Difference between revisions of "Bending Brake"

Jump to navigation

Jump to search

Jwhipple15 (talk | contribs) |

|||

| Line 6: | Line 6: | ||

|Is located in facility= Machine Shop | |Is located in facility= Machine Shop | ||

|Is used in domain=Metal | |Is used in domain=Metal | ||

| + | |Has name={{PAGENAME}} | ||

|Has function=Steel Bending Brake | |Has function=Steel Bending Brake | ||

|Has url=http://www.tennsmith.com/foot-squaring-shears.html | |Has url=http://www.tennsmith.com/foot-squaring-shears.html | ||

| Line 13: | Line 14: | ||

|Has imagedesc=48 inch bending brake, 14 gauge | |Has imagedesc=48 inch bending brake, 14 gauge | ||

|Has description=48 inch bending brake, 14 gauge | |Has description=48 inch bending brake, 14 gauge | ||

| + | |Has ace=Noah Bloomquist;nbloomquist17@georgefox.edu | ||

}} | }} | ||

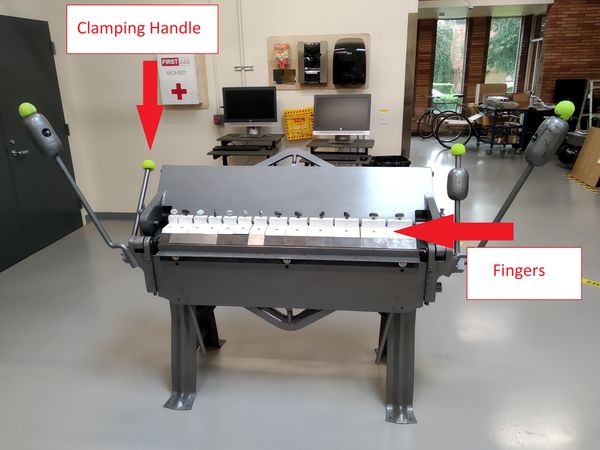

[[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|100px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]][[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]]A bending brake is a metalworking machine that allows the bending of sheet metal. The brake in the shop is a Chicago W31 steel box and pan brake. In a box-and-pan brake (also known as a finger brake), the clamping bar includes several removable blocks, which may be removed and rearranged to permit bending of restricted areas of a piece of sheet metal or of already partially formed pieces. After bending, a box or pan form is then completed by screw, solder, weld, rivet, or other metal fixing process. | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|100px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]][[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]]A bending brake is a metalworking machine that allows the bending of sheet metal. The brake in the shop is a Chicago W31 steel box and pan brake. In a box-and-pan brake (also known as a finger brake), the clamping bar includes several removable blocks, which may be removed and rearranged to permit bending of restricted areas of a piece of sheet metal or of already partially formed pieces. After bending, a box or pan form is then completed by screw, solder, weld, rivet, or other metal fixing process. | ||

<br> | <br> | ||

| + | |||

| + | The current Ace of the {{PAGENAME}} is '''{{#show: {{PAGENAME}} |?Has ace.Has name}}''' ({{#show: {{PAGENAME}} |?Has ace.Has email address}}).<br /> | ||

| + | __TOC__ | ||

== Resources == | == Resources == | ||

Revision as of 13:20, 4 March 2019

A bending brake is a metalworking machine that allows the bending of sheet metal. The brake in the shop is a Chicago W31 steel box and pan brake. In a box-and-pan brake (also known as a finger brake), the clamping bar includes several removable blocks, which may be removed and rearranged to permit bending of restricted areas of a piece of sheet metal or of already partially formed pieces. After bending, a box or pan form is then completed by screw, solder, weld, rivet, or other metal fixing process.

The current Ace of the Bending Brake is Needed (Makerhub@georgefox.edu).

Resources

Training

Bending Steps

- Ensure that your sheet metal is thinner or equivalent to 14-gauge sheet metal, and ensure that it is less than 48" in width.

- If making a bend for a box or a pan, adjust the fingers so that the equivalent width of the fingers is just shorter than your sheet metal.

- Adjust the clamping force and the clamping handle to allow room to insert your work piece.

- Insert your work piece to the line you want to bend, centered in the brake, and clamp your piece securely.

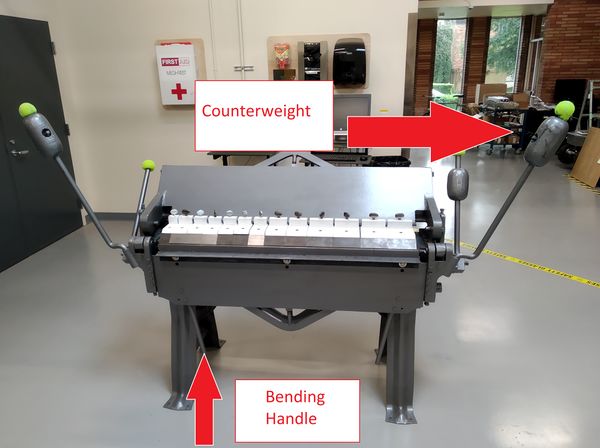

- Pull up on the bending handle slowly until your piece is bent to the desired angle, and slowly lower the leaf.

- Adjust the clamp handle, and remove your piece.

- Put back any fingers if adjusted, and deburr if any rough edges are left.

Safety

- Always make sure your hands are out of the way of the fingers and all moving parts.

- Be aware of your surroundings to ensure that you do not bump others with the counterweight.

- If bending a small piece of metal, place it in the center of the brake. (If you don't it can damage the machine)

- You may not use the sheet metal machines without safety glasses!! (Should be obvious if you are following the rules of the shop)