Difference between revisions of "Formlabs 3D Printer"

Jump to navigation

Jump to search

| Line 57: | Line 57: | ||

[[Form Wash and Cure]] | [[Form Wash and Cure]] | ||

| − | Link to shop [[Equipment]] page<br \><br \><br \><br \><br \> | + | Link to shop [[Equipment]] page<br \> |

| + | |||

| + | Common errors, how to fix | ||

| + | |||

| + | More in depth to resin changing | ||

| + | |||

| + | Why choose form printer/ why choose resin type<br \><br \><br \><br \> | ||

<references /> | <references /> | ||

Revision as of 15:00, 22 October 2018

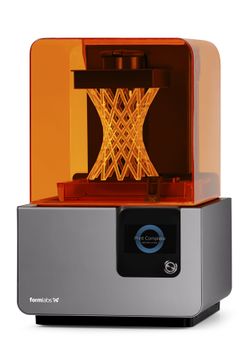

The Form 2 is Formlab's 3rd generation printer boasting a whole range of new features including a new peeling mechanism, heated tank, touchscreen display, wireless controls and an automated resin system. The resulting prints that come off of the Form 2 have consistently been among the highest quality objects to come off of any desktop 3D printer. This machine is best used with the Form Wash and Cure [1]

Documentation

Training

SLA Printing

- The Form 2 is an SLA Printer. Stereolithography, SLA, is a part of the manufacturing technology of vat polymerization. This means a light source (laser) is used to cure liquid resin into a hard plastic.

- The Form 2 utilizes the Upside Down or Inverted orientation.

- The resin tank has a clear bottom with a surface the resin will not stick to. This allows the resin to cure against the bottom of the tank.

- The build platform is lowered into the resin until it is hovering above the bottom surface of the tank, as far away as the height of the layer to be constructed.

- The laser is directed through the bottom of the tank and cures a layer of resin onto the build platform. Then, the resin tank slides over and the build platform raises. The wiper will then sweep across the tank to circulate the resin.

- The build platform will lower again, and the process will be repeated until the print is completed.

- Due to friction caused by de-laminating every layer, every part should be canted in its orientation. This means the part should be angled to reduce the cross sectional area needing to be shifted to de-laminate each layer. This de-lamination also causes the Form 2 to be the Prototype Lab's slowest 3D printer.

- Once a part is finished on the Form 2, it must be removed off of the build plate. Try to avoid scraping the build plate when removing parts. Any excess resin must be washed off using the Form Wash, the part must be air dried so that any isopropyl alcohol from the Wash has evaporated, the part should be cured in the Form Cure, and supports should be clipped off. Any remaining support marks can be sanded off if so desired.

- Extra information on SLA Printing can be found here.

Changing Resin

- Remove the build plate, run it through the Form Wash to remove resin, then let air dry before replacing.

- Firmly pull wiper back until it's out of its slot and loose in the resin tank. Leave the wiper in the resin tank, each tank has its own wiper.

- Firmly pull tank back until it pops loose of the printer, put the appropriate lid on the resin tank, and store with wiper in tank. Be sure to wipe up any resin that spills during the removal process.

- Close lid of resin cartridge in back of printer, remove, and store.

- Slot in the new resin cartridge, tank, and wiper of the desired resin.

- Use a scraping tool to dredge bottom of new resin tank for any hardened resin or loose bits of material, remove any found bits.

Maintenance

- Every few prints the resin tank should be dredged with a scraping tool to search for any hardened resin or loose bits of material, and when resin tanks are switched out. Remove any found bits.

Resources

Link to shop Equipment page

Common errors, how to fix

More in depth to resin changing

Why choose form printer/ why choose resin type