Difference between revisions of "Sheet Metal Shear"

Jump to navigation

Jump to search

| Line 15: | Line 15: | ||

|Has ace=Noah Bloomquist;nbloomquist17@georgefox.edu | |Has ace=Noah Bloomquist;nbloomquist17@georgefox.edu | ||

}} | }} | ||

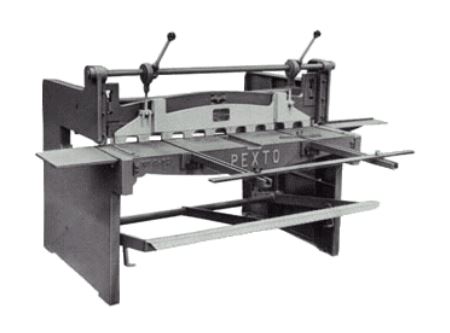

| − | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|100px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]][[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]]The shear in the shop is the Pexto G-52 Foot Squaring Shear. Squaring shears, like the one shown to the right, are used to cut sheet metal to a usable size. This shear is foot operated and can cut stock that is a maximum of 52 inches in width and 16-gauge in thickness. | + | [[{{#show: {{FULLPAGENAME}}|?Has icon|link=none}}|100px|left|top|{{#show: {{FULLPAGENAME}}|?Has icondesc}}]][[{{#show: {{FULLPAGENAME}}|?Has image|link=none}}|thumb|upright=1.5|{{#show: {{FULLPAGENAME}}|?Has imagedesc}}]]The shear in the shop is the Pexto G-52 Foot Squaring Shear. Squaring shears, like the one shown to the right, are used to cut sheet metal to a usable size by applying a shearing force with two opposing blades. This shear is foot operated and can cut stock that is a maximum of 52 inches in width and 16-gauge in thickness. |

The current Ace of the {{PAGENAME}} is '''{{#show: {{PAGENAME}} |?Has ace.Has name}}''' ({{#show: {{PAGENAME}} |?Has ace.Has email address}}).<br /> | The current Ace of the {{PAGENAME}} is '''{{#show: {{PAGENAME}} |?Has ace.Has name}}''' ({{#show: {{PAGENAME}} |?Has ace.Has email address}}).<br /> | ||

Revision as of 18:25, 15 March 2019

The shear in the shop is the Pexto G-52 Foot Squaring Shear. Squaring shears, like the one shown to the right, are used to cut sheet metal to a usable size by applying a shearing force with two opposing blades. This shear is foot operated and can cut stock that is a maximum of 52 inches in width and 16-gauge in thickness.

The current Ace of the Sheet Metal Shear is Brady Pfeiffer (bpfeiffer21@georgefox.edu).

Resources

Training

Shearing Steps

- Make sure the table and floor are clear prior to shearing.

- Mark your piece, place it on the right side of the table, and slide your piece in till your cut line is directly under the blade and against the side guard. Make sure your fingers stay out of the clampdown or you can accidentally crush your fingers if not careful.

- With your fingers holding the piece, use the yellow handle to clamp down on your piece. If the piece is extremely long, ask for assistance.

- Press down on the pedal with your foot until the shear completely cuts your piece. Before the blade engages the piece, make sure that your piece if held securely by the clampdown.

- Collect all of your pieces and deburr.

Safety

- Never ever put your fingers in the path of the blade or under the clampdown unless you want your fingers cut off!!

- Don't put your second foot under the pedal as you could smash your toes.

- Never leave anything on the table of the shear.

- After shearing, use caution in handling your pieces as they are most likely sharp. Make sure you deburr.