Difference between revisions of "Reflow Oven"

| (One intermediate revision by one other user not shown) | |||

| Line 17: | Line 17: | ||

|Has certification=https://georgefox.instructure.com/courses/1297 | |Has certification=https://georgefox.instructure.com/courses/1297 | ||

|Has group=Circuit Board Design | |Has group=Circuit Board Design | ||

| − | |Has ace= | + | |Has ace=Isaac Beals;ibeals16@georgefox.edu |

}} | }} | ||

[[File:Reflow oven icon.png|left|140x140px|frameless]] | [[File:Reflow oven icon.png|left|140x140px|frameless]] | ||

| Line 84: | Line 84: | ||

Complete the <strong>PCB Lab - {{PAGENAME}} Module</strong> at the link below to gain access to the {{PAGENAME}}. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email <span style="color:blue">makerhub@georgefox.edu</span> if you have any questions. | Complete the <strong>PCB Lab - {{PAGENAME}} Module</strong> at the link below to gain access to the {{PAGENAME}}. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email <span style="color:blue">makerhub@georgefox.edu</span> if you have any questions. | ||

| − | [https://georgefox.instructure.com/enroll/ | + | [https://georgefox.instructure.com/enroll/GH36RT Maker Hub Canvas Course] |

==Troubleshooting== | ==Troubleshooting== | ||

Latest revision as of 10:14, 12 November 2024

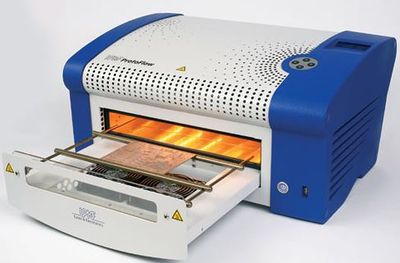

Make: LPKF

Model: ProtoFlow S N2

Serial Number: 0Z2701N343

Ace: Isaac Beals (ibeals16@georgefox.edu).

Location: PCB Lab

Description

The Reflow Oven (ProtoFlow S N2) is LPKF's premiere convection oven, ideal for lead-free reflow soldering, meeting the stringent demands of rapid PCB soldering applications. The Reflow Oven features even heat distribution, easy programming, and many pre-defined temperature profiles. The compact design and efficient power consumption make it one of the most useful components in any rapid PCB prototyping environment.

Documentation

Terminology

Training

Operation

The Reflow Oven bakes PCBs to harden the traces and pads where components are laid. It's just like your oven at home with a few extra accessories, like preset profiles that adjust the temperature and time based on the ink/paste you put on your board.

Demonstration

To show a complete knowledge of the oven, the student will have a PCB prepared by the PCB Printer and follow the instructions in the General Procedure.

General Procedure

- Power the Reflow Oven on by pressing the power button on the front.

- Select the respective ink/paste on the LCD Display. Different inks and pastes have different heat cycles, so it is important that you choose the right one. You can scroll through the options using the Up and Down keys. The Left key goes back, and the Right key selects. In this specific instance, V1 Ink is selected. Recall that each dispenser is assigned to a color. Green is V1 Ink, Orange is V1 Paste, and Blue is Sn63Pb37.

- The oven will warm up. When its ready, select "Enter" to open the tray.

- DANGER: The rails could be HOT! Take caution. Place the board securely on the rails.

- Select "Enter" to close the tray.

- The preheat will take 2 minutes. The baking process takes about 30 minutes for traces and 3 minutes for the paste.

- The tray will automatically open to initiate the cool down phase. At the end of this process, the traces and pads will harden. DO NOT remove the board until the oven says all the stages are complete. DANGER: The rails are HOT!

- When cool down is complete, remove the board from the oven, and turn off the oven.

Safety

- Never place anything in front of the oven door inside of the yellow striped area. This could result in severe damage to the oven.

- Under no circumstances may the lab be left unattended for more than a brief minute while the oven is running.

- Always follow the instructions on the LCD Display. It is your guide that keeps you safe.

- When the tray opens up after baking a board, be patient and let the board cool down. If you handle it while it is too hot, it can burn you and shift your components (not good).

- Once you are finished using the Reflow Oven, clean the inside and turn it off. RESET THE SPACE.

- If you do not want to risk being burnt by the rails when you place your board in the oven, open the tray and place your board BEFORE beginning the baking process.

- If you do get burnt, immediately place the burn under cold running cold water for a while. There is a sink to the right of the oven to help you out. This keeps it from blistering.

Certification

Complete the PCB Lab - Reflow Oven Module at the link below to gain access to the Reflow Oven. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email makerhub@georgefox.edu if you have any questions.

Troubleshooting

There are little to no issues to run into while using the oven. The most common issue is failure to select the correct profile, which results in non-hardened traces and pads. Remember, Green is V1 Ink, Orange is V1 Paste, and blue is SN63Pb37. If this happens, simply bake the board again using the correct profile. In the event that something happens out of the ordinary, follow the table below.

Maintenance

General maintenance

The oven should always be clean. Make sure it is clean before and after use. If something is not working and needs to be fixed, refer to the table above in the Troubleshooting section.

Specific Maintenance Tasks

Refer to the table in the Troubleshooting section for advanced solutions.

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Remove Debris | Before and after each use | Student |