Foam Cutter

Make: Proxxon

Model: Thermocut 12E & 115E

Ace: Needed (Makerhub@georgefox.edu).

Location: The Hub

Description

The PROXXON THERMOCUT allows you to cut polystyrene (Styrofoam) in a clean and safe way without frayed edges or particulation. This foam cutter is deal for architects, designers, decorators, artists, and teachers. Examples include building architectural models, classic model railroads, plane and boat items, and numerous decorative items.

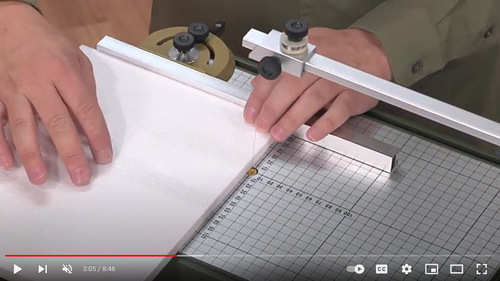

The large table with 15 11/32" x 11" (390 x 280mm) ensures smooth and easy movement of the workpiece. The printed grid and protractor assist with division and cutting. The solid aluminum overarm has a 13 3/4" (350mm) throat and offers 5 1/2" (140mm) in height. The holder and wire coil (one spool of wire 98ft., 0.008" diameter is included) may be shifted and adjusted along the overarm to enable miter cutting. An LED indicates operation and thus reminds you not to touch the hot wire to prevent burnt fingers (the wire heats to maximum in less than 1 second).

Note: The correct temperature, being material and thickness dependent, is learned from experience. Profiles are ideally cut at lower temperatures and while applying less cutting force.

Technical data:

Cutting wire temperature: 210 - 390 °F (100 - 200 °C) Transformer secondary max: 10V at 1.0A Volts: 110 - 120V AC, 60 Hz Weight: 6.6 lb (3kg)

Here is an example of the table in use. (Link takes you to YouTube - embedding not allowed for this video??)

This is Proxxon's video for the hand-held cutter.

This is Proxxon's video for the table-top cutter.

Documentation

Terminology

There are two types of polystyrene foam best suited for processing with the Hot wire foam cutters and Hot knife cutters: extruded polystyrene (XPS foam), and expanded polystyrene (EPS foam). Although both types of insulation are comprised of polystyrene, the two types of manufacturing processes produce finished products with very different performance properties. XPS is manufactured in a continuous extrusion process that produces a homogeneous closed cell cross-section, whereas EPS is manufactured by expanding spherical beads in a mold, using heat and pressure to fuse the beads together.

Some people like to use hot wire tools to cut nylon and polyethylene rope because it singes and seals the ends.

User Manual

Training

Operation

A 0.2mm wire is heated using a safe 10V source, and this heated wire cuts through the polystyrene, melting it and providing a clean cut. By varying the amount of voltage on the wire (and thus current), the wire temperature can be varied between 100℃ - 200℃ (212℉ - 392℉).

Installing the cutting wire

- Switch off the device.

- Carefully unwind the cutting wire approx. 8’’ (20 cm).

- Open the lower wire guide by turning the knurled screw 4 (Fig. 1).

- Thread the wire approx. 2’’ (5 cm) into the lower wire guide.

- Clamp the wire by turning the knurled screw 4.

- Push the overarm 5 lightly downwards with your left hand, thread the wire through the guide slot 10 and fasten the wire spool 6 so that the wire is slightly tensioned.

- Release the arm. The wire is tensioned by the spring force of the arm.

- Check that the wire is a right angle with work surface. Adjust, if necessary by sliding the spool carrier 8 or by bending the clamp.

- Connect the mains plug. Your device is now ready for use.

Cutting

- Switch on the device with the switch 1(Fig. 1).

Note: It is normal that the wire extends somewhat after being heated for the first time. Stretch the wire slightly by the first heating and tension it again. The wire will now retain its length.

- Adjust the temperature with the regulator 2. The table on the front of the device serves

as a guide. The best way to find the ideal temperature is to try different temperatures yourself. For simple, straightforward cuts you use a high temperature, for complicated shapes a lower temperature. Please note that too high temperatures will cause untidy edges.

- Now move the workpiece through the wire with a light pressure and even speed. Be aware that too high pressure in the direction of the cut when cutting complicated shapes will tend to bend the wire.

Demonstration

Insert text

General Procedure

“Small sections of long profiles can best be cut by laying a waste piece 1 (Fig. 6) between the stop and the work piece and then cutting against the stop. The cutting wire then cuts into the waste piece and the edges remain clean.”

If you are gluing foam together, cut the foam before the glue dries. The foam cutters will not work well through dried glue.

Here are a few good videos to watch if you are building scenery with foam.

Safety

Clearly, getting burned by the hot wire is a safety concern. Don’t touch the hot wire. However, a much greater risk is the potential for dangerous fumes when cutting foams - especially foams other than polystyrene. It is very important that you verify that any other foams are safe to be cut.,

- Provide good ventilation, when using the device.

- Observe the material suppliers safety instructions when cutting.

- The cutting wire is hot. Risk of skin burn!

- Do not use the device near curtains or other combustible materials.

- Do not leave the device unattended when it is switched on.

- Only use the supplied cutting wire or original PROXXON replacement wire, otherwise the transformer can become overloaded.

- Switch off the device after use.

Polyisocyanurate foam should not be cut with hot wire tools. It needs a ton of heat, gives off toxic fumes, and leaves a lot of melted plastic wherever it is cut. We recommend that the polyisocyanurate foams only be cut with a blade or saw.

You can not cut through the spongy polyurethane foams used for upholstery. It beads off on the hot wire and gives off toxic fumes.

Certification

Troubleshooting

Maintenance

General maintenance

Insert text

Specific Maintenance Tasks

| Maintenance Procedure | Frequency | Done By |

|---|---|---|

| Sample | Sample | Sample |