Difference between revisions of "Sheet Metal Shear"

| (79 intermediate revisions by 7 users not shown) | |||

| Line 2: | Line 2: | ||

|Is equipment=True | |Is equipment=True | ||

|Is sheet metal equipment=True | |Is sheet metal equipment=True | ||

| − | |Has make= | + | |Has name={{PAGENAME}} |

| − | |Has model= | + | |Has make=Peck, Stow & Wilcox Co. |

| + | |Has model=G-52 | ||

| + | |Has serial number=H-209 | ||

| + | |Has life expectancy= | ||

| + | |Has year of manufacture or purchase= | ||

| + | |Has replacement cost= | ||

|Is located in facility= Machine Shop | |Is located in facility= Machine Shop | ||

|Is used in domain=Metal | |Is used in domain=Metal | ||

|Has function=Sheet Metal Shear | |Has function=Sheet Metal Shear | ||

| − | |Has | + | |Has certification=https://georgefox.instructure.com/courses/1307 |

| − | |Has icon=File: | + | |Has icon=File: Sheet_metal_shearIcon.png |

|Has icondesc=Sheet Metal Shear icon | |Has icondesc=Sheet Metal Shear icon | ||

| − | |Has image=File: | + | |Has image=File:Pexto_G-52.JPG |

| − | |Has imagedesc= | + | |Has imagedesc=Sheet Metal Shear |

| − | |Has description= | + | |Has description=Sheet Metal Shear |

| − | + | |Has ace=Brady Pfeiffer;bpfeiffer21@georgefox.edu | |

| − | + | }} | |

| − | = | + | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|140px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]] |

| − | + | [[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|300px|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]] | |

| − | |||

| + | Make: {{#show: {{PAGENAME}} |?Has make}} | ||

| − | == Training == | + | Model: {{#show: {{PAGENAME}} |?Has model}} |

| − | === | + | |

| − | + | Serial Number: {{#show: {{PAGENAME}} |?Has serial number}} | |

| − | + | ||

| − | # | + | Ace: {{#show: {{PAGENAME}} |?Has ace.Has name}} ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). |

| − | # | + | |

| − | == Safety == | + | Location: {{#show: {{PAGENAME}} |?Is located in facility}} |

| − | + | ||

| − | + | ||

| − | + | ==Description== | |

| − | == | + | |

| + | The shear is used for making straight cuts in sheet metal as well as other materials. The shearing blade is powered by applying force to the foot pedal located on the lower front of the machine. To prevent damage to yourself and or the machine make sure you obey the following rules: | ||

| + | * Maximum aluminum material thickness you can cut with this machine is .07" x full width. | ||

| + | * Maximum mild steel thickness you can cut with this machine is .06" x 12" wide | ||

| + | * Maximum stainless steel thickness you can cut with this machine is .04" x 12" (ask before cutting stainless steel) | ||

| + | * NEVER attempt to cut round stock or wire on the shear. | ||

| + | * Plastics can be cut up to 1/8" thick x the blade width. | ||

| + | * Ask Justin or Nick G. prior to cutting any other materials. | ||

| + | * Always use the cam lock bar to hold material prior to cutting. | ||

| + | Here is an example of this piece of equipment being used. | ||

| + | |||

| + | {{#evu:https://www.youtube.com/watch?v=KFaqs6GGc0I}} | ||

| + | |||

| + | ==Documentation== | ||

| + | |||

| + | ====Terminology==== | ||

| + | |||

| + | *Foot Pedal: The bar located across the front of the machine used to activate the blade. | ||

| + | *Hold Down: A cam operated bar in front of the blade used to keep the material from moving during a cut. | ||

| + | *Hold Down Handles: The handles used to actuate hold down clamp. | ||

| + | |||

| + | [[Media:NO.G52.pdf|Sheet Metal Shear User Manual]] | ||

| + | |||

| + | ==Training== | ||

| + | ====Operation==== | ||

| + | |||

| + | The sheet metal shear is human powered. You will be pressing down on the foot pedal to move the blade that shears the material. The upper rail has two handles for clamping down your work prior to shearing.The manufacturer rates this shear for 16 gauge mild steel. It would be very difficult to cut a full width of material with this machine so we are limiting the width to 12 inches. It is recommended that you stick to thinner and smaller pieces of material when using the machine. This machine is not designed to cut round stock and it will ruin the blade. Keep body parts away from the blade at all times. Don't stick anything you wouldn't want cut off under the blade. This machine is not designed to cut round stock or hard materials and both of these will ruin the blade. Only place sheet metal on the shear to prevent other object getting under the blade. After making your cut the edge of the material will most likely be very sharp and need to be deburred. | ||

| + | |||

| + | ====Demonstration==== | ||

| + | |||

| + | For the demonstration you will need to show understanding of the machine use and setup. You will need to select an appropriate piece of material for the demonstration and make a safe cut. By placing a mark on the material you can demonstrate your ability to align the blade with the cut line. | ||

| + | |||

| + | ====General Procedure==== | ||

| + | |||

| + | #Find a piece of scrap material that is within the capacity of the machine. Don't waste large pieces of material. Choose a smaller piece preferably an inch or two wide. | ||

| + | #Draw a cut line on the material using a straight edge and a marker. | ||

| + | #Make sure the material hold down is up enough to slide your material under. | ||

| + | #Make sure the cutting side of the blade aligns with the mark on your material. | ||

| + | #Pull down on both hold down levers and lock the material in place. | ||

| + | #Depending on the width of cut and how much you weigh, you may need to place one or two feet on the foot pedal. | ||

| + | #Keep your hands away from the blade. You can hold onto the top hold down rail to steady yourself if needed. | ||

| + | #You may need to jump or press down on the foot pedal to get the material to shear. | ||

| + | #After the material is cut you will need to remove yourself from the foot pedal. | ||

| + | #Release the hold down levers and remove the material. | ||

| + | #Reset the space. | ||

| + | |||

| + | ==Safety== | ||

| + | *Fingers must be kept away from the blade at all times. Never place your hand or fingers near the blade. | ||

| + | *Sheet metal can be razor sharp. Always be aware of sharp edges and corners. It is recommended to use gloves when handling sheet metal. | ||

| + | *Make sure others keep away from the foot pedal. Keep toes/feet out from under the pedal when it comes down. | ||

| + | |||

| + | ==Certification== | ||

| + | Complete the <strong>Machine Shop - {{PAGENAME}} Module</strong> at the link below to gain access to the {{PAGENAME}}. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email <span style="color:blue">makerhub@georgefox.edu</span> if you have any questions. | ||

| + | |||

| + | [https://georgefox.instructure.com/enroll/GH36RT Maker Hub Canvas Course] | ||

| + | |||

| + | ==Troubleshooting== | ||

| + | If you weigh less than 150 pounds you may have problems getting the material to cut. Ask a supervisor for help if you have any issues. | ||

| + | |||

| + | ==Maintenance== | ||

| + | ====General maintenance==== | ||

| + | |||

| + | The machine should be oiled periodically by the tech. | ||

| + | |||

| + | ====Specific Maintenance Tasks==== | ||

| + | {| class="wikitable" | ||

| + | !Maintenance Procedure | ||

| + | !Frequency | ||

| + | !Done By | ||

| + | |- | ||

| + | |Oil Blade | ||

| + | |As needed | ||

| + | |Technician | ||

| + | |} | ||

Latest revision as of 14:08, 22 August 2024

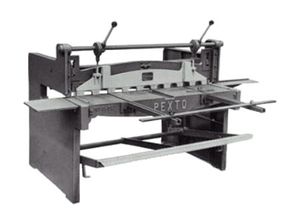

Make: Peck, Stow & Wilcox Co.

Model: G-52

Serial Number: H-209

Ace: Brady Pfeiffer (bpfeiffer21@georgefox.edu).

Location: Machine Shop

Description

The shear is used for making straight cuts in sheet metal as well as other materials. The shearing blade is powered by applying force to the foot pedal located on the lower front of the machine. To prevent damage to yourself and or the machine make sure you obey the following rules:

- Maximum aluminum material thickness you can cut with this machine is .07" x full width.

- Maximum mild steel thickness you can cut with this machine is .06" x 12" wide

- Maximum stainless steel thickness you can cut with this machine is .04" x 12" (ask before cutting stainless steel)

- NEVER attempt to cut round stock or wire on the shear.

- Plastics can be cut up to 1/8" thick x the blade width.

- Ask Justin or Nick G. prior to cutting any other materials.

- Always use the cam lock bar to hold material prior to cutting.

Here is an example of this piece of equipment being used.

Documentation

Terminology

- Foot Pedal: The bar located across the front of the machine used to activate the blade.

- Hold Down: A cam operated bar in front of the blade used to keep the material from moving during a cut.

- Hold Down Handles: The handles used to actuate hold down clamp.

Training

Operation

The sheet metal shear is human powered. You will be pressing down on the foot pedal to move the blade that shears the material. The upper rail has two handles for clamping down your work prior to shearing.The manufacturer rates this shear for 16 gauge mild steel. It would be very difficult to cut a full width of material with this machine so we are limiting the width to 12 inches. It is recommended that you stick to thinner and smaller pieces of material when using the machine. This machine is not designed to cut round stock and it will ruin the blade. Keep body parts away from the blade at all times. Don't stick anything you wouldn't want cut off under the blade. This machine is not designed to cut round stock or hard materials and both of these will ruin the blade. Only place sheet metal on the shear to prevent other object getting under the blade. After making your cut the edge of the material will most likely be very sharp and need to be deburred.

Demonstration

For the demonstration you will need to show understanding of the machine use and setup. You will need to select an appropriate piece of material for the demonstration and make a safe cut. By placing a mark on the material you can demonstrate your ability to align the blade with the cut line.

General Procedure

- Find a piece of scrap material that is within the capacity of the machine. Don't waste large pieces of material. Choose a smaller piece preferably an inch or two wide.

- Draw a cut line on the material using a straight edge and a marker.

- Make sure the material hold down is up enough to slide your material under.

- Make sure the cutting side of the blade aligns with the mark on your material.

- Pull down on both hold down levers and lock the material in place.

- Depending on the width of cut and how much you weigh, you may need to place one or two feet on the foot pedal.

- Keep your hands away from the blade. You can hold onto the top hold down rail to steady yourself if needed.

- You may need to jump or press down on the foot pedal to get the material to shear.

- After the material is cut you will need to remove yourself from the foot pedal.

- Release the hold down levers and remove the material.

- Reset the space.

Safety

- Fingers must be kept away from the blade at all times. Never place your hand or fingers near the blade.

- Sheet metal can be razor sharp. Always be aware of sharp edges and corners. It is recommended to use gloves when handling sheet metal.

- Make sure others keep away from the foot pedal. Keep toes/feet out from under the pedal when it comes down.

Certification

Complete the Machine Shop - Sheet Metal Shear Module at the link below to gain access to the Sheet Metal Shear. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email makerhub@georgefox.edu if you have any questions.

Troubleshooting

If you weigh less than 150 pounds you may have problems getting the material to cut. Ask a supervisor for help if you have any issues.

Maintenance

General maintenance

The machine should be oiled periodically by the tech.

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Oil Blade | As needed | Technician |