Difference between revisions of "Bending Brake"

| (4 intermediate revisions by 2 users not shown) | |||

| Line 16: | Line 16: | ||

|Has imagedesc=48 inch bending brake, 14 gauge | |Has imagedesc=48 inch bending brake, 14 gauge | ||

|Has description=48 inch bending brake, 14 gauge | |Has description=48 inch bending brake, 14 gauge | ||

| − | |Has ace= | + | |Has ace=Nathan Hayward;nhayward21@georgefox.edu |

}} | }} | ||

[[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|140px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]] | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|140px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]] | ||

| Line 30: | Line 30: | ||

Location: {{#show: {{PAGENAME}} |?Is located in facility}} | Location: {{#show: {{PAGENAME}} |?Is located in facility}} | ||

| + | |||

| + | ==Safety First== | ||

| + | [[File:Safety First HD2.png|left|150px]] | ||

| + | Here are some safety instructions for the {{PAGENAME}}. Remember... SAFETY FIRST!!! | ||

| + | * Always make sure your hands are out of the way of the fingers and all moving parts | ||

| + | * Be aware of your surroundings to ensure that you do not bump others with the counterweight. | ||

| + | * If bending a small piece of metal, place it in the center of the brake. | ||

| + | * Do not attempt to bend material thicker than 16 gauge. | ||

| + | * Only use sheet metal with the brake. Don't try to bend round material! | ||

| + | * You may not use the sheet metal machines without safety glasses!! (Should be obvious if you are following the rules of the shop) | ||

==Description== | ==Description== | ||

| Line 41: | Line 51: | ||

==Documentation== | ==Documentation== | ||

| − | + | [[Media:Chicago-hand-operated-bending-brakes-brochure.pdf|Bending Brake User Manual]] | |

====Terminology==== | ====Terminology==== | ||

| Line 72: | Line 82: | ||

#Put back any fingers if adjusted, and deburr if any rough edges are left. | #Put back any fingers if adjusted, and deburr if any rough edges are left. | ||

| − | == | + | ==Reset the Space== |

| − | + | [[File:Reset The Space HD2.png|left|150px]] | |

| − | + | Here is how you can reset the space for the {{PAGENAME}}. Remember to leave the space better than you found it!!! | |

| − | + | * If you removed or adjusted any fingers, put them back where they belong. | |

| − | + | * Reset all materials, scrap pieces go in the scrap bin. | |

| − | + | * Ensure that the Brake and surrounding area are clean. | |

| − | + | * Return any borrowed gloves or other equipment to their proper storage locations. | |

| − | |||

| − | |||

| − | |||

==Certification== | ==Certification== | ||

Revision as of 09:57, 25 May 2022

Make: Chicago Steel

Model: W31

Serial Number: 91016

Ace: Nathan Hayward (nhayward21@georgefox.edu).

Location: Machine Shop

Safety First

Here are some safety instructions for the Bending Brake. Remember... SAFETY FIRST!!!

- Always make sure your hands are out of the way of the fingers and all moving parts

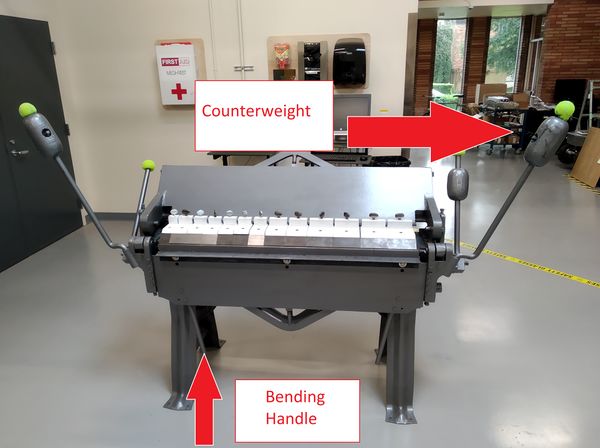

- Be aware of your surroundings to ensure that you do not bump others with the counterweight.

- If bending a small piece of metal, place it in the center of the brake.

- Do not attempt to bend material thicker than 16 gauge.

- Only use sheet metal with the brake. Don't try to bend round material!

- You may not use the sheet metal machines without safety glasses!! (Should be obvious if you are following the rules of the shop)

Description

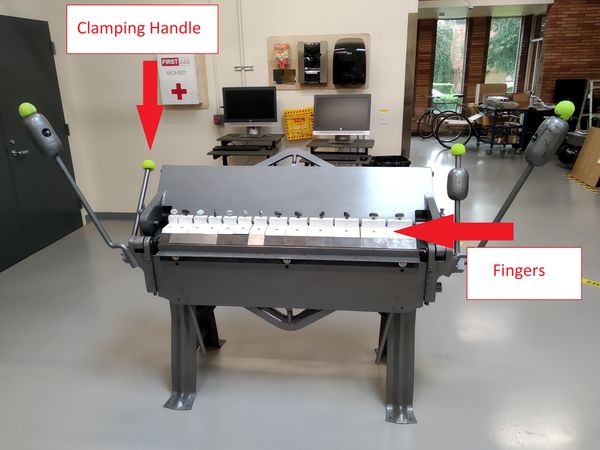

A bending brake is a metalworking machine that allows the bending of sheet metal. The brake is a Chicago W31 steel box and pan brake. The max material thickness capacity of this machine is 16 gauge mild steel. In a box-and-pan brake (also known as a finger brake), the clamping bar includes several removable blocks, which may be removed and rearranged to permit bending of restricted areas of a piece of sheet metal or of already partially formed pieces. After bending, a box or pan form is then completed by screw, solder, weld, rivet, or other metal fixing process.

Here is an example of this piece of equipment being used.

Documentation

Terminology

- Bending Handle-

- Clamping Handle-

Parts of the Machine

Training

Operation

Insert Text

Demonstration

To demonstrate competency on the Bending brake you will be required to bend a piece of sheet metal to a 90 degree angle.

General Procedure

Bending Steps

- Ensure that your sheet metal is thinner or equivalent to 16-gauge sheet metal, and ensure that it is less than 48" in width.

- If making a bend for a box or a pan, adjust the fingers so that the equivalent width of the fingers is just shorter than your sheet metal.

- Adjust the clamping force and the clamping handle to allow room to insert your work piece.

- Insert your work piece to the line you want to bend, centered in the brake, and clamp your piece securely.

- Pull up on the bending handle of the leaf slowly until your piece is bent to the desired angle, and slowly lower the leaf.

- If the piece does not bend straight, unclamp the handle on the over-bent side and adjust the top leaf.

- Adjust the clamp handle, and remove your piece.

- Put back any fingers if adjusted, and deburr if any rough edges are left.

Reset the Space

Here is how you can reset the space for the Bending Brake. Remember to leave the space better than you found it!!!

- If you removed or adjusted any fingers, put them back where they belong.

- Reset all materials, scrap pieces go in the scrap bin.

- Ensure that the Brake and surrounding area are clean.

- Return any borrowed gloves or other equipment to their proper storage locations.

Certification

Troubleshooting

Maintenance

General maintenance

The machine needs to be cleaned and pivot points should be lubricated.

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Oil Surfaces | As Needed | Technician |