Difference between revisions of "Sheet Metal Shear"

| Line 52: | Line 52: | ||

====Operation==== | ====Operation==== | ||

| − | The sheet metal shear is human powered. | + | The sheet metal shear is human powered. You will be pressing down on the foot pedal to move the blade that shears the material. The upper rail has two handles for clamping down your work prior to shearing.The shear is rated for 16 gauge mild steel but it would be very difficult to cut a full width of material with this machine. It is recommended that you stick to thinner and smaller pieces of material when using the machine. This machine is not designed to cut round stock and it will ruin the blade. Keep body parts away from the blade at all times. Don't stick anything you wouldn't want cut off under the blade. This machine is not designed to cut round stock and it will ruin the blade. |

====Demonstration==== | ====Demonstration==== | ||

Revision as of 17:06, 16 July 2020

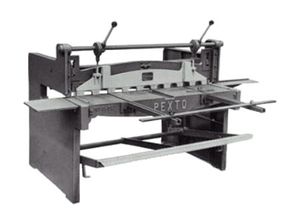

Make: Peck, Stow & Wilcox Co.

Model: G-52

Ace: Needed (Makerhub@georgefox.edu).

Location: Machine Shop

Description

The shear is used for making straight cuts in sheet metal as well as other materials. The shearing blade is powered by applying force to the foot bar located in front of the machine. To prevent damage to yourself and or the machine make sure you obey the following rules:

- Maximum aluminum material thickness you can cut with this machine is .07" x full width.

- Maximum mild steel thickness you can cut with this machine is .06" x 12" wide

- Maximum stainless steel thickness you can cut with this machine is .04" x 12" (ask before cutting stainless steel)

- NEVER attempt to cut round stock or wire on the shear.

- Plastics can be cut up to 1/8" thick x the blade width.

- Ask Justin or Nick G. prior to cutting any other materials.

- Always use the cam lock bar to hold material prior to cutting.

Here is an example of this piece of equipment being used.

Documentation

Terminology

- Foot Pedal: The bar located across the front of the machine used to activate the blade.

- Hold Down: A cam operated bar in front of the blade used to keep the material from moving during a cut.

- Hold Down Handles: The handles used to actuate hold down clamp.

Manual Media:NO.G52.pdf

Training

Operation

The sheet metal shear is human powered. You will be pressing down on the foot pedal to move the blade that shears the material. The upper rail has two handles for clamping down your work prior to shearing.The shear is rated for 16 gauge mild steel but it would be very difficult to cut a full width of material with this machine. It is recommended that you stick to thinner and smaller pieces of material when using the machine. This machine is not designed to cut round stock and it will ruin the blade. Keep body parts away from the blade at all times. Don't stick anything you wouldn't want cut off under the blade. This machine is not designed to cut round stock and it will ruin the blade.

Demonstration

For the demonstration you will need to show understanding of the machine use and setup. You will need to select an appropriate piece of material for the demonstration and make a safe cut. By placing a mark on the material you can demonstrate your ability to align the blade with the cut line.

General Procedure

Insert text

Safety

- Fingers must be kept away from the blade at all times. Never place your hand or fingers near the blade.

- Sheet metal can be razor sharp. Always be aware of sharp edges and corners. It is recommended to use gloves when handling sheet metal.

Certification

Troubleshooting

Maintenance

General maintenance

The machine should be oiled periodically by the tech.

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |