Difference between revisions of "Prusa 3D Printer"

Jwhipple15 (talk | contribs) |

Dklinkner18 (talk | contribs) (Added more terminology to the list) |

||

| Line 37: | Line 37: | ||

=== Feeder === | === Feeder === | ||

| − | ... | + | The feeder is the part of the 3D printer that "feeds" the filament to the nozzle. Sometimes "feeder" and "extruder" are used synonomously, so it's important when you're teaching someone to differentiate whether or not you're talking about the ''nozzle'' extruder or the ''feeder'' extruder. |

| + | |||

| + | Feeders are typically composed of stepper motors, gears, and sometimes bolts and pulleys to guide the filament to the hotend. | ||

=== Fan === | === Fan === | ||

| − | ... | + | There are usually two fans on the nozzle of a 3D printer, and they serve the purpose of cooling the plastic as soon as it comes out of the nozzle. If the plastic is super hot, we don't want it to move as soon as it is in place on the part we're making, otherwise our part will turn out warped or failed. The fans are put in place to strategically cool the plastic as soon as it comes out of the nozzle. |

| + | |||

| + | You are able to turn the fan speeds up and down in the slicer software (if that is a provided feature), but you can manually configure it on the printer as well. | ||

=== Stepper Motor === | === Stepper Motor === | ||

| − | ... | + | There are two main places where you'll find stepper motors on a 3D printer. There's a motor for each axes, one for the x, y, and z. These motors receive instructions from the gcode to move the certain axes at certain points to create your print. |

| + | |||

| + | There is also a stepper motor in the extruder setup, pushing and pulling the filament whenever more or less is needed for the current print. | ||

=== Filament === | === Filament === | ||

There are many different kinds of filament you can use on the 3D printer, ranging from PLA, ABS, TPU, and Nylon. The most common of these are PLA and ABS. | There are many different kinds of filament you can use on the 3D printer, ranging from PLA, ABS, TPU, and Nylon. The most common of these are PLA and ABS. | ||

| − | PLA stands for Polylactic Acid, it is the most common desktop 3D printing filament because it is odorless and very hard to warp on its own, therefore | + | PLA stands for Polylactic Acid, it is the most common desktop 3D printing filament because it is odorless and very hard to warp on its own, therefore not always a need for a heated bed. |

| + | |||

| + | ABS stands for Acrylonitrile Butadiene Styrene. It's one of the most commercial versions of plastic available (found in legos, packaging, and more)--it's durable, scratch resistant, and tough. Heated beds are a must with ABS filament because it is so temperature sensitive, so it warps very easily. | ||

==== Sizing of Filament ==== | ==== Sizing of Filament ==== | ||

| − | ... | + | There are two mainstream sizes of filament, 3.00mm and 1.75mm. The 3.00mm filament is typically used on higher end machines--printing stronger and more detailed models. Hobbyist printers lean more towards the 1.75mm filament, for marketing purposes as well as hardware purposes. The Prusa i3's use 1.75mm filament. |

=== CAD Modeling and Thingiverse === | === CAD Modeling and Thingiverse === | ||

| Line 66: | Line 74: | ||

* things that can go wrong | * things that can go wrong | ||

* how to finish a print | * how to finish a print | ||

| + | |||

| + | == Troubleshooting == | ||

| + | * failed calibration | ||

| + | * crash detected | ||

| + | * debris on nozzle | ||

Revision as of 16:49, 10 October 2018

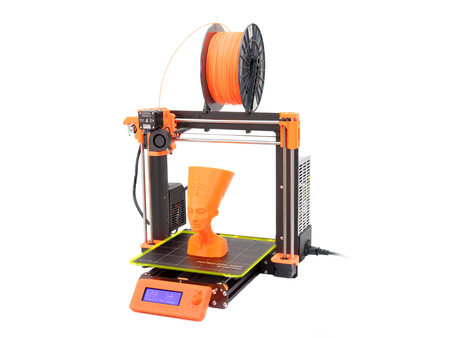

The Prusa i3 MK3 is a 3D printer that includes a removable heatbed, filament sensor, and other unique features in order to rapidly prototype projects.

Documentation

Training

Terminology

Nozzle/Extruder

The nozzle (or extruder) is the part of a 3D printer which deposits the molten plastic filament onto the 3D printer bed. The extruder can reach 200°-300°C, depending on the filament used, but typically stays around 215°C for regular prints.

Heatbed

The heatbed is a 9.83" x 8.3" x 8.3" plate where the filament will be "printed" on. The bed heats up to around 60°C. Heated beds typically prevent the plastic from warping by keeping it warm. Warping is a common issue that happens on 3D printers, where the plastic of the print cools at an uneven rate, leaving the print wavy and not the way you intentioned.

Feeder

The feeder is the part of the 3D printer that "feeds" the filament to the nozzle. Sometimes "feeder" and "extruder" are used synonomously, so it's important when you're teaching someone to differentiate whether or not you're talking about the nozzle extruder or the feeder extruder.

Feeders are typically composed of stepper motors, gears, and sometimes bolts and pulleys to guide the filament to the hotend.

Fan

There are usually two fans on the nozzle of a 3D printer, and they serve the purpose of cooling the plastic as soon as it comes out of the nozzle. If the plastic is super hot, we don't want it to move as soon as it is in place on the part we're making, otherwise our part will turn out warped or failed. The fans are put in place to strategically cool the plastic as soon as it comes out of the nozzle.

You are able to turn the fan speeds up and down in the slicer software (if that is a provided feature), but you can manually configure it on the printer as well.

Stepper Motor

There are two main places where you'll find stepper motors on a 3D printer. There's a motor for each axes, one for the x, y, and z. These motors receive instructions from the gcode to move the certain axes at certain points to create your print.

There is also a stepper motor in the extruder setup, pushing and pulling the filament whenever more or less is needed for the current print.

Filament

There are many different kinds of filament you can use on the 3D printer, ranging from PLA, ABS, TPU, and Nylon. The most common of these are PLA and ABS.

PLA stands for Polylactic Acid, it is the most common desktop 3D printing filament because it is odorless and very hard to warp on its own, therefore not always a need for a heated bed.

ABS stands for Acrylonitrile Butadiene Styrene. It's one of the most commercial versions of plastic available (found in legos, packaging, and more)--it's durable, scratch resistant, and tough. Heated beds are a must with ABS filament because it is so temperature sensitive, so it warps very easily.

Sizing of Filament

There are two mainstream sizes of filament, 3.00mm and 1.75mm. The 3.00mm filament is typically used on higher end machines--printing stronger and more detailed models. Hobbyist printers lean more towards the 1.75mm filament, for marketing purposes as well as hardware purposes. The Prusa i3's use 1.75mm filament.

CAD Modeling and Thingiverse

...

Slicing

Gcode

...

Usage

- starting a print

- loading filament

- things that can go wrong

- how to finish a print

Troubleshooting

- failed calibration

- crash detected

- debris on nozzle