Difference between revisions of "Horizontal Bandsaw"

| Line 68: | Line 68: | ||

====General maintenance==== | ====General maintenance==== | ||

| − | The Bandsaw should be waxed every couple of cuts or if the Bandsaw is not cutting smoothly. If the Bandsaw continues to kick, you may unplug the machine and use pliers to remove metal chunks stuck to the blade | + | The most important maintenance procedure for the Horizontal Bandsaw is to keep it clean by vacuuming up any metal chips created by a cut. Also, the Bandsaw should be waxed every couple of cuts or if the Bandsaw is not cutting smoothly. If the Bandsaw continues to kick, you may unplug the machine and use pliers to remove metal chunks stuck to the blade |

====Specific Maintenance Tasks==== | ====Specific Maintenance Tasks==== | ||

Revision as of 08:12, 23 July 2019

Make: Ellis Mfg. Company Inc.

Model: 1600

Ace: Needed (Makerhub@georgefox.edu).

Location: Machine Shop

Description

A horizontal band saw is a type of band saw where the piece stays stationary and the cutting head is a band saw arranged horizontally that cuts into the part by gravity assist. Our horizontal bandsaw in the shop is the Ellis Model 1600. It can be used to rough cut metal or plastic (NO WOOD) stock to length. It has a cutting capacity of 10" Round and 10" by 8" rectangle at 90 degrees or 6-7/8" round and 8" by 6" rectangle when rotated to 45 degrees.

Documentation

Terminology

- Kerf - The slit made by cutting with a saw. This is important to keep in mind when positioning the cut or the final cut may end up shorter than desired.

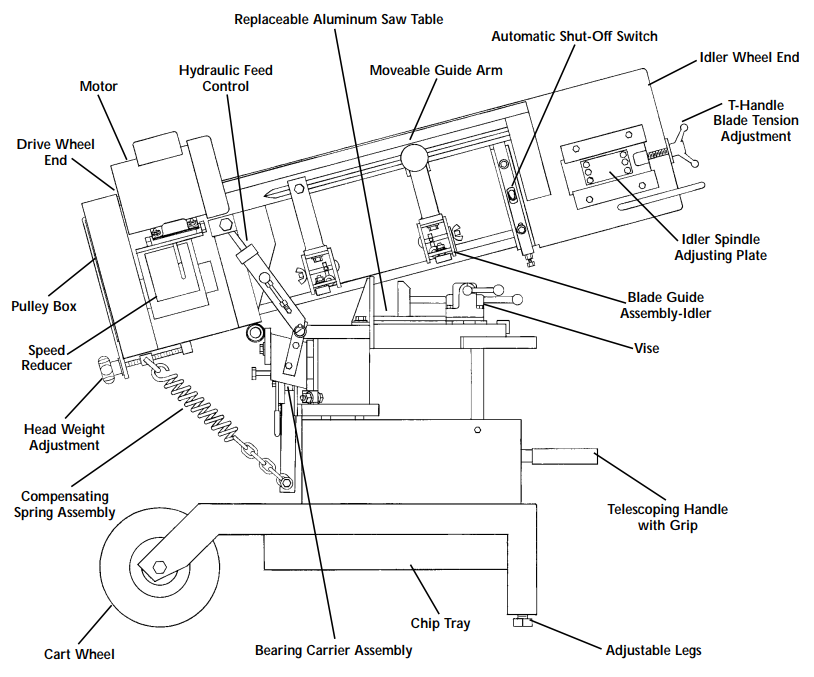

- Horizontal Bandsaw Components:

User Manual

Training

Overview

All shavings should be cleaned up and disposed of properly. Put any extra stock back in its respective spot. When finished, make sure the blade arm is laying completely down so that the auto shutoff switch is engaged and no one can fit anything under the blade without raising the arm.

Demonstration

Cut a 1” long piece of ½” round stock.

General Procedure

This video contains specific information for using the Horizontal Bandsaw in the Maker Hub as well as a basic overview of what will be expected in your live demonstration.

Safety

- Never place your hand below the blade. If, for some reason, the blade were to drop, significant injury could occur.

- Take care when loading stock that it is clamped firmly and set up so that as many of the teeth can be in contact with the material as possible. For rectangular stock this would mean placing the long side parallel with the floor. Doing these things will protect the blade from damage and reduce the chance of the material coming loose during a cut.

Certification

Troubleshooting

- Not cutting smoothly - Slow the drop rate. If this issue persists ask the shop supervisor to wax the blade and remove any metal chips clogging the teeth.

Maintenance

General maintenance

The most important maintenance procedure for the Horizontal Bandsaw is to keep it clean by vacuuming up any metal chips created by a cut. Also, the Bandsaw should be waxed every couple of cuts or if the Bandsaw is not cutting smoothly. If the Bandsaw continues to kick, you may unplug the machine and use pliers to remove metal chunks stuck to the blade

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Clean up Metal Chips | After each use | Student |

| Wax the Blade | As needed | Shop Supervisor |