Dimension 3D Printer

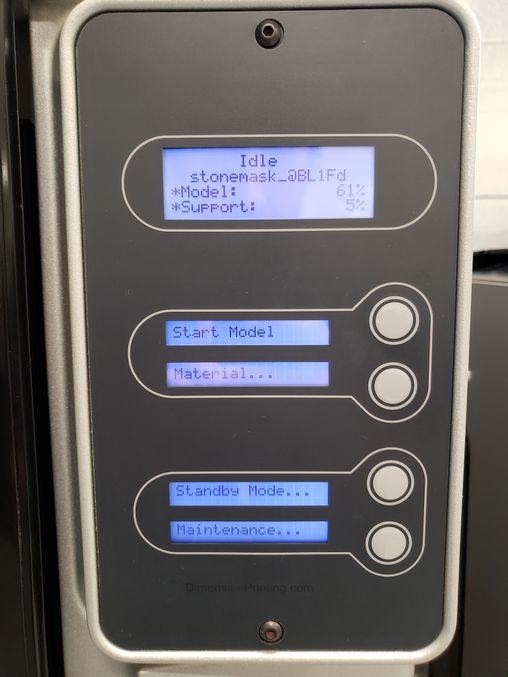

Dimension is designed with ultimate simplicity in mind. The system enables you to build parts quickly, even if you’ve never used a 3D printer before. Its display panel prompts you to press a few keys to get you modeling quickly.

The system models with ABS plastic, so modeled parts are strong and durable. ABS also ensures you’ll be able to drill, tap, sand, and paint your creations. With the speed and convenience of Breakaway Support Technology (BST) or Soluble Support Technology (SST), your completed parts are quickly available for review and test. [1].

Documentation

Training

GrabCAD Print

GrabCAD Print is the software that both the Dimension and F370 use, and allows you to easily orient and view the part you want to model. Both printers are web based, which allows you to start the print from the one of the lab's computers.

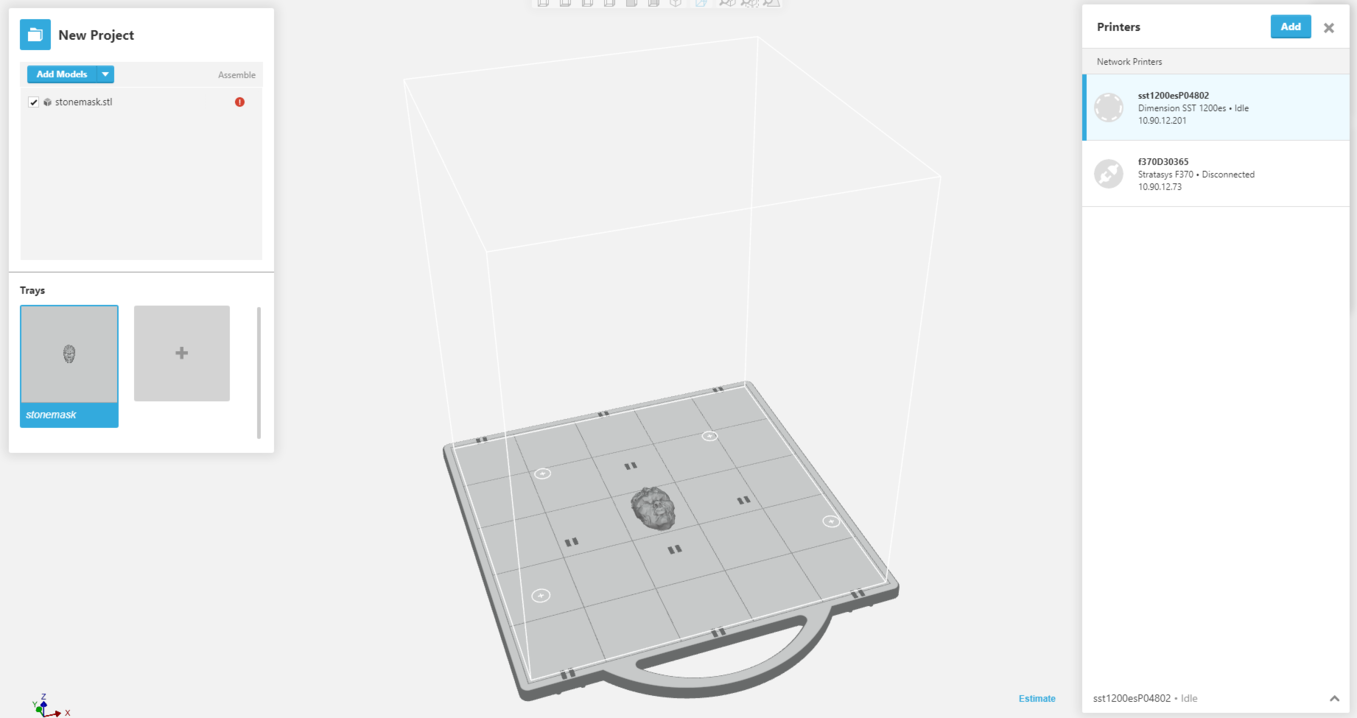

On Opening GrabCAD, make sure that you select the printer you want to use for the part you want to print, the volunteers in the lab can help you determine which printer would work best. The menu the the right of the image shows the printer options, make sure you select the correct printer, in this case it is the Dimension. After ensuring you have the software correctly set up, open your file and place it on the build plate, Note: your file has to be in STL format to work with any printing software. The build plate is correctly scaled to the actual build plate, so when sizing up or down you can check the size and placement of the print with the build plate.

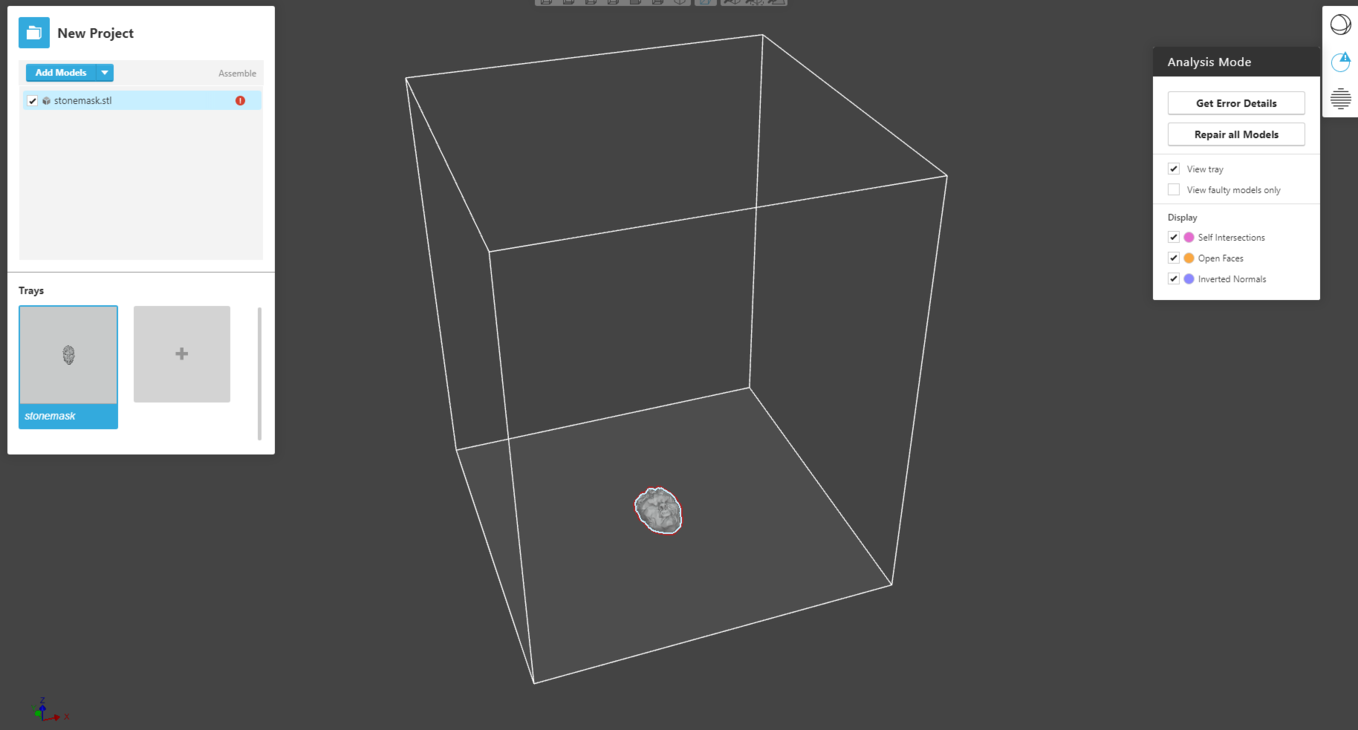

After opening and correctly orienting your part, you may see a red error like the one in the image above, to fix this, click analysis mode, the second icon from the top. The image below shows analysis mode, which quickly troubleshoots any problems with your file and shows any potential errors your part could have. To quickly fix your part, click Repair all Models which fix most problems with your model.

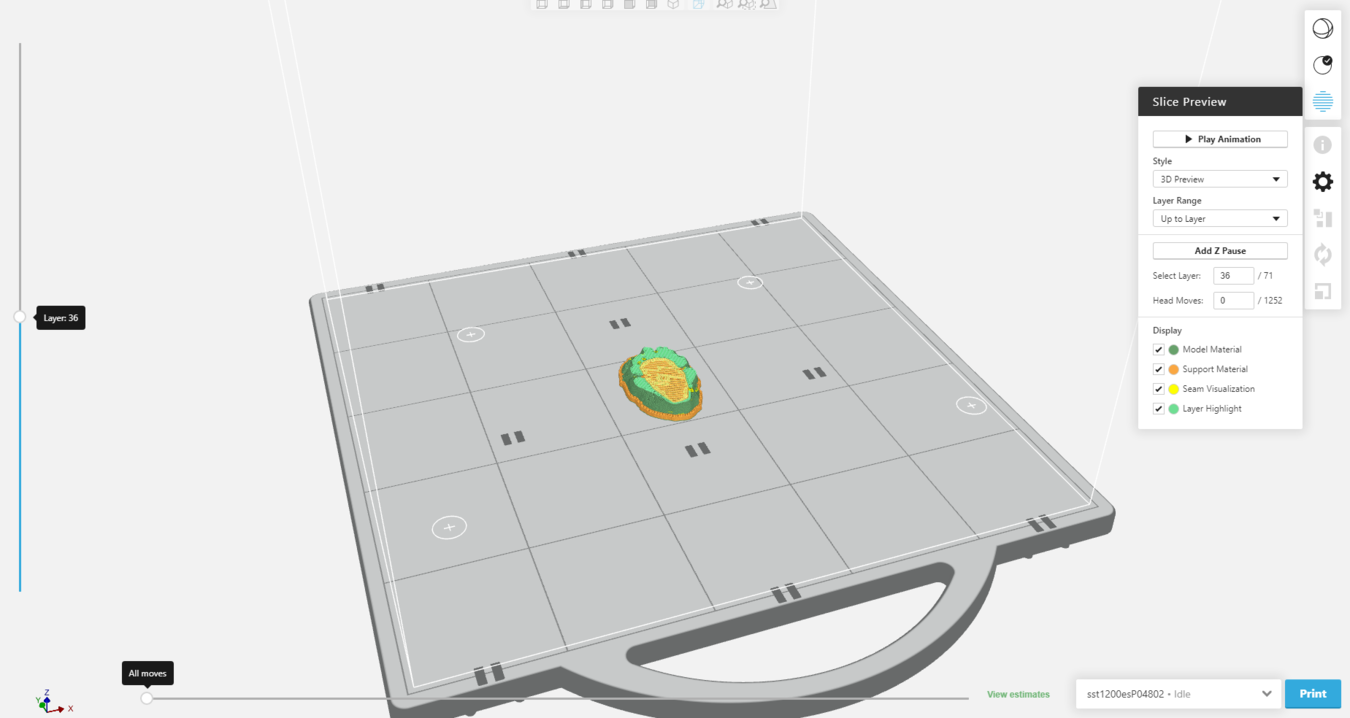

After repairing your part, click Slice Preview to see how the Dimension will print your part, total layers, and path of the nozzle. Inspect your part to ensure that it will print correctly, and has a low chance of failing. You can watch an animation of your part being built, layer by layer, and do other analysis before printing. Click View Estimates, found in green near the bottom right corner, to see an approximation of how long the print will take, and the amount of material used. Be sure that this information is recorded in the Job Log. Fix any potential problems that you may have seen, and when you are sure that the part is correctly oriented on the build plate. You may now click Print, locate on the bottom right of the screen. Note: Very rarely will a single part be printed on the Dimension or F370, do not start a print without other parts unless cleared by the lab helper.

Printing

Acid Bath

The Acid Bath is a heated tank of a Sodium Hydroxide and Water mixture, used to remove support material from parts printed on the Dimension and F370 Printers. The Acid Bath is to only be used by those trained in the Prototype Lab.

Mentors Only

This section will be for information that pertains only to Aces and Mentors.