden block on the floor with the punch assembly on top of it to protect the end of the punch from being damaged by the concrete.

- Ensure there is water in the pot before attempting to anneal your coin.

- Don’t get a coin ring stuck on your finger.

Description

Things to know in order to succeed on the Consew should include:

· Questions on the safety protocol (eye protection?)--yes!

· The difference between the servo and clutch motors; maybe the advantages of the servo over the clutch motor, so folks appreciate the greater ease and safety. (From the video I found; see below. Nick has this video for preview.)

· Questions on the sections of the uploaded, reformatted, and corrected (mostly spelling, grammar, and formatting errors) operating manual which are pertinent to the demo. (Nick, I have specific suggestions for formatting the manual that I think I should submit to you in a separate document.)

· Anatomy of the machine making certain they can identify everything they need to get through the safety protocol.

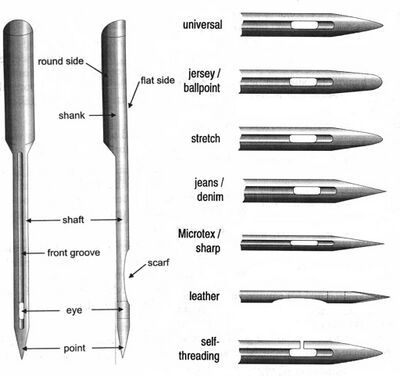

· The anatomy of a needle, so they insert it facing the correct direction—scarf to the right.

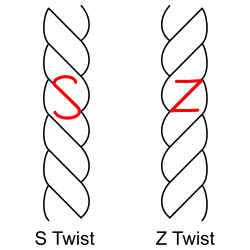

· Question proving they know the difference between S- and Z-twist in thread and how that relates to proper threading of the machine. Attach the diagram, or insert a link to the diagram. (Because if they use thread with the wrong twist for the needle, the machine will jam up.)

· Question regarding the stitching speed range: 350 sts/min. to 3450 sts/min.

· Question regarding the thread controller spring, because they’ll need to make that adjustment themselves and should know what it is, where it is, and how to do that.

RE: Safety protocol

· Eye protection

· Removing and replacing the needle. Needs to be part of the training/demo.

· Every time you change the needle make sure it is still aligned over the needle hole by turning the flywheel one complete rotation toward you. If the needle does not pass cleanly through the needle hole, tell Justin. Do not sew!

· If the machine is skipping stitches it needs a timing adjustment; don’t sew—tell Justin.

· Irregular stitch length or overheating; don’t sew—tell Justin.

· Make sure the bobbin case is empty before trying to fill another bobbin. If there is a bobbin left in the bobbin case when winding a new bobbin a thread jam will occur in the bobbin case. Congratulations! You just broke it!

RE: Changing the needle

It’s easy to do, but will you want the students to seek the help of the ace or a tech?

I verified a screwdriver key, such as the ones purchased for the Janomes, will work for loosening the screw holding the needle in place. One has been added to the notions drawer in the worktable for the Consew.

RE: Demo and instructions for it, (These things need to included.)

· Following the safety protocol.

· Threading the machine

· Filling the bobbin, because people are going to need thread to match their project.

· We need a demo project or projects to choose from. Leather or upholstery?

· They should have to prove they can remove and replace the needle. This is where they need to know what the scarf is and which direction it should face.

· Double checking the stitch speed and stitch length, and that they know how to change those settings.

· Adjusting thread controller spring is simple and should be known and demonstrated since its function is dependent on the materials being used.

· In the instruction for the demo students should be encouraged to do test samples before stitching on their actual project.

· I think for the most inexperienced it would be helpful to remind them ‘righty-tight/lefty-loosey re: the tension knob.

· Stitch length dial works differently than the instruction book says; there is no stopper.

· Part of reformatting the uploaded/downloaded instruction manual should be marking which adjustments listed in the contents should only be performed by the tech. (Or maybe those parts of the manual shouldn’t be on the WIKI at all, in order to avoid confusion.)

General remarks:

Do we need a toolkit especially for the Consew? Something like the sewing kits that we have for the Janomes. One that has upholstery sewing needles, etc. . . . We don’t really have any instructions for how to sew with an industrial, not even in the manual. Things like checking for your thread tails to make sure they're behind the work and won't become entangled in the stitching. Or where your hands should be while stitching. Or what landmarks on the machine to use to find and guide your stitch path. Where you should be sitting The end result of following the instructions on the WIKI will be the ability to operate the machine safely, not the ability to succeed at making anything on it.

The Videos:

https://makernexuswiki.com/wiki/Consew_206RB-4_Walking_Foot_Industrial_Sewing_Machine This is the wiki for some folks who have a very similar machine. Most of their links look good, but should be viewed before being adopted--just to be sure they're relevant. The text is very good--terms and directions are clear and correct; I'd imitate that as much as possible.

https://en.wikipedia.org/wiki/Sewing_machine_needle--The scarf of the needle is referred to in the directions for changing the needle in the operating instructions manual for the machine.

https://www.superiorthreads.com/education/thread-twist-explained--'S' and 'Z' twists are very clearly explained. On the Consew you must use 'left twisted thread for upper/needle thread, but you can use either right or left twisted thread for lower/bobbin thread.' According to the folks at Superior the terms left and right twist are not correct terminology. They have a video embedded in the article that explains everything. The Consew needs Z-twist for the needle; Z-twist is the same as left twist. It might be nice to have a loupe among our tools, so students can check this before they thread the machine.

https://www.youtube.com/watch?v=lavkvsU5ltk (Helps explain the difference between the machine as it was originally powered--by a clutch motor, and as it is powered now--with a servo motor. Should offer some reassurance to newbies that they will be able to operate the Consew safely. Also, helps explain why parts of our manual aren't relevant.)

Let me know if you'd like me to find any other instructional materials.

The wiki page for the heavy duty sewing machine is coming soon. This is a place holder for the future.

Here is an example of this piece of equipment being used.

Here is an example of this piece of equipment being used.

Documentation

Terminology

- Bobbin: The metal drum that holds the lower thread.

- Foot:

On the Consew you must use left twisted thread for upper/needle thread, but you can use either right or left twisted thread for lower/bobbin thread.

User Manual

Training

Operation

Make sure the dots on the handwheel and frame are aligned before removing or inserting a bobbin.

Demonstration

Insert text

General Procedure

Insert text

Safety

Make sure the power switch is off before threading the machine or doing anything other than sewing. Leave any other maintenance to the ACE or technician. Keep fingers out of the needle path. This machine can sew though thick material at a rapid pace. Always remove the bobbin from the machine before using the winding mechanism.

Certification

Canvas Quiz

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Oil Machine Locations | As Needed | Tech |