Horizontal Bandsaw

Make: Ellis Mfg. Company Inc.

Model: 1600

Serial Number: 161310903

Ace: Needed (Makerhub@georgefox.edu).

Location: Machine Shop

Safety First

Here are some safety instructions for the Horizontal Bandsaw. Remember... SAFETY FIRST!!!

- Never place your hand below the blade. If, for some reason, the blade were to drop, significant injury could occur.

- Take care when loading stock that it is clamped firmly and set up so that as many of the teeth can be in contact with the material as possible. For rectangular stock this would mean placing the long side parallel with the floor. Doing these things will protect the blade from damage and reduce the chance of the material coming loose during a cut.

- After making a cut, the material will have a sharp burr and may be hot to the touch. Let the part cool and remove the burr with a file or a deburring tool.

- Before making a large cut, ask the shop supervisor to wax the blade.

- If the machine is knocking, stop the machine and inform the shop supervisor. There may be a metal chip clogging the blade.

Description

A horizontal band saw is a type of band saw where the piece stays stationary and the cutting head is a band saw arranged horizontally that cuts into the part by gravity assist. Our horizontal bandsaw in the shop is the Ellis Model 1600. It can be used to rough cut metal or plastic (NO WOOD) stock to length. It has a cutting capacity of 10" Round and 10" by 8" rectangle at 90 degrees or 6-7/8" round and 8" by 6" rectangle when rotated to 45 degrees.

Documentation

Terminology

- Kerf - The slit made by cutting with a saw. This is important to keep in mind when positioning the cut or the final cut may end up shorter than desired.

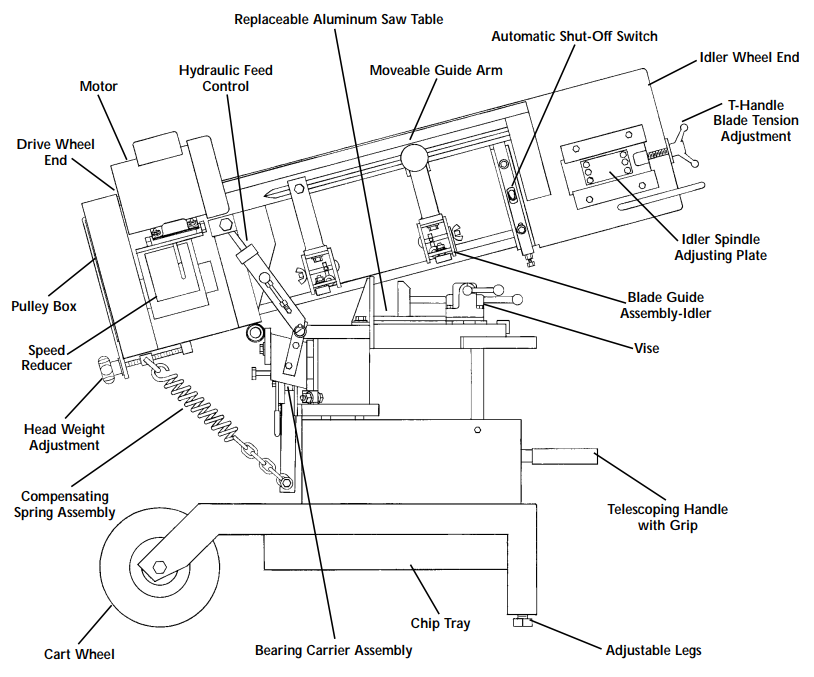

- Horizontal Bandsaw Components:

User Manual

Horizontal Bandsaw User Manual

Training

Operation

The first thing you will want to do is mark your stock where it should be cut. Once that is done place the material on the saw table and lower the blade to just above the material so you can accurately line the saw blade up with the mark on the material. If you are cutting rectangular stock make sure the longer side is the one on table. This allows more of the blade teeth to engage the material and lowers the stress on the blade as a result. To lower the blade, hold the handle on the idler wheel end of the saw with one hand and then open the hydraulic feed control by twisting the knob counterclockwise with the other hand. Lower the bade to just above the material and then close the feed control to hold the blade in place. Line up your mark with the saw blade but don't forget about the blade kerf if you are concerned about accuracy. Clamp the material in place with the vice and apply some oil to the cut area. You are now ready to cut. Press the green button to turn on the saw and then open the feed control slightly and keep one hand on the handle of the machine head to slowly lower the blade. Once the blade has a cut the depth of the teeth you can let go and gravity will feed the saw. The saw will automatically turn off when the cut is complete, but if you need to stop the saw during the cut press the red emergency stop button. Reset the space when you are done. All shavings should be cleaned up and disposed of properly. Put any extra stock back in its respective spot. When finished, make sure the blade arm is laying completely down so that the auto shutoff switch is engaged and no one can fit anything under the blade without raising the arm.

Demonstration

Cut a 1.375” long piece of 1” aluminum round stock for the lathe demonstration part.

General Procedure

This video contains specific information for using the Horizontal Bandsaw in the Maker Hub as well as a basic overview of what will be expected in your live demonstration.

Reset the Space

Here is how you can reset the space for the Horizontal Bandsaw. Always leave the space better than you found it!!!

- Turn off the machine.

- Vacuum and clean the horizontal bandsaw.

- Put any unused materials back on the storage shelf and put small pieces in the scrap box.

- Lower the blade and tighten the knob so that the blade stays in place.

Certification

Complete the Machine Shop - Horizontal Bandsaw Module at the link below to gain access to the Horizontal Bandsaw. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email makerhub@georgefox.edu if you have any questions.

Troubleshooting

- Not cutting smoothly - Slow the drop rate. If this issue persists ask the shop supervisor to wax the blade and remove any metal chips clogging the teeth.

Maintenance

General maintenance

The most important maintenance procedure for the Horizontal Bandsaw is to keep it clean by vacuuming up any metal chips created by a cut. Also, the Bandsaw should be waxed every couple of cuts or if the Bandsaw is not cutting smoothly. If the Bandsaw continues to kick, you may unplug the machine and use pliers to remove metal chunks stuck to the blade

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Clean up Metal Chips | After each use | Student |

| Wax the Blade | As needed | Shop Supervisor |