Difference between revisions of "Blast Cabinet"

| Line 44: | Line 44: | ||

==Training== | ==Training== | ||

====Operation==== | ====Operation==== | ||

| − | The blast cabinet contains tiny glass beads in the bottom. There is a large wire mesh that divides the upper and lower sections of the cabinet. The foot pedal is connected to compressed air and controls the volume of air going to the nozzle. The air passing through the nozzle creates a vacuum and draws the glass beads in the bottom of the machine up into the air stream in the nozzle. The glass beads are rapidly accelerated into the part you are bead blasting. The beads fall back into the bottom of the cabinet and are recycled through the system. | + | The blast cabinet contains tiny glass beads in the bottom. There is a large wire mesh that divides the upper and lower sections of the cabinet. The foot pedal is connected to compressed air and controls the volume of air going to the nozzle. The air passing through the nozzle creates a vacuum and draws the glass beads in the bottom of the machine up into the air stream in the nozzle. The glass beads are rapidly accelerated into the part you are bead blasting. The beads fall back into the bottom of the cabinet and are recycled through the system. |

| − | |||

====Demonstration==== | ====Demonstration==== | ||

Revision as of 16:56, 27 May 2020

Make: Skat Blast

Model: SC-40

Ace: Needed (Makerhub@georgefox.edu).

Location: Welding Shop

Description

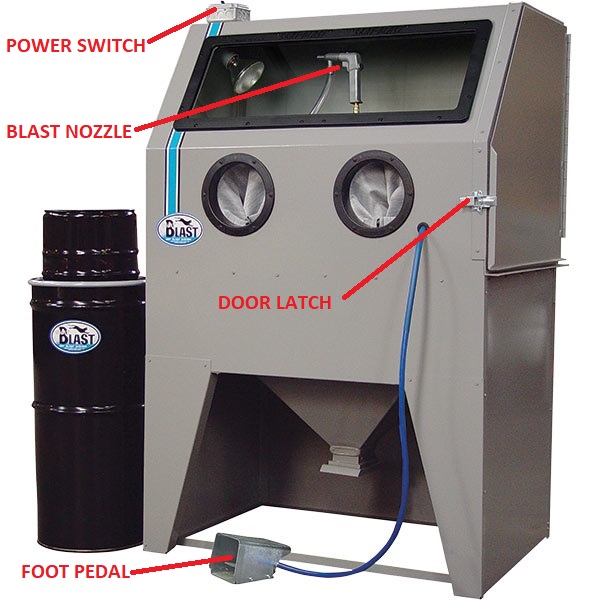

The 960-DLX DELUXE Skat Blast Cabinet has become one of "America's Favorites". TWO 90 watt floodlights and big 12" x 33" window for improved, brighter visibility when blasting. Plus, Skat Blast's C-35-M Foot-Pedal-Operated Power Gun and pickup tube system for a more powerful, even blast. Quiet Vac-50 HEPA Vacuum with HEPA Filtration collects 99.97% dust particles down to 0.3 microns.

Here is an example of this piece of equipment being used.

Documentation

Terminology

Insert terminology here

Training

Operation

The blast cabinet contains tiny glass beads in the bottom. There is a large wire mesh that divides the upper and lower sections of the cabinet. The foot pedal is connected to compressed air and controls the volume of air going to the nozzle. The air passing through the nozzle creates a vacuum and draws the glass beads in the bottom of the machine up into the air stream in the nozzle. The glass beads are rapidly accelerated into the part you are bead blasting. The beads fall back into the bottom of the cabinet and are recycled through the system.

Demonstration

Demonstrate you can safely setup the blast cabinet and use a stencil to produce a design on acrylic. The stencil will protect certain areas of acrylic from the glass beads. The beads causes the acrylic to have a frosted look.

General Procedure

- Tape existing stencil to a piece of acrylic scrap. The stencil will only allow abrasion in the areas desired.

- Open the cabinet door using the door latch.

- Place the stencil/acrylic into sandblast cabinet

- Make sure to secure the door using the latch. If the door is left open it will create a cloud of dust that should not be inhaled.

- Turn on the cabinet light and fan with the power switch located on the top left of the machine.

- Insert your arms into the gloves and position yourself for a clear view into the cabinet.

- You may need to hold the corner of the part down while blasting, manually aim where the stencil doesn't cover the acrylic. Do not point the gun at your gloves or the window.

- Position your foot in the foot pedal mechanism. Once the pedal is depressed sand will blast out of the nozzle.

- Keep the nozzle 3 to 4" away from the acrylic and keep the nozzle moving so it keeps a consistent frost pattern.

- Before removing parts, wait 5-10 mins after turning off the power switch. This allows time for the dust in the cabinet to settle.

- Once you remove parts make sure to close the cabinet door and turn the power switch to the off position.

Safety

- Make sure the cabinet door is closed before stepping on the air activation pedal.

- Keep the activation pedal clear when loading the cabinet.

- After you are done using the blaster let the dust in the cabinet settle prior to opening the door.

- Inhaling the dust produced by the cabinet is bad for your lungs.

- Never point the nozzle towards your hand or the window in the cabinet.

Certification

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Nozzle Change | As Needed | Ace/Tech |