Difference between revisions of "Hand Router"

| Line 36: | Line 36: | ||

== Training == | == Training == | ||

| − | Click on [https://www.youtube.com/watch?v=8Vl8Jbw3cSk this] link for an introductory video on using the router. The enthusiastic video's most important parts happen in the first 8 minutes. Note that we do not have a router table, but one can easily be made. If the proper direction of cut is confusing, [https://www.youtube.com/watch?v=5Qqimqo-ohU this] video explains it thoroughly, albeit in a very lengthy fashion. Our router accepts both 1/2" and 1/4" | + | Click on [https://www.youtube.com/watch?v=8Vl8Jbw3cSk this] link for an introductory video on using the router. The enthusiastic video's most important parts happen in the first 8 minutes. Note that we do not have a router table, but one can easily be made. If the proper direction of cut is confusing, [https://www.youtube.com/watch?v=5Qqimqo-ohU this] video explains it thoroughly, albeit in a very lengthy fashion. Our router accepts both 1/2" and 1/4" bit shanks, just swap out collets to change bit shank size. |

Revision as of 16:22, 12 April 2019

The hand router is the most dangerous tool in the wood shop, but it can also be one of the most versatile tools. Used in conjunction with the proper jigs and templates, the router can accomplish a wide variety of tasks with relative ease. Holes and channels of varying depths and nearly limitless shapes can be cut. The router can also use special bits to cut bevels and chamfers along the edges of a workpiece.

The current Ace of the Hand Router is Needed (Makerhub@georgefox.edu).

Documentation

File:HandRouterManual890 series.pdf

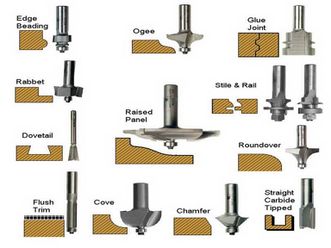

Bit Types

Each bit is made for a different job. The wood shop has a wide assortment, although less common types may be unavailable. It should be noted that different bit sizes and profiles will operate better at different speeds. The amount of material the is being removed in each pass as well as the hardness of the wood should determine the speed the router is ran at. With reference to straight bits, if the bit is less than 1" in diameter, many recommend speeds near 24,000 rpm. For bits 1" - 2.5", 16,000 to 18,000 rpm, 2.5" to 3", 12,000 to 14,000 rpm, and for bits of more than 3", a common recommendation is 10,000 to 12,000 rpm.

Occasionally routing can leave burn marks on the workpiece. This usually means that the bit in the router has become dull, let a shop supervisor know if a bit seems dull. Sometimes the burning is due to build up of resin and other gunk (a technical term) on the back of the blade insulating the bit and allowing for heat to build up, make sure to keep bits clean. A final possible cause of burning wood while routing is taking passes that are too slow or setting the router bit speed too high.

Training

Click on this link for an introductory video on using the router. The enthusiastic video's most important parts happen in the first 8 minutes. Note that we do not have a router table, but one can easily be made. If the proper direction of cut is confusing, this video explains it thoroughly, albeit in a very lengthy fashion. Our router accepts both 1/2" and 1/4" bit shanks, just swap out collets to change bit shank size.