Difference between revisions of "Finishing Room"

| (62 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | The Finishing Room is a well ventilated room that is a great place for dirty work | + | [[File:Finishing Room Logo.png|300px|frameless|left]][[File:Finishing Room.jpg|400px|thumb|right|The Finishing Room]] |

| + | The Finishing Room is a well ventilated room that is a great place for dirty work such as painting, staining, sanding, etc. | ||

| − | The current Aces of the {{PAGENAME}} are '''{{#show: {{PAGENAME}} |?Has ace.Has name}}''' ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). | + | The current Aces of the {{PAGENAME}} are '''{{#show: {{PAGENAME}} |?Has ace.Has name}}''' ({{#show: {{PAGENAME}} |?Has ace.Has email address}}). |

| + | |||

| + | {{#set: | ||

| + | |is facility = True | ||

| + | |Has ace=Needed;Makerhub@georgefox.edu | ||

| + | }} | ||

__TOC__ | __TOC__ | ||

| − | =Schedule= | + | ==Schedule== |

| − | |||

| + | This room is available during [[Machine Shop#Schedule|Machine Shop]] hours. | ||

| − | =Equipment Overview = | + | ==Equipment Overview== |

{{#ask: | {{#ask: | ||

[[Is equipment::true]] | [[Is equipment::true]] | ||

| Line 20: | Line 26: | ||

}} | }} | ||

| − | ==[[ | + | ==Equipment by Icon== |

| + | |||

| + | {{#ask: | ||

| + | [[Is equipment::True]][[Has icon::+]] [[Is located in facility::Finishing Room]] | ||

| + | |?Has icon=Icon | ||

| + | |?Is located in facility | ||

| + | |format=plainlist | ||

| + | |template=EquipmentIconGallery | ||

| + | |outrotemplate=EquipmentIconGalleryOutro | ||

| + | |limit=100 | ||

| + | |link=none | ||

| + | |sort=Is located in facility | ||

| + | }} | ||

| + | |||

| + | Air brush, air sander, HVLP gun, etc. | ||

| + | |||

| + | =Description= | ||

| + | |||

| + | The {{PAGENAME}} is space where Maker Hub users can paint, stain, dye, sand, mix resins/epoxies, and apply finishes to a workpiece. The ventilation system pulls 4 exchanges of air per hour which helps minimize a user's exposure to toxic fumes, dust, and other respiratory harms. During operations, ventilation must be continuous during spray or sanding operations and for a sufficient time after operations have stopped to allow the vapors from drying coated materials, dust from sanding to settle, and residue to be completely exhausted. Work shall be positioned as far back as possible into the paint booth for the booth to provide adequate protection to the user. | ||

| + | |||

| + | The room is supplied with compressed air for air brushing/spraying. Unless you are certified on the air brush, all painting should be done with a rattle can. For legal reasons, GFU employees cannot recommend specific respirators for any painting, spraying, or dusty activities you might perform. Finishing Room users are welcome to bring their own respirators or dust masks, but they must conduct their own research on which respirators/masks they should use to protect them from the fumes and/or dust they will be creating. There are N95 and P95 masks available from the [[Tool Room]] for users to wear in the Finishing Room. | ||

| + | Potential health hazards include exposure to chemicals such as paints (aerosol paint cans, stains, varnishes, latex or water based paint), silicas, or fine dust from sanding operations. An individual may be exposed through inhalation or dermal absorption. Organic solvents and vapors through inhalation or absorption have been linked to central nervous system disorders. In addition, skin contact may cause dermatitis and localized skin irritation. Exposure to additives and paint pigments such as lead, cadmium, and chromium is considered highly toxic. Sanding operations create fine dust that can have negative health effects if inhaled. Know the hazards involved with the materials you are using, check any applicable SDS sheets, and read any labels for proper usage instructions. ''Are the vapors or dust harmful to breathe? Is it flammable? Will there be a chemical reaction?'' Please do your research and notify the Maker Hub staff of any harmful chemicals, vapors, or dust you might be creating <strong>BEFORE</strong> you begin your work in the Finishing Room. | ||

| + | =[[3 commandments|3 Commandments]]= | ||

| − | == | + | ==Safety First== |

| − | Safety First is the | + | [[File:Safety First HD2.png|left|150px]] |

| + | Here are some safety instructions for the {{PAGENAME}}. Remember... SAFETY FIRST!!! | ||

| + | * All of the [[Machine_Shop#Safety_First|Machine Shop]] safety guidelines apply for the {{PAGENAME}}. This includes the shop attire requirements. | ||

| + | * Wear personal protective equipment (PPE) such as eye/face protection, ear protection, gloves, protective clothing, and a respirator or dust mask. | ||

| + | * Wear <strong>SAFETY GLASSES</strong> when working in the {{PAGENAME}}. It does not matter that you are outside the "safety glasses zone" taped on the Machine Shop floor. | ||

| + | * Ear protection must be worn when the exhaust system is on. Ear plugs are available at the safety station by the Wood Shop door. | ||

| + | * Minimize skin contact when working with paint, resins, epoxies, stains, dyes, finishes, or other chemicals. Wear gloves and protective clothing as needed. Gloves are available at the safety station by the Wood Shop door. | ||

| + | * Never point a spray paint can or air brush at any part of your body. | ||

| + | * If any liquids, sprays, or particulates get in your eyes, use the eye wash station at the sinks by the Machine Shop door to flush the material out of your eyes. | ||

| + | * Read the label on any paints or chemicals you use and understand what hazards you need to avoid/consider. If sanding or creating dust, do your research to know what respiratory hazards are present and how to minimize them. | ||

| + | * Absolutely no open flames or heat-creating activities (e.g. heat guns) are allowed in the {{PAGENAME}}. Certain paints, lacquers, varnishes, shellacs, solvents, and thinners are extremely flammable and can cause a fire. | ||

| + | * If the product you are using specifies that a respirator is needed, the user must follow the [https://docs.google.com/document/d/18KAcs4N3NI-fGlEox7J6ZxNMsjGrcqNTvbdYm0xcGaw/edit?usp=sharing George Fox University Voluntary Respiratory Protection Plan]. | ||

| + | * Do not stand downwind of your workpiece. The whole point of the {{PAGENAME}} is to pull harmful fumes and dust away from you, through the filters, and out of the building. If you are standing between your workpiece and the filters, you are defeating the purpose of the {{PAGENAME}} because all the fumes and dust you are creating are being pulled past your body on their way out of the building. Rotate your workpiece if you need to access the other side. | ||

| + | * Allow freshly painted, sprayed, or curing items to dry in the {{PAGENAME}} with the exhaust ventilation system operating (but not overnight). Notify a shop supervisor if you intend to leave the ventilation system operating for a set period of time. Set a reminder for yourself to return after your workpiece has dried, turn off the ventilation system, and reset the space. | ||

| + | *Do not attempt to operate any equipment without being certified by the ace, Machine Shop staff, or a Maker Hub employee. | ||

| + | * Wash your hands thoroughly after using the {{PAGENAME}}. | ||

| + | * Food or drink is not allowed in the {{PAGENAME}}. | ||

| − | + | ===Fire Protection System=== | |

| − | The | + | The paint booth is designed with an AMEREX industrial dry chemical fire suppression system that will discharge into the paint booth if the system is set off. Trust me... you do not want to set off this fire suppression system unless absolutely necessary because it will unleash a deluge of fire suppressing agent all over you, your workpiece, and probably half of the Machine Shop. The fire suppression system can be activated by automatic or manual means (see the images in the gallery below). During automatic activation, the heat from the fire melts a pressurized detection line relieving air pressure, which allows high-pressure nitrogen gas to pneumatically open the dry chemical cylinders to disperse the suppressing agent through the fixed nozzle network. During manual activation, the user must first pull the ring pin located at the entrance to the Finishing Room and then pull the handle of the manual pull station firmly. As iterated above, do not use any open flames or create a lot of heat inside the paint booth. If possible, your first option should always be to use the portable fire extinguisher by the Wood Shop door before manually activating the fire suppression system. Treat the fire suppression system as the last resort for when the fire has gotten out of control. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Note: The discharge of the fire suppression system is noisy and produces a large cloud of extinguishing chemicals. Breathing the dry chemical is unpleasant and may cause some irritation to the nose, throat, and eyes, and may cause coughing. The dry chemical is non-toxic in all forms and is classified as nuisance dust by OSHA. | |

| − | |||

| − | + | <br> | |

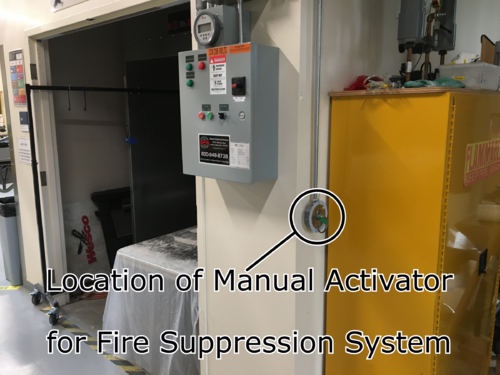

| + | <gallery mode="packed" heights="250px"> | ||

| + | Image:FR Auto Activation.png|<span style="font-size:medium;">Automatic Activation</span> | ||

| + | Image:FR Manual Activation.png|<span style="font-size:medium;">Manual Activation</span> | ||

| + | Image:FR Manual Activation Location.png|<span style="font-size:medium;">Where to Find the Manual Activation</span> | ||

| + | </gallery> | ||

| − | + | ====In Case of a Fire==== | |

| − | |||

| − | + | The following steps are required if the fire suppression system is activated: | |

| + | # Alert anyone nearby of the fire and fire suppression system activation. | ||

| + | # Alert the Maker Hub Technician or Maker Hub Manager of the fire and fire suppression system activation. | ||

| + | # Evacuate all employees, students, and volunteers from the space. | ||

| + | # Notify the fire department by dialing 911. | ||

| + | # Stand by with a portable fire extinguisher and watch for re-ignition of the fire. | ||

| − | + | ====After the Fire is Out==== | |

| − | + | The following safety precautions shall be followed: | |

| + | * DO NOT restart the fire suppression system. It must be serviced and recharged by certified personnel. | ||

| + | * DO NOT use any equipment that may have been exposed to the suppressing agent. All exposed equipment must be inspected and cleaned per the manufacturers' specifications. | ||

| − | === | + | ==Reset the Space== |

| − | + | [[File:FR Control Panel.png|400px|thumb|right|Finishing Room Control Panel]] | |

| + | Remember to address these details when resetting the space in the {{PAGENAME}}: | ||

| + | * The Finishing Room is not a storage place for your project. Unless your workpiece is actively drying... AND you've notified the Machine Shop supervisor... AND you've set a reminder for yourself to return later to remove your workpiece once it is dry... Don't leave your workpiece in the Finishing Room. | ||

| + | * Do not leave any paint cans, finishing products, rags, or other chemicals in the Finishing Room. | ||

| + | * IMPORTANT: If you are using certain wood stains or other products that are known to spontaneously combust, talk to Justin or Nick about the proper way to dispose of your oily rags and paper towels so that you won't start a fire. | ||

| + | * Clean up any spills, dust, or debris left behind in the Finishing Room. | ||

| + | * Put away any unused materials and throw away any unusable scrap. | ||

| + | * Put the equipment back the way you found it. The compressed air line should be coiled up neatly. | ||

| + | * Unless you are intentionally leaving the ventilation system on while your workpiece dries... AND you have notified the Machine Shop supervisor... AND you set a reminder for yourself to return later to shut off the ventilation system before the Machine Shop closes for the day... Don't forget to shut off the ventilation system when you are done working in the Finishing Room. (Are you noticing a pattern here???) | ||

| + | * Don't forget to turn off the power switch on the control panel by turning the knob to "OFF" when you are done (see the image to the right). | ||

| + | * There are two light switches for the Finishing Room -- one for the paint booth and one for the Finishing Room itself. The paint booth light is located on the control panel, and the Finishing Room light is located on the wall that leads toward the Wood Shop. Please make sure both of these lights are turned off when you are done working in the Finishing Room. | ||

| − | + | Put anything you use back where it belongs. There is a place for everything and everything has a place. This rule applies to everything in the space. If you use a tool, put it back. If you use a pen, put it back. Do not leave your projects in the room unless you have made prior arrangements. Throw away your trash and recycling. | |

| − | + | Now, we understand that sometimes you need to leave projects out. Maybe you are in the middle of a large project and the paint needs to dry overnight. In cases like this, it is okay, but you NEED to make prior arrangements with Justin or Nick. | |

| − | + | Always leave the space better than you found it. | |

| − | + | ===Be Professional=== | |

| − | + | This commandment has two sides to it. It covers the idea of acting like professional (which Webster’s defines as “exhibiting a courteous, conscientious, and generally businesslike manner in the workplace”). The term also describes the standards of education and training that prepare members of the profession with the particular knowledge and skills necessary to perform their specific role within that profession. Hopefully, you are learning both of these as part of your education at George Fox University. In the Finishing Room we expect you to develop as a courteous, conscientious, and skilled craftsman, understanding the tools and equipment in the Maker Hub and how to use them effectively. | |

| − | |||

| − | + | Being a professional has some obvious ramifications in terms of behavior. First, be Christlike. Think of others as better than yourself. Share. If you have been occupying the Finishing Room for a while and someone else is waiting to use the space, let them use it for a while. This is being a professional. | |

| − | |||

| − | |||

| − | |||

| − | + | If you are learning to paint or sand, and you can't get something to work the way you want - ASK SOMEONE! Learn! Become a professional. Learn the craft. This is an educational space. You might think it will be quicker for you to just get it done “your” way and not learn how to do something correctly. Be a Professional and learn the proper way, and then be available to teach others. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | One very important, and likely difficult, part of being a professional is correcting others when they are not being professional. It is your responsibility to speak up when you see somebody doing something inappropriate. If you see somebody doing something unsafe the Christlike way to care for them is to let them know they're not safe. This is one of many ways to love our neighbor. If someone is not resetting the space or being unprofessional, the professional thing to do is to remind them of the three commandments and ask them politely to correct their actions. This is OUR space, not any individual's. As a group, we expect everyone in the space to keep the space safe, clean, and operable for everyone. | ||

| − | + | If someone acts unprofessionally in the Finishing Room, you are welcome to bring the issue to Justin or Nick's attention. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | ==== | + | ==General Finishing Room Knowledge== |

| − | |||

| − | + | George Fox University takes special precautions while handling, storing, and disposing of paint material. Before using any product, read the label carefully. Never use any paint product that has a missing or unreadable label. The user is responsible for wearing appropriate personal protective equipment such as goggles or safety glasses and gloves. | |

| − | + | Talk to Justin or Nick about storing your paint products or other chemicals in the flammables cabinet. All aerosol or flammable paint must be stored when not in use in a flammable cabinet located to the right of the paint booth. Cabinet must remain closed at all times. Storage of water-based latex paint is exempt from these storage requirements. Paint lids or aerosol can caps must be closed tightly. | |

| − | + | George Fox University disposes of paint per its Waste Management Plan. Aerosol paint cans must be delivered to Plant Services for puncturing. All latex paint is disposed of in accordance with the Oregon PaintCare program. If the paint canister is empty, it may be thrown in the dumpster. | |

| − | + | Any other operations such as cutting, grinding, or sanding inside the paint booth must not create a flammable hazard. Fine dust created by sanding can be a fire and explosion hazard. Users must clean fine dust daily to prevent buildup. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{{#ask: | {{#ask: | ||

| Line 128: | Line 148: | ||

}} | }} | ||

| − | == | + | ==Certification== |

| − | + | Complete the <strong>{{PAGENAME}} Certification Quiz Module</strong> at the link below to gain access to the {{PAGENAME}}. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email <span style="color:blue">makerhub@georgefox.edu</span> if you have any questions. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [https://georgefox.instructure.com/enroll/GH36RT Maker Hub Canvas Course] | |

| − | |||

| − | |||

Latest revision as of 13:50, 22 August 2024

The Finishing Room is a well ventilated room that is a great place for dirty work such as painting, staining, sanding, etc.

The current Aces of the Finishing Room are Needed (Makerhub@georgefox.edu).

Schedule

This room is available during Machine Shop hours.

Equipment Overview

Equipment by Icon

Air brush, air sander, HVLP gun, etc.

Description

The Finishing Room is space where Maker Hub users can paint, stain, dye, sand, mix resins/epoxies, and apply finishes to a workpiece. The ventilation system pulls 4 exchanges of air per hour which helps minimize a user's exposure to toxic fumes, dust, and other respiratory harms. During operations, ventilation must be continuous during spray or sanding operations and for a sufficient time after operations have stopped to allow the vapors from drying coated materials, dust from sanding to settle, and residue to be completely exhausted. Work shall be positioned as far back as possible into the paint booth for the booth to provide adequate protection to the user.

The room is supplied with compressed air for air brushing/spraying. Unless you are certified on the air brush, all painting should be done with a rattle can. For legal reasons, GFU employees cannot recommend specific respirators for any painting, spraying, or dusty activities you might perform. Finishing Room users are welcome to bring their own respirators or dust masks, but they must conduct their own research on which respirators/masks they should use to protect them from the fumes and/or dust they will be creating. There are N95 and P95 masks available from the Tool Room for users to wear in the Finishing Room.

Potential health hazards include exposure to chemicals such as paints (aerosol paint cans, stains, varnishes, latex or water based paint), silicas, or fine dust from sanding operations. An individual may be exposed through inhalation or dermal absorption. Organic solvents and vapors through inhalation or absorption have been linked to central nervous system disorders. In addition, skin contact may cause dermatitis and localized skin irritation. Exposure to additives and paint pigments such as lead, cadmium, and chromium is considered highly toxic. Sanding operations create fine dust that can have negative health effects if inhaled. Know the hazards involved with the materials you are using, check any applicable SDS sheets, and read any labels for proper usage instructions. Are the vapors or dust harmful to breathe? Is it flammable? Will there be a chemical reaction? Please do your research and notify the Maker Hub staff of any harmful chemicals, vapors, or dust you might be creating BEFORE you begin your work in the Finishing Room.

3 Commandments

Safety First

Here are some safety instructions for the Finishing Room. Remember... SAFETY FIRST!!!

- All of the Machine Shop safety guidelines apply for the Finishing Room. This includes the shop attire requirements.

- Wear personal protective equipment (PPE) such as eye/face protection, ear protection, gloves, protective clothing, and a respirator or dust mask.

- Wear SAFETY GLASSES when working in the Finishing Room. It does not matter that you are outside the "safety glasses zone" taped on the Machine Shop floor.

- Ear protection must be worn when the exhaust system is on. Ear plugs are available at the safety station by the Wood Shop door.

- Minimize skin contact when working with paint, resins, epoxies, stains, dyes, finishes, or other chemicals. Wear gloves and protective clothing as needed. Gloves are available at the safety station by the Wood Shop door.

- Never point a spray paint can or air brush at any part of your body.

- If any liquids, sprays, or particulates get in your eyes, use the eye wash station at the sinks by the Machine Shop door to flush the material out of your eyes.

- Read the label on any paints or chemicals you use and understand what hazards you need to avoid/consider. If sanding or creating dust, do your research to know what respiratory hazards are present and how to minimize them.

- Absolutely no open flames or heat-creating activities (e.g. heat guns) are allowed in the Finishing Room. Certain paints, lacquers, varnishes, shellacs, solvents, and thinners are extremely flammable and can cause a fire.

- If the product you are using specifies that a respirator is needed, the user must follow the George Fox University Voluntary Respiratory Protection Plan.

- Do not stand downwind of your workpiece. The whole point of the Finishing Room is to pull harmful fumes and dust away from you, through the filters, and out of the building. If you are standing between your workpiece and the filters, you are defeating the purpose of the Finishing Room because all the fumes and dust you are creating are being pulled past your body on their way out of the building. Rotate your workpiece if you need to access the other side.

- Allow freshly painted, sprayed, or curing items to dry in the Finishing Room with the exhaust ventilation system operating (but not overnight). Notify a shop supervisor if you intend to leave the ventilation system operating for a set period of time. Set a reminder for yourself to return after your workpiece has dried, turn off the ventilation system, and reset the space.

- Do not attempt to operate any equipment without being certified by the ace, Machine Shop staff, or a Maker Hub employee.

- Wash your hands thoroughly after using the Finishing Room.

- Food or drink is not allowed in the Finishing Room.

Fire Protection System

The paint booth is designed with an AMEREX industrial dry chemical fire suppression system that will discharge into the paint booth if the system is set off. Trust me... you do not want to set off this fire suppression system unless absolutely necessary because it will unleash a deluge of fire suppressing agent all over you, your workpiece, and probably half of the Machine Shop. The fire suppression system can be activated by automatic or manual means (see the images in the gallery below). During automatic activation, the heat from the fire melts a pressurized detection line relieving air pressure, which allows high-pressure nitrogen gas to pneumatically open the dry chemical cylinders to disperse the suppressing agent through the fixed nozzle network. During manual activation, the user must first pull the ring pin located at the entrance to the Finishing Room and then pull the handle of the manual pull station firmly. As iterated above, do not use any open flames or create a lot of heat inside the paint booth. If possible, your first option should always be to use the portable fire extinguisher by the Wood Shop door before manually activating the fire suppression system. Treat the fire suppression system as the last resort for when the fire has gotten out of control.

Note: The discharge of the fire suppression system is noisy and produces a large cloud of extinguishing chemicals. Breathing the dry chemical is unpleasant and may cause some irritation to the nose, throat, and eyes, and may cause coughing. The dry chemical is non-toxic in all forms and is classified as nuisance dust by OSHA.

In Case of a Fire

The following steps are required if the fire suppression system is activated:

- Alert anyone nearby of the fire and fire suppression system activation.

- Alert the Maker Hub Technician or Maker Hub Manager of the fire and fire suppression system activation.

- Evacuate all employees, students, and volunteers from the space.

- Notify the fire department by dialing 911.

- Stand by with a portable fire extinguisher and watch for re-ignition of the fire.

After the Fire is Out

The following safety precautions shall be followed:

- DO NOT restart the fire suppression system. It must be serviced and recharged by certified personnel.

- DO NOT use any equipment that may have been exposed to the suppressing agent. All exposed equipment must be inspected and cleaned per the manufacturers' specifications.

Reset the Space

Remember to address these details when resetting the space in the Finishing Room:

- The Finishing Room is not a storage place for your project. Unless your workpiece is actively drying... AND you've notified the Machine Shop supervisor... AND you've set a reminder for yourself to return later to remove your workpiece once it is dry... Don't leave your workpiece in the Finishing Room.

- Do not leave any paint cans, finishing products, rags, or other chemicals in the Finishing Room.

- IMPORTANT: If you are using certain wood stains or other products that are known to spontaneously combust, talk to Justin or Nick about the proper way to dispose of your oily rags and paper towels so that you won't start a fire.

- Clean up any spills, dust, or debris left behind in the Finishing Room.

- Put away any unused materials and throw away any unusable scrap.

- Put the equipment back the way you found it. The compressed air line should be coiled up neatly.

- Unless you are intentionally leaving the ventilation system on while your workpiece dries... AND you have notified the Machine Shop supervisor... AND you set a reminder for yourself to return later to shut off the ventilation system before the Machine Shop closes for the day... Don't forget to shut off the ventilation system when you are done working in the Finishing Room. (Are you noticing a pattern here???)

- Don't forget to turn off the power switch on the control panel by turning the knob to "OFF" when you are done (see the image to the right).

- There are two light switches for the Finishing Room -- one for the paint booth and one for the Finishing Room itself. The paint booth light is located on the control panel, and the Finishing Room light is located on the wall that leads toward the Wood Shop. Please make sure both of these lights are turned off when you are done working in the Finishing Room.

Put anything you use back where it belongs. There is a place for everything and everything has a place. This rule applies to everything in the space. If you use a tool, put it back. If you use a pen, put it back. Do not leave your projects in the room unless you have made prior arrangements. Throw away your trash and recycling.

Now, we understand that sometimes you need to leave projects out. Maybe you are in the middle of a large project and the paint needs to dry overnight. In cases like this, it is okay, but you NEED to make prior arrangements with Justin or Nick.

Always leave the space better than you found it.

Be Professional

This commandment has two sides to it. It covers the idea of acting like professional (which Webster’s defines as “exhibiting a courteous, conscientious, and generally businesslike manner in the workplace”). The term also describes the standards of education and training that prepare members of the profession with the particular knowledge and skills necessary to perform their specific role within that profession. Hopefully, you are learning both of these as part of your education at George Fox University. In the Finishing Room we expect you to develop as a courteous, conscientious, and skilled craftsman, understanding the tools and equipment in the Maker Hub and how to use them effectively.

Being a professional has some obvious ramifications in terms of behavior. First, be Christlike. Think of others as better than yourself. Share. If you have been occupying the Finishing Room for a while and someone else is waiting to use the space, let them use it for a while. This is being a professional.

If you are learning to paint or sand, and you can't get something to work the way you want - ASK SOMEONE! Learn! Become a professional. Learn the craft. This is an educational space. You might think it will be quicker for you to just get it done “your” way and not learn how to do something correctly. Be a Professional and learn the proper way, and then be available to teach others.

One very important, and likely difficult, part of being a professional is correcting others when they are not being professional. It is your responsibility to speak up when you see somebody doing something inappropriate. If you see somebody doing something unsafe the Christlike way to care for them is to let them know they're not safe. This is one of many ways to love our neighbor. If someone is not resetting the space or being unprofessional, the professional thing to do is to remind them of the three commandments and ask them politely to correct their actions. This is OUR space, not any individual's. As a group, we expect everyone in the space to keep the space safe, clean, and operable for everyone.

If someone acts unprofessionally in the Finishing Room, you are welcome to bring the issue to Justin or Nick's attention.

General Finishing Room Knowledge

George Fox University takes special precautions while handling, storing, and disposing of paint material. Before using any product, read the label carefully. Never use any paint product that has a missing or unreadable label. The user is responsible for wearing appropriate personal protective equipment such as goggles or safety glasses and gloves.

Talk to Justin or Nick about storing your paint products or other chemicals in the flammables cabinet. All aerosol or flammable paint must be stored when not in use in a flammable cabinet located to the right of the paint booth. Cabinet must remain closed at all times. Storage of water-based latex paint is exempt from these storage requirements. Paint lids or aerosol can caps must be closed tightly.

George Fox University disposes of paint per its Waste Management Plan. Aerosol paint cans must be delivered to Plant Services for puncturing. All latex paint is disposed of in accordance with the Oregon PaintCare program. If the paint canister is empty, it may be thrown in the dumpster.

Any other operations such as cutting, grinding, or sanding inside the paint booth must not create a flammable hazard. Fine dust created by sanding can be a fire and explosion hazard. Users must clean fine dust daily to prevent buildup.

Certification

Complete the Finishing Room Certification Quiz Module at the link below to gain access to the Finishing Room. The Maker Hub Canvas course pertains to all facilities and equipment contained in the Maker Hub; simply complete the quizzes for the facilities/equipment you wish to use in the Maker Hub. Please email makerhub@georgefox.edu if you have any questions.