Difference between revisions of "Formlabs 3D Printer"

| (41 intermediate revisions by 9 users not shown) | |||

| Line 4: | Line 4: | ||

|Is used in domain=Electronics | |Is used in domain=Electronics | ||

|Has name={{PAGENAME}} | |Has name={{PAGENAME}} | ||

| + | |Has make=Formlabs | ||

| + | |Has model=Form 3 | ||

| + | |Has serial number= | ||

| + | |Has life expectancy= | ||

| + | |Has year of manufacture or purchase= | ||

| + | |Has replacement cost= | ||

|Has icon=File:formlabs_printer_icon.png | |Has icon=File:formlabs_printer_icon.png | ||

|Has icondesc=Formlabs 3D Printer Icon | |Has icondesc=Formlabs 3D Printer Icon | ||

| Line 10: | Line 16: | ||

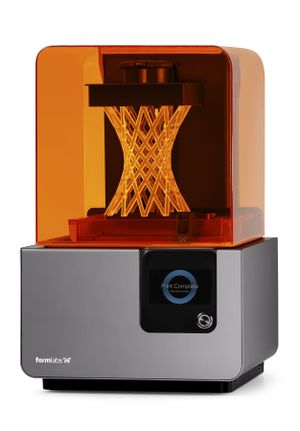

|Has imagedesc=Formlabs Form 2 3D Printer | |Has imagedesc=Formlabs Form 2 3D Printer | ||

|Has description=(???) | |Has description=(???) | ||

| − | |Has certification= | + | |Has certification=https://georgefox.instructure.com/courses/1237 |

|Has group=3D Printers | |Has group=3D Printers | ||

| − | + | |Has ace=Spencer Monkewicz;smonkewicz22@georgefox.edu | |

| − | |||

| − | |Has ace= | ||

}} | }} | ||

| − | + | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|140px|left|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]] | |

| + | [[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|thumb|300px|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]] | ||

| + | |||

Make: {{#show: {{PAGENAME}} |?Has make}} | Make: {{#show: {{PAGENAME}} |?Has make}} | ||

Model: {{#show: {{PAGENAME}} |?Has model}} | Model: {{#show: {{PAGENAME}} |?Has model}} | ||

| + | |||

| + | Serial Number: {{#show: {{PAGENAME}} |?Has serial number}} | ||

Ace: {{#show: {{PAGENAME}} |?Has ace.Has name}} ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). | Ace: {{#show: {{PAGENAME}} |?Has ace.Has name}} ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). | ||

Location: {{#show: {{PAGENAME}} |?Is located in facility}} | Location: {{#show: {{PAGENAME}} |?Is located in facility}} | ||

| + | |||

| + | |||

| + | __TOC__ | ||

==Description== | ==Description== | ||

| − | The Form | + | The Form 3 is Formlab's 3rd generation printer boasting a whole range of new features including a new peeling mechanism, heated tank, touchscreen display, wireless controls and an automated resin system. The resulting prints that come off of the Form 3 have consistently been among the highest quality objects to come off of any desktop 3D printer. This machine is best used with the [[Form Wash and Cure]] <ref name=":0">Description adapted from [https://www.3dhubs.com/3d-printers/form-2 3dhubs].</ref> |

| − | The Form | + | The Form 3 employs [[Prototype Lab#SLA Printing Anchor|SLA Printing]] (Stereolithography Apparatus). Due to friction caused by de-laminating every layer, every part should be canted in its orientation. This means the part should be angled in the PreForm software to reduce the cross sectional area needing to be shifted to de-laminate each layer. This ensures the wiper blade in the resin tank doesn't remove the print from the build plate. When reviewing the supports in PreForm, check to make sure all supports are created in areas from which they can be easily removed, or that supports created in inaccessible areas won't interfere with the print's intended function. Also check to make sure no supports are created on hard edges, as any placed supports will break up the edge, and removing them properly takes longer than necessary and can potentially damage the print. |

{{#evu:https://www.youtube.com/watch?v=8tn5zA5bNSE}} | {{#evu:https://www.youtube.com/watch?v=8tn5zA5bNSE}} | ||

| − | |||

| − | |||

==Documentation== | ==Documentation== | ||

| Line 41: | Line 50: | ||

Insert terminology here | Insert terminology here | ||

| + | <gallery> | ||

| + | File:TouchScreen.jpg|Touchscreen | ||

| + | File:...resinCartridge.jpg|Resin Cartridge | ||

| + | File:...form2BuildPlate.jpg|Build Platform | ||

| + | File:...ResinTray.png|Resin Tank | ||

| + | </gallery> | ||

| − | + | [https://support.formlabs.com/s/article/Quick-Start-Guide?language=en_US Quick Start Guide] | |

| + | |||

| + | [https://formlabs.com/3d-printers/form-2/ Product Home Page] | ||

| + | |||

| + | [https://formlabs.com/3d-printers/form-2/tech-specs/ Tech Specs] | ||

| + | |||

| + | [https://formlabs.com/3d-printers/form-2/design-specs/ Design Specs] | ||

==Training== | ==Training== | ||

| − | ==== | + | ====Operation==== |

| − | The Form | + | The Form 3 is most useful for its ability to print incredibly accurate parts, with layers as thin as .025mm thick, depending on the resin selected. Due to the size of the Form 2, it can only be used to print smaller pieces, and the extra layering for detail combined with the de-lamination process also causes the Form 3 to generally be the slowest printer in the lab. Unless an exception is made, a model with supports included should be no larger than 30mL worth of resin. If specific material properties are needed for a print, the Form 3 is a good option to look into thanks to the many differing resins available for use. |

====Demonstration==== | ====Demonstration==== | ||

| − | To show a complete understanding of the Form | + | To show a complete understanding of the Form 3, students will prepare a part, upload it to the Form 3, and print it. |

====General Procedure==== | ====General Procedure==== | ||

| − | # Setting up PreForm | + | |

| − | ## PreForm is the software we will use to import or model to the printer. | + | #Setting up PreForm |

| − | ## To begin with, make sure the print is under the | + | ##PreForm is the software we will use to import or model to the printer. When connecting to PreForm you need to make sure the wifi is enabled and connected to bruin Secure. Make sure the correct printer is selected as well. |

| − | ## If a window pops up saying the print is broken, hit the repair button then proceed as normal. | + | ##To begin with, make sure the print is under the approved cost/size cutoff ($7), or the person printing has special approval to exceed this limit. |

| − | ## Parts must be shrunk to fit within the build area, further size edits can be made in the Size tab. | + | ##If a window pops up saying the print is broken, hit the repair button then proceed as normal. |

| − | ### The goal is to reduce the horizontal area covered with each pass of the wiper. Start with auto-orienting the part using the 'Orient Selected' button in the Orientation tab, this is a good place to start and will make it easier to see if the part needs further orientation.[[File:Size set.jpg|none|thumb| Image 1-Model too big for build plate--Image 2-Model shrunk to fit build plate]] | + | ##Parts must be shrunk to fit within the build area, further size edits can be made in the Size tab. |

| − | ## Don't place supports on hard edges (right angles) or in inaccessible places. This will cause the print to be unprintable | + | ###The goal is to reduce the horizontal area covered with each pass of the wiper. Start with auto-orienting the part using the 'Orient Selected' button in the Orientation tab, this is a good place to start and will make it easier to see if the part needs further orientation.[[File:Size set.jpg|none|thumb| Image 1-Model too big for build plate--Image 2-Model shrunk to fit build plate]] |

| − | ## Every part that needs support should have support - PreForm will highlight unsupported areas in red, place supports until the red areas go away | + | ##Don't place supports on hard edges (right angles) or in inaccessible places. This will cause the print to be unprintable. |

| − | ## Supports can be added, edited, and removed in the PreForm Supports tab. | + | ##Every part that needs support should have support - PreForm will highlight unsupported areas in red, place supports until the red areas go away. '''Check the part thoroughly because PreForm will not let you print with unsupported areas.''' |

| − | ### Support density should be between .5 and .7. | + | ##Supports can be added, edited, and removed in the PreForm Supports tab. |

| − | + | ###Support density should be between .5 and .7. '''''[Note - Is this a setting or a dimension?]''''' | |

| − | ### These values can be edited if necessary to ensure printability, just use common sense when adjusting values. | + | ###Support point size should be between .6mm and .8mm. |

| − | ## The Layout tab can be used to add additional copies of a part. | + | ###These values can be edited if necessary to ensure printability, just use common sense when adjusting values. |

| − | ## Ensure the proper printer and resin type | + | ##The Layout tab can be used to add additional copies of a part. |

| − | + | ##Ensure you are connected to Bruin Secure wifi with the proper printer and resin type selected in Preform prior to printing. Additionally, make sure that the resin you want is already installed in the printers. If the resin needs to be changed to the one that you want, ask a Lab Volunteer to help you. | |

| − | + | #Choosing a Resin Type | |

| − | ## | + | ##Go through each of these resin types to evaluate which material you will make your part out of. Once you have finished, you can send the file from the computer to the Formlabs printer |

| − | ## | + | ##Black/grey standard: the Standard Resins section of [https://support.formlabs.com/s/article/Choosing-the-Right-Material?language=en_US Choosing the Right Material]. |

| − | + | ###Pros: high detail, matte surfaces, good for small, intricate features. | |

| − | + | ###Cons: not particularly strong, stretchy, or flexible. | |

| − | ### Pros: good for | + | ##Tough: [https://support.formlabs.com/s/article/Using-Tough-Resin?language=en_US Tough] |

| − | ### Cons: | + | ###Pros: good for hard edges, snap fits, and high-stresses. |

| − | ## | + | ###Cons: bad for fine details and rigid prints, will not stretch as much as Durable. |

| − | ### Pros: | + | ##Durable: [https://support.formlabs.com/s/article/Using-Durable-Resin?language=en_US Durable] |

| − | ### Cons: bad for fine | + | ###Pros: low-friction, high impact strength, good for parts that are both rigid and flexible. |

| − | + | ###Cons: bad for fine detail parts. | |

| − | ### Pros: | + | ##Flexible: [https://support.formlabs.com/s/article/Using-Flexible-Resin?language=en_US Flexible] |

| − | ### Cons: bad for fine detail | + | ###Pros: can simulate rubber when uncured, good for functional prototyping. |

| − | ## | + | ###Cons: bad for fine detail or applications when rigidity or hardness are required. |

| − | # | + | ##See the respective links for each resin for in-depth descriptions of each resin's properties and suggested applications, or look at [https://support.formlabs.com/s/article/Choosing-the-Right-Material?language=en_US Choosing the Right Material] for a shorter overview. Most resins do not handle high temperatures or constant loading well. |

| − | # | + | #Operating the Touchscreen |

| − | ## | + | ##You will be able to start your print using the touchscreen on the Form 3. If it is sleeping, just press the button and it should wake up. |

| − | + | ##When it wakes up, you will likely see this screen. It displays the most recently prepared job and gives you the option to print now by pressing the blue button on the bottom right of the screen.[[File:TouchScreen.jpg|none|thumb]] | |

| − | + | ##There are two other buttons you can press on the left screen. The USB button will take you to the settings of the printer, so you will not need to go here. The checklist button brings a list of every job that has been uploaded to the printer, so you will want to be selecting this one to find your print. When you find your print, select "print now". The printer will make sure that you perform the appropriate setup before it starts printing, such as inserting the tank in the back of the printer and assuring that the build plate is cleared of other printed parts. | |

| − | ### | + | ##The print will begin its process once you hit Print Now! A time estimate will be provided. |

| − | ## | + | #Removing Prints |

| − | + | ##Your part should now be finished! Follow these steps to clean it up. | |

| − | ## | + | ##Finished prints |

| − | + | ###Use a scraping tool to remove the print and any extra material from the build plate, taking care to not scratch the build plate. Go as carefully and as slowly as needed to prevent damaging the print. | |

| − | + | ####The build plate stand can be used for easier removal. | |

| − | + | ###Wash the print in the Form Wash. | |

| − | ### | + | ###If the print is being cured, only remove support material after it has been run through the Form Cure. |

| − | ## | + | ###Supports should be clipped off, and any leftover support material can be sanded down if desired. |

| − | ### | + | ##Failed prints |

| − | + | ###Follow the same process for finished prints for removing. | |

| − | + | ###'''When a print fails, the build plate must be cleaned and run through the Wash''' before a new print can be started, as leftover residue from the failed print can cause subsequent prints to also fail. You will also need to check the resin tank for clumps as well as double check the model orientation. Don't forget to update the job log as well. | |

| − | ### | + | #Washing and Curing Prints |

| − | # | + | ##See the [[Form Wash and Cure]] page. |

| − | ### | + | #Changing Resin |

| − | ### | + | ##If the Formlabs Printer resin tray does not contain the resin you want, allow Lab volunteers to provide the desired resin. |

| − | # | + | ##Remove, clean, and replace the build plate. |

| − | ## | + | ###Pull lever holding build plate in place up, allowing the build plate to be removed. |

| − | ## | + | ###Place the build plate on the holding rack in the Form Wash. Run the build plate through the Wash to remove resin. For the build plate, the Wash should be set to 10 minutes. |

| − | ### | + | ###Let the build plate air dry before replacing, secure by flipping lever down. |

| − | ### | + | ##Remove and replace resin tank and wiper. |

| − | ### | + | ###Firmly pull tank back towards the touch screen until it pops loose of the printer. |

| − | ## | + | ###Place the tank in the appropriately labeled tank storage container in the cabinet under the printer. |

| − | ### | + | ###Remove the desired tank from the storage container and place the container back in the cabinet. |

| − | ## | + | ###Slot the new resin tank into place in the printer by putting it in and sliding it towards the back of the machine. |

| − | # | + | ###Use a scraping tool to dredge bottom of new resin tank for any hardened resin or loose bits of material, remove any found bits. |

| − | + | ###Be sure to clean up any resin that spills during this process. | |

| − | # | + | ##Remove and replace the resin cartridge in the back of the printer. |

| − | + | ###Close the lid of the cartridge if it's open. | |

| + | ###Pull cartridge out of the printer. | ||

| + | ###Wipe dry the resin drip on the bottom of the cartridge, then store. | ||

| + | ###Insert new resin cartridge, '''of the same resin as the tank'''. | ||

| + | ###Open lid on resin cartridge before starting a print, and close after. | ||

==Safety== | ==Safety== | ||

| − | + | The most dangerous part of using the Form 3 is taking the part off of the build plate. The scraping tool could hurt your little fingers, so make sure you do not hit them. Also, the alcohol used to clean the print is not for drinking purposes. It is both against the lifestyle contract and very harmful to you if you drink it, so do not do it. | |

| + | |||

| + | ==Approved Resins== | ||

| + | * | ||

==Certification== | ==Certification== | ||

| − | + | [https://georgefox.instructure.com/enroll/GH36RT Canvas Quiz] | |

==Troubleshooting== | ==Troubleshooting== | ||

| − | If a print fails, the most likely cause is contamination of the resin. Before proceeding, see the procedure for Failed Prints. Contamination of the resin involves leftover material on the build plate, or particulates in the resin tank. Before attempting a new print, thoroughly clean the build plate, and dredge the resin tank for any loose particles. Another cause is incorrect orientation of the print. Check the print file in question, and ensure it has been canted accordingly to prevent the de-laminating process from removing the print from the build plate. | + | If a print fails, the most likely cause is contamination of the resin. Before proceeding, see the procedure for Failed Prints. Contamination of the resin involves leftover material on the build plate, or particulates in the resin tank. Before attempting a new print, thoroughly clean the build plate, and dredge the resin tank for any loose particles. Another cause is incorrect orientation of the print. Check the print file in question, and ensure it has been canted accordingly to prevent the de-laminating process from removing the print from the build plate. Make sure to also update the job log. |

| − | Old resin and resin tanks can also present issues. If a resin tanks is particularly cloudy on the bottom, the laser will be prevented from being able to penetrate the tank, and cause adhesion issues for the print. Resin can also go bad after sitting for long periods of time or being used heavily. This can be evidenced by discoloration of the resin or separation of the resin into unmixed layers. | + | Old resin and resin tanks can also present issues. '''Don't ever mix resin types.''' If a resin tanks is particularly cloudy on the bottom, the laser will be prevented from being able to penetrate the tank, and cause adhesion issues for the print. Resin can also go bad after sitting for long periods of time or being used heavily. This can be evidenced by discoloration of the resin or separation of the resin into unmixed layers. |

==Maintenance== | ==Maintenance== | ||

====General maintenance==== | ====General maintenance==== | ||

| − | # Dredging: Every few prints the resin tank should be dredged with a scraping tool to search for any hardened resin or loose bits of material, when resin tanks are switched out, and when a print fails. Remove any found bits. Dredging is done by sweeping a scraping tool back and forth across the bottom of the resin tank, essentially mixing up the resin to stir up any loose bits. Take care while dredging to not scrape the tank. See a resin's particular page on the Formlabs website for additional cleaning instruction. If the tank is not cleanable, switch out the resin tank. If the problem persists, it's possible the resin cartridge needs to be switched out as well. | + | |

| − | # Alcohol in the Form Wash must be changed once a certain threshold of washed-off resin enters the tank. See the [[Form Wash and Cure]] page for details. | + | #Dredging: Every few prints the resin tank should be checked and dredged with a scraping tool to search for any hardened resin or loose bits of material, as well as when resin tanks are switched out, and when a print fails. Remove any found bits. Dredging is done by sweeping a scraping tool back and forth across the bottom of the resin tank, essentially mixing up the resin to stir up any loose bits. Take care while dredging to not scrape the tank. See a resin's particular page on the Formlabs website for additional cleaning instruction. If the tank is not cleanable, switch out the resin tank. If the problem persists, it's possible the resin cartridge needs to be switched out as well. |

| − | # Old resin and resin tanks will occasionally need to be changed out | + | #Alcohol in the Form Wash must be changed once a certain threshold of washed-off resin enters the tank. See the [[Form Wash and Cure]] page for details. |

| − | # [https://support.formlabs.com/hc/en-us/categories/115000003904-Form-2 Form 2 Sources and Help] | + | #Old resin and resin tanks will occasionally need to be changed out |

| + | #[https://support.formlabs.com/hc/en-us/categories/115000003904-Form-2 Form 2 Sources and Help] | ||

====Specific Maintenance Tasks==== | ====Specific Maintenance Tasks==== | ||

| Line 143: | Line 172: | ||

!Done By | !Done By | ||

|- | |- | ||

| − | | | + | |Dredging |

| − | | | + | |Every few prints |

| − | | | + | |Lab Volunteer |

| + | |- | ||

| + | |Changing Alcohol | ||

| + | |Once a certain threshold of washed-off resin enters the tank. See the [[Form Wash and Cure]] page for details. | ||

| + | |Lab Volunteer | ||

| + | |- | ||

| + | |General Cleaning | ||

| + | |Before and after each use. Reset The Space! | ||

| + | |Student | ||

|} | |} | ||

| − | |||

__TOC__ | __TOC__ | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Resources== | ==Resources== | ||

Latest revision as of 14:48, 2 September 2024

Make: Formlabs

Model: Form 3

Serial Number:

Ace: Spencer Monkewicz (smonkewicz22@georgefox.edu).

Location: Prototype Lab

Description

The Form 3 is Formlab's 3rd generation printer boasting a whole range of new features including a new peeling mechanism, heated tank, touchscreen display, wireless controls and an automated resin system. The resulting prints that come off of the Form 3 have consistently been among the highest quality objects to come off of any desktop 3D printer. This machine is best used with the Form Wash and Cure [1]

The Form 3 employs SLA Printing (Stereolithography Apparatus). Due to friction caused by de-laminating every layer, every part should be canted in its orientation. This means the part should be angled in the PreForm software to reduce the cross sectional area needing to be shifted to de-laminate each layer. This ensures the wiper blade in the resin tank doesn't remove the print from the build plate. When reviewing the supports in PreForm, check to make sure all supports are created in areas from which they can be easily removed, or that supports created in inaccessible areas won't interfere with the print's intended function. Also check to make sure no supports are created on hard edges, as any placed supports will break up the edge, and removing them properly takes longer than necessary and can potentially damage the print.

Documentation

Terminology

Insert terminology here

Training

Operation

The Form 3 is most useful for its ability to print incredibly accurate parts, with layers as thin as .025mm thick, depending on the resin selected. Due to the size of the Form 2, it can only be used to print smaller pieces, and the extra layering for detail combined with the de-lamination process also causes the Form 3 to generally be the slowest printer in the lab. Unless an exception is made, a model with supports included should be no larger than 30mL worth of resin. If specific material properties are needed for a print, the Form 3 is a good option to look into thanks to the many differing resins available for use.

Demonstration

To show a complete understanding of the Form 3, students will prepare a part, upload it to the Form 3, and print it.

General Procedure

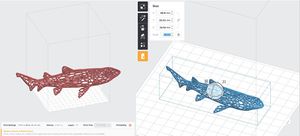

- Setting up PreForm

- PreForm is the software we will use to import or model to the printer. When connecting to PreForm you need to make sure the wifi is enabled and connected to bruin Secure. Make sure the correct printer is selected as well.

- To begin with, make sure the print is under the approved cost/size cutoff ($7), or the person printing has special approval to exceed this limit.

- If a window pops up saying the print is broken, hit the repair button then proceed as normal.

- Parts must be shrunk to fit within the build area, further size edits can be made in the Size tab.

- The goal is to reduce the horizontal area covered with each pass of the wiper. Start with auto-orienting the part using the 'Orient Selected' button in the Orientation tab, this is a good place to start and will make it easier to see if the part needs further orientation.

- Don't place supports on hard edges (right angles) or in inaccessible places. This will cause the print to be unprintable.

- Every part that needs support should have support - PreForm will highlight unsupported areas in red, place supports until the red areas go away. Check the part thoroughly because PreForm will not let you print with unsupported areas.

- Supports can be added, edited, and removed in the PreForm Supports tab.

- Support density should be between .5 and .7. [Note - Is this a setting or a dimension?]

- Support point size should be between .6mm and .8mm.

- These values can be edited if necessary to ensure printability, just use common sense when adjusting values.

- The Layout tab can be used to add additional copies of a part.

- Ensure you are connected to Bruin Secure wifi with the proper printer and resin type selected in Preform prior to printing. Additionally, make sure that the resin you want is already installed in the printers. If the resin needs to be changed to the one that you want, ask a Lab Volunteer to help you.

- Choosing a Resin Type

- Go through each of these resin types to evaluate which material you will make your part out of. Once you have finished, you can send the file from the computer to the Formlabs printer

- Black/grey standard: the Standard Resins section of Choosing the Right Material.

- Pros: high detail, matte surfaces, good for small, intricate features.

- Cons: not particularly strong, stretchy, or flexible.

- Tough: Tough

- Pros: good for hard edges, snap fits, and high-stresses.

- Cons: bad for fine details and rigid prints, will not stretch as much as Durable.

- Durable: Durable

- Pros: low-friction, high impact strength, good for parts that are both rigid and flexible.

- Cons: bad for fine detail parts.

- Flexible: Flexible

- Pros: can simulate rubber when uncured, good for functional prototyping.

- Cons: bad for fine detail or applications when rigidity or hardness are required.

- See the respective links for each resin for in-depth descriptions of each resin's properties and suggested applications, or look at Choosing the Right Material for a shorter overview. Most resins do not handle high temperatures or constant loading well.

- Operating the Touchscreen

- You will be able to start your print using the touchscreen on the Form 3. If it is sleeping, just press the button and it should wake up.

- When it wakes up, you will likely see this screen. It displays the most recently prepared job and gives you the option to print now by pressing the blue button on the bottom right of the screen.

- There are two other buttons you can press on the left screen. The USB button will take you to the settings of the printer, so you will not need to go here. The checklist button brings a list of every job that has been uploaded to the printer, so you will want to be selecting this one to find your print. When you find your print, select "print now". The printer will make sure that you perform the appropriate setup before it starts printing, such as inserting the tank in the back of the printer and assuring that the build plate is cleared of other printed parts.

- The print will begin its process once you hit Print Now! A time estimate will be provided.

- Removing Prints

- Your part should now be finished! Follow these steps to clean it up.

- Finished prints

- Use a scraping tool to remove the print and any extra material from the build plate, taking care to not scratch the build plate. Go as carefully and as slowly as needed to prevent damaging the print.

- The build plate stand can be used for easier removal.

- Wash the print in the Form Wash.

- If the print is being cured, only remove support material after it has been run through the Form Cure.

- Supports should be clipped off, and any leftover support material can be sanded down if desired.

- Use a scraping tool to remove the print and any extra material from the build plate, taking care to not scratch the build plate. Go as carefully and as slowly as needed to prevent damaging the print.

- Failed prints

- Follow the same process for finished prints for removing.

- When a print fails, the build plate must be cleaned and run through the Wash before a new print can be started, as leftover residue from the failed print can cause subsequent prints to also fail. You will also need to check the resin tank for clumps as well as double check the model orientation. Don't forget to update the job log as well.

- Washing and Curing Prints

- See the Form Wash and Cure page.

- Changing Resin

- If the Formlabs Printer resin tray does not contain the resin you want, allow Lab volunteers to provide the desired resin.

- Remove, clean, and replace the build plate.

- Pull lever holding build plate in place up, allowing the build plate to be removed.

- Place the build plate on the holding rack in the Form Wash. Run the build plate through the Wash to remove resin. For the build plate, the Wash should be set to 10 minutes.

- Let the build plate air dry before replacing, secure by flipping lever down.

- Remove and replace resin tank and wiper.

- Firmly pull tank back towards the touch screen until it pops loose of the printer.

- Place the tank in the appropriately labeled tank storage container in the cabinet under the printer.

- Remove the desired tank from the storage container and place the container back in the cabinet.

- Slot the new resin tank into place in the printer by putting it in and sliding it towards the back of the machine.

- Use a scraping tool to dredge bottom of new resin tank for any hardened resin or loose bits of material, remove any found bits.

- Be sure to clean up any resin that spills during this process.

- Remove and replace the resin cartridge in the back of the printer.

- Close the lid of the cartridge if it's open.

- Pull cartridge out of the printer.

- Wipe dry the resin drip on the bottom of the cartridge, then store.

- Insert new resin cartridge, of the same resin as the tank.

- Open lid on resin cartridge before starting a print, and close after.

Safety

The most dangerous part of using the Form 3 is taking the part off of the build plate. The scraping tool could hurt your little fingers, so make sure you do not hit them. Also, the alcohol used to clean the print is not for drinking purposes. It is both against the lifestyle contract and very harmful to you if you drink it, so do not do it.

Approved Resins

Certification

Troubleshooting

If a print fails, the most likely cause is contamination of the resin. Before proceeding, see the procedure for Failed Prints. Contamination of the resin involves leftover material on the build plate, or particulates in the resin tank. Before attempting a new print, thoroughly clean the build plate, and dredge the resin tank for any loose particles. Another cause is incorrect orientation of the print. Check the print file in question, and ensure it has been canted accordingly to prevent the de-laminating process from removing the print from the build plate. Make sure to also update the job log.

Old resin and resin tanks can also present issues. Don't ever mix resin types. If a resin tanks is particularly cloudy on the bottom, the laser will be prevented from being able to penetrate the tank, and cause adhesion issues for the print. Resin can also go bad after sitting for long periods of time or being used heavily. This can be evidenced by discoloration of the resin or separation of the resin into unmixed layers.

Maintenance

General maintenance

- Dredging: Every few prints the resin tank should be checked and dredged with a scraping tool to search for any hardened resin or loose bits of material, as well as when resin tanks are switched out, and when a print fails. Remove any found bits. Dredging is done by sweeping a scraping tool back and forth across the bottom of the resin tank, essentially mixing up the resin to stir up any loose bits. Take care while dredging to not scrape the tank. See a resin's particular page on the Formlabs website for additional cleaning instruction. If the tank is not cleanable, switch out the resin tank. If the problem persists, it's possible the resin cartridge needs to be switched out as well.

- Alcohol in the Form Wash must be changed once a certain threshold of washed-off resin enters the tank. See the Form Wash and Cure page for details.

- Old resin and resin tanks will occasionally need to be changed out

- Form 2 Sources and Help

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Dredging | Every few prints | Lab Volunteer |

| Changing Alcohol | Once a certain threshold of washed-off resin enters the tank. See the Form Wash and Cure page for details. | Lab Volunteer |

| General Cleaning | Before and after each use. Reset The Space! | Student |

Resources

Link to shop Equipment page