Difference between revisions of "Vacuum Former"

| (36 intermediate revisions by 4 users not shown) | |||

| Line 4: | Line 4: | ||

|Is used in domain= | |Is used in domain= | ||

|Has name={{PAGENAME}} | |Has name={{PAGENAME}} | ||

| + | |Has make=Formech | ||

| + | |Has model=508DT | ||

| + | |Has serial number=2728 | ||

| + | |Has life expectancy= | ||

| + | |Has year of manufacture or purchase= | ||

| + | |Has replacement cost= | ||

|Has icon=File:Vacuum Former.png | |Has icon=File:Vacuum Former.png | ||

|Has icondesc= | |Has icondesc= | ||

| Line 10: | Line 16: | ||

|Has imagedesc= | |Has imagedesc= | ||

|Has description= | |Has description= | ||

| − | |Has certification= | + | |Has certification=https://georgefox.instructure.com/courses/1305 |

| − | + | |Has ace=Needed;Makerhub@georgefox.edu | |

| − | |||

| − | |Has ace= | ||

}} | }} | ||

| − | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}| | + | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|140px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]] |

[[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|300px|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]] | [[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|300px|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]] | ||

Make: {{#show: {{PAGENAME}} |?Has make}} | Make: {{#show: {{PAGENAME}} |?Has make}} | ||

| − | Model: {{#show: {{PAGENAME}} |?Has model}} | + | Model: {{#show: {{PAGENAME}} |?Has model}} |

| + | |||

| + | Serial Number: {{#show: {{PAGENAME}} |?Has serial number}} | ||

Ace: {{#show: {{PAGENAME}} |?Has ace.Has name}} ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). | Ace: {{#show: {{PAGENAME}} |?Has ace.Has name}} ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). | ||

Location: {{#show: {{PAGENAME}} |?Is located in facility}} | Location: {{#show: {{PAGENAME}} |?Is located in facility}} | ||

| + | |||

| + | |||

| + | __TOC__ | ||

==Description== | ==Description== | ||

| − | The Formech 508DT Vacuum Former is a plastic molding machine that utilizes a vacuum to stretch | + | The Formech 508DT Vacuum Former is a plastic molding machine that utilizes heat and a vacuum to stretch heated plastic over a mold. The vacuum former is great for thin plastic molds, although there are some limitations on the shape and size. The max dimensions for the mold are 17”x19” with a depth of 7.3". The max thickness for the plastic sheet is 0.25" Molds can be made from many types of materials. It's fairly common to see molds made from wood. Molds need to have some draft so they can be removed from the plastic. |

| + | |||

| Line 40: | Line 50: | ||

* '''Table-''' The bed that the mold rests on. | * '''Table-''' The bed that the mold rests on. | ||

| − | * '''Clamp Frame-''' | + | * '''Clamp Frame-''' The metal bars that captivate the plastic sheet as its heated and stretched over the mold. |

* '''Toggle Clamp Screws-''' | * '''Toggle Clamp Screws-''' | ||

| + | *'''Draft Angle-''' The wall angle of a mold. This helps in removing the plastic off the mold. | ||

Knowing what the different buttons in the touchscreen operation mean is important in operating the vacuum former. The three primary ones are heat , vacuum , and release . For a full list, refer to the manual. | Knowing what the different buttons in the touchscreen operation mean is important in operating the vacuum former. The three primary ones are heat , vacuum , and release . For a full list, refer to the manual. | ||

| − | + | [[Media:Manual-508DT.pdf|Vacuum Former User Manual]] | |

| − | |||

| − | + | [[Media:Vacuum Forming Guide 200715.pdf|Vacuum Forming Guide]] | |

| − | ==== | + | ==Training== |

| + | ====Operation==== | ||

| − | + | The vacuum former can mold up to a 19"x17" square and to a depth of 7.3". | |

| − | + | Molds must slant outwardly slightly to ensure that they can be popped out of the plastic after molding is finished. | |

| − | + | ====Demonstration==== | |

| − | + | Text here | |

| − | + | ====Operation==== | |

| − | |||

| − | + | [[File:Formech_Controls.JPG|none|thumb|600x600px]] | |

| − | + | == Operation == | |

| − | + | * Place a mold into the tray and lower it. | |

| − | + | * Mold cannot be concave and must slant outwards slightly or it will not be removable from the plastic. | |

| − | + | * Place plastic into the clamps ensuring it completely covers the white seals. | |

| − | + | * Turn on the heaters. They should take about 15 minutes to warm up. | |

| − | + | * Lift the table. | |

| − | + | * Turn on the vacuum. | |

| − | + | * Let the plastic cool, then hit the release button. | |

| − | + | * Lower the table to remove the plastic. | |

| − | + | * Reset the table. | |

| − | |||

==Safety== | ==Safety== | ||

| − | * | + | * Parts of the machine can reach over 300 degrees C. Don't touch the heater or heat shield surrounding the heater. |

| − | * Never put your hand in a position | + | * Never put your hand in a position it could be pinched by the molding frame. |

| − | * | + | * The formed plastic is very hot and sticky. It could stick to you and continue to burn if you touch it. |

| − | + | * Some types of plastics could give off toxic fumes when heated. Check the SDS before working with materials you are unfamiliar with. | |

| − | |||

| − | * | ||

==Certification== | ==Certification== | ||

| − | [https:// | + | [https://georgefox.instructure.com/courses/1305 Canvas Quiz] |

==Troubleshooting== | ==Troubleshooting== | ||

| − | + | Make sure to put draft on your form to prevent sticking. | |

| − | + | If the plastic is not hot enough it won't pull down over the form. | |

==Maintenance== | ==Maintenance== | ||

====General maintenance==== | ====General maintenance==== | ||

| − | |||

| − | |||

| − | |||

| − | |||

====Specific Maintenance Tasks==== | ====Specific Maintenance Tasks==== | ||

| Line 105: | Line 108: | ||

!Done By | !Done By | ||

|- | |- | ||

| − | | | + | |Inspect |

|As Needed | |As Needed | ||

|Ace/Tech | |Ace/Tech | ||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Revision as of 13:01, 23 January 2023

Make: Formech

Model: 508DT

Serial Number: 2728

Ace: Needed (Makerhub@georgefox.edu).

Location: The Vault

Description

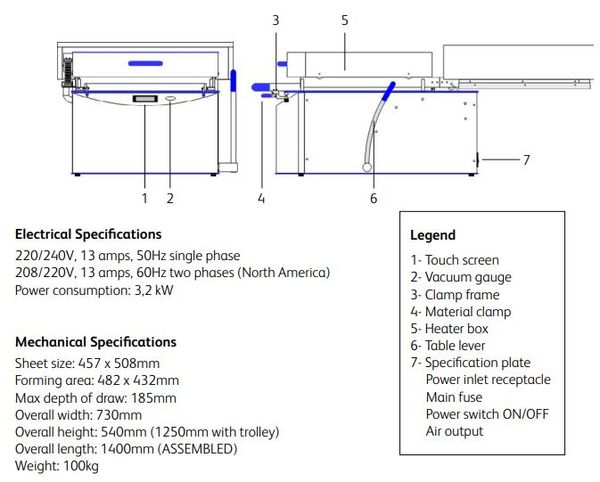

The Formech 508DT Vacuum Former is a plastic molding machine that utilizes heat and a vacuum to stretch heated plastic over a mold. The vacuum former is great for thin plastic molds, although there are some limitations on the shape and size. The max dimensions for the mold are 17”x19” with a depth of 7.3". The max thickness for the plastic sheet is 0.25" Molds can be made from many types of materials. It's fairly common to see molds made from wood. Molds need to have some draft so they can be removed from the plastic.

Here is an example of this piece of equipment being used.

Documentation

Terminology

- Table- The bed that the mold rests on.

- Clamp Frame- The metal bars that captivate the plastic sheet as its heated and stretched over the mold.

- Toggle Clamp Screws-

- Draft Angle- The wall angle of a mold. This helps in removing the plastic off the mold.

Knowing what the different buttons in the touchscreen operation mean is important in operating the vacuum former. The three primary ones are heat , vacuum , and release . For a full list, refer to the manual.

Training

Operation

The vacuum former can mold up to a 19"x17" square and to a depth of 7.3".

Molds must slant outwardly slightly to ensure that they can be popped out of the plastic after molding is finished.

Demonstration

Text here

Operation

Operation

- Place a mold into the tray and lower it.

- Mold cannot be concave and must slant outwards slightly or it will not be removable from the plastic.

- Place plastic into the clamps ensuring it completely covers the white seals.

- Turn on the heaters. They should take about 15 minutes to warm up.

- Lift the table.

- Turn on the vacuum.

- Let the plastic cool, then hit the release button.

- Lower the table to remove the plastic.

- Reset the table.

Safety

- Parts of the machine can reach over 300 degrees C. Don't touch the heater or heat shield surrounding the heater.

- Never put your hand in a position it could be pinched by the molding frame.

- The formed plastic is very hot and sticky. It could stick to you and continue to burn if you touch it.

- Some types of plastics could give off toxic fumes when heated. Check the SDS before working with materials you are unfamiliar with.

Certification

Troubleshooting

Make sure to put draft on your form to prevent sticking. If the plastic is not hot enough it won't pull down over the form.

Maintenance

General maintenance

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Inspect | As Needed | Ace/Tech |