Difference between revisions of "Through Hole Press"

| Line 35: | Line 35: | ||

====General Procedure==== | ====General Procedure==== | ||

| − | + | # Hole Sizing | |

| − | + | ## Before pressing a rivet, you need to make sure you design the holes so that they fit well. For a rivet to fit nicely in a hole, the hole diameter need to be 0.1 mm (3.9 mils) larger than the outer rivet diameter. Use the table below to see what types of rivets Voltera offers.[[File:...rivetTable.png|none|thumb]] | |

| + | ## Additionally, these rivets are hollow, so these can also be used to secure headers on your PCB. When placing vias in your design program, ensure the right drill size is used so the V-One leaves enough space when printing the ink. | ||

| + | # Using Through Hole Press | ||

| + | ## You will need to play all the rivets into the board. Some like to use their fingers, some like to use tweezers, it is up to you. Pinching the rivets on the side is the easiest way to go, as shown in the picture below. | ||

==Safety== | ==Safety== | ||

| Line 98: | Line 101: | ||

<br /><br /> | <br /><br /> | ||

| − | <figure-inline><figure-inline><figure-inline><figure-inline><figure-inline>[[File:through hole press chart snippet.PNG|750x750px]]</figure-inline></figure-inline></figure-inline></figure-inline></figure-inline> | + | <figure-inline><figure-inline><figure-inline><figure-inline><figure-inline><figure-inline>[[File:through hole press chart snippet.PNG|750x750px]]</figure-inline></figure-inline></figure-inline></figure-inline></figure-inline></figure-inline> |

<br /><br /> | <br /><br /> | ||

Revision as of 14:10, 19 June 2019

Make: Bungard

Model: PL-FAVORIT

Ace: Needed (Makerhub@georgefox.edu).

Location: PCB Lab

Description

The Through Hole Press is a hand-operated through hole plating machine using rivets. A rivet is a component used to easily connect traces that are transitioning between the top and bottom layers of a PCB. Specifically, it is a small hollow copper tube that can be inserted on one side of the board, then - using a specialized rivet tool like the Through Hole press - the rivets are pressed and deformed to connect both sides. There are other methods that carry out the same function, but using rivets is the fastest and most consistent method.

Documentation

Terminology

Favorit Through Hole Press User Manual

Training

Overview

Rivets are used to connect traces on the top and bottom layers of a PCB. Rivets can be pressed using either the Through Hole Press or a rubber mallet. Each method has its perks, so students will learn both methods.

Demonstration

To show a complete knowledge of the press, the student will press 2 rivets by using a rubber mallet and 2 rivets using the press. A test PCB with many holes of different sizes will be provided and reused among students.

General Procedure

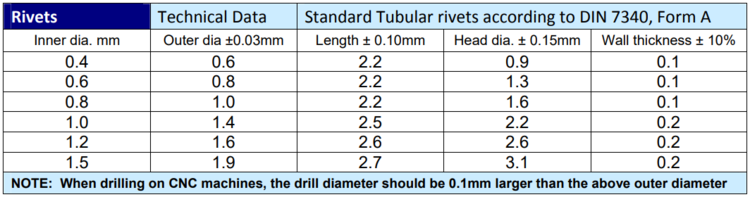

- Hole Sizing

- Before pressing a rivet, you need to make sure you design the holes so that they fit well. For a rivet to fit nicely in a hole, the hole diameter need to be 0.1 mm (3.9 mils) larger than the outer rivet diameter. Use the table below to see what types of rivets Voltera offers.

- Additionally, these rivets are hollow, so these can also be used to secure headers on your PCB. When placing vias in your design program, ensure the right drill size is used so the V-One leaves enough space when printing the ink.

- Using Through Hole Press

- You will need to play all the rivets into the board. Some like to use their fingers, some like to use tweezers, it is up to you. Pinching the rivets on the side is the easiest way to go, as shown in the picture below.

Safety

Insert text

Certification

Foxtale Quiz

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |

Here would be info about this equipment.

The current Ace of the Through Hole Press is Needed (Makerhub@georgefox.edu).

Documentation

Training

Rivet and Drill Sizes

Use this information to determine the size hole to drill for the desired rivet.

<figure-inline><figure-inline><figure-inline><figure-inline><figure-inline><figure-inline>

Adjusting the Tool Set

Riveting Process