MIG Welder

Make: Miller Electric

Model: Millermatic 210

Ace: Wyatt Bertis (wbertis22@georgefox.edu).

Location: Welding Shop

Description

The Millermatic 210 is a wire feed metal inert gas (MIG) welder that is meant for light industrial use. Metal inert gas is a welding process in which an electric arc forms between a consumable MIG wire electrode and the base metal, which heats the base metal, causing them to melt and join. Along with the wire electrode, a shielding gas feeds through the welding torch, which shields the process from contaminants in the air. This is the easiest and most common type of welding which makes it perfect for those learning to weld. It uses 72/25 CO2 and Argon gas mixture to shield the molten weld from oxygen. If the weld pool is exposed to oxygen, it can create a handful of problems such as porosity and excessive spatter in the bead. This welder is capable of welding carbon steel as well as stainless steel. Before completing the training on this machine you must complete the Virtual Reality Welding Station training and spend some time practicing with it to get a feel for the welding process. Below is a short video explaining MIG welding.

Documentation

Terminology

- MIG Welding - Metal inert gas is a welding process in which an electric arc forms between a consumable MIG wire electrode and the base metal, which heats the base metal, causing them to melt and join. Along with the wire electrode, a shielding gas feeds through the welding torch, which shields the process from contaminants in the air.

- Weld Metal/Electrode - The metal added to the base metal to create a weld.

- Torch - The piece that is held while welding and feeds the weld metal into the base metal.

- Base metal - The metal pieces that are being joined together.

- Coupons - Small pieces of metal used to practice welding.

Training

Overview

Insert Text

Demonstration

Insert text

General Procedure

Prior to Welding

- Place the fume hood over the area you will be welding and make sure it is on. The power switch is located on the wall next to the door and light switch.

- Attach the ground clamp to the metal bench your workpiece will be on. Ideally, place the ground clamp to the base metal itself to create the smoothest path for the electrical current.

- Ensure the workpiece is touching the conductive surface of the table

- Ensure the adjusting screw on the tank regulator is loose (Do not unscrew all the way)

- Open cylinder valve all the way

- Turn the adjusting screw (clockwise) to increase pressure to 15 CFH.

- Identify material type and thickness that is going to be welded

- Refer to MIG welding chart for specified adjustments, specific to your application

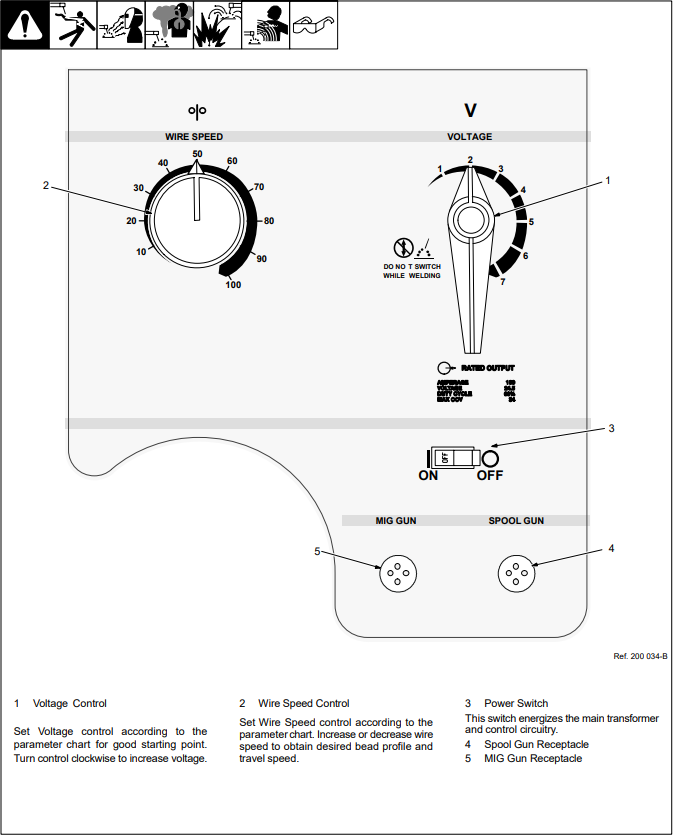

- Turn on the welder and adjust wire speed and voltage. Refer to the image below to see the controls for doing this.

- Ensure you are wearing all necessary protective gear

- Ensure the welding torch has proper amount of wire protruding from tip (about ¼ inch) If too long, trim excess with the welding pliers.

- Weld!

After Welding

- Close gas cylinder valve

- Bleed remaining gas by depressing trigger until regulator drops to 0

- Back out adjusting screw on regulator (Do Not unscrew all the way)

- Turn off the welder

- Remove ground clamp

Safety

- Touching live electrical parts can cause fatal shocks or severe burns. The electrode and work circuit is electrically live whenever the output is on. The input power circuit and machine internal circuits are also live when power is on. In semiautomatic or automatic wire welding, the wire, wire reel, drive roll housing, and all metal parts touching the welding wire are electrically live.

- Don’t weld lead, zinc, copper, cadmium, stainless, or beryllium. Welding these materials can be harmful if not equipped with proper safety gear and training.

- Don’t weld in wet gear or standing water because this could create a new path for the electrical current to travel and cause a severe electrical shock.

- Always turn gas and the welder off when you are done in the welding shop to ensure there are no leaks that could cause asphyxiation (suffocating from lack of oxygen).

- Never weld without a welding helmet. Arc rays from the welding process produce intense visible and invisible (ultraviolet and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

- Never weld without gloves. Gloves protect your hands from the heat as well as the arc rays.

- Don't weld with the vent hood off. Welding produces fumes and gases. Breathing these fumes and gases can be hazardous to your health. Asphyxiation can also occur due to the confined nature of the welding shop and the use of welding gasses.

- Always weld with the door open to lower the risk of asphyxiation.

- Don't weld with the gas off. This can damage the machine.

- Don’t unscrew valve adjusting screw all the way out. This could damage the valve.

Certification

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |