Difference between revisions of "Soldering Irons"

| Line 19: | Line 19: | ||

==Processes== | ==Processes== | ||

| − | [[File:Brazing and soldering processes - AWS A3.0 2001.svg|thumb|right|300px|Brazing and soldering processes | + | [[File:Brazing and soldering processes - AWS A3.0 2001.svg|thumb|right|300px|Brazing and soldering processes]] |

There are three forms of soldering, each requiring progressively higher temperatures and producing an increasingly stronger joint strength: | There are three forms of soldering, each requiring progressively higher temperatures and producing an increasingly stronger joint strength: | ||

# soft soldering, which originally used a tin-lead [[alloy]] as the filler metal | # soft soldering, which originally used a tin-lead [[alloy]] as the filler metal | ||

Revision as of 14:08, 17 February 2018

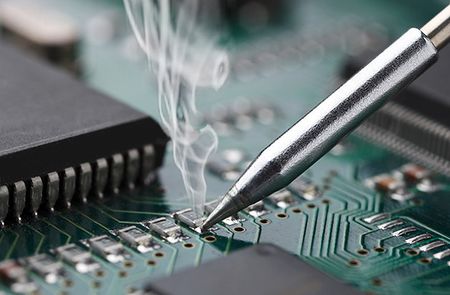

Soldering, is a process in which two or more items (usually metal) are joined together by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Soldering differs from welding in that soldering does not involve melting the work pieces. In brazing, the filler metal melts at a higher temperature, but the work piece metal does not melt. In the past, nearly all solders contained lead, but environmental and health concerns have increasingly dictated use of lead-free alloys for electronics and plumbing purposes.

Thing 1

There is evidence that soldering was employed as early as 5

Applications

Soldering is used in plumbing, electronics, and metalwork from flashing to jewelry.

Solders

Soldering filler materials are available in many different alloys for differing applications. In electronics assembly, the eutectic alloy of 63% tin and 37% lead (or 60/40, which is almost identical in melting point) has been the alloy of choice. Other alloys are used for plumbing, mechanical assembly, and other applications. Some examples of soft-solder are tin-lead for general purposes, tin-zinc for joining aluminium, lead-silver for

Flux

The purpose of flux is to facilitate the soldering process. One of the obstacles to a successful solder joint is an impurity at the site of the joint, for example, dirt, oil or oxidation. The

Flux performance must be carefully evaluated for best results; a very mild 'no-clean' flux might be perfectly acceptable for production equipment, but not give adequate performance for more variable hand-soldering operations.

Processes

There are three forms of soldering, each requiring progressively higher temperatures and producing an increasingly stronger joint strength:

- soft soldering, which originally used a tin-lead alloy as the filler metal

- silver soldering, which uses an alloy containing silver

- brazing which uses a brass alloy for the filler

Lead-free electronic soldering

More recently environmental legislation has specifically targeted the wide use of lead in the electronics industry. The RoHS directives in Europe required many new electronic circuit boards to be lead free by 1 July 2006, mostly in the consumer goods industry, but in some others as well. In Japan lead was phased out prior to legislation by manufacturers due to the additional expense in recycling products containing lead.

Electronics

Various problems may arise in the soldering process which lead to joints which are nonfunctional either immediately or after a period of use.